Muggins the Mug

Member

- Messages

- 231

fair enough, did you realy have to show the holes though

Nothing like showing everything, warts and all.

Regards,

Ian.

fair enough, did you realy have to show the holes though

I still need to work on slowing down though.

I still need to work on slowing down though. This welding lark is getting quite addictive.

This welding lark is getting quite addictive.

so go easy on the slagging

so go easy on the slagging

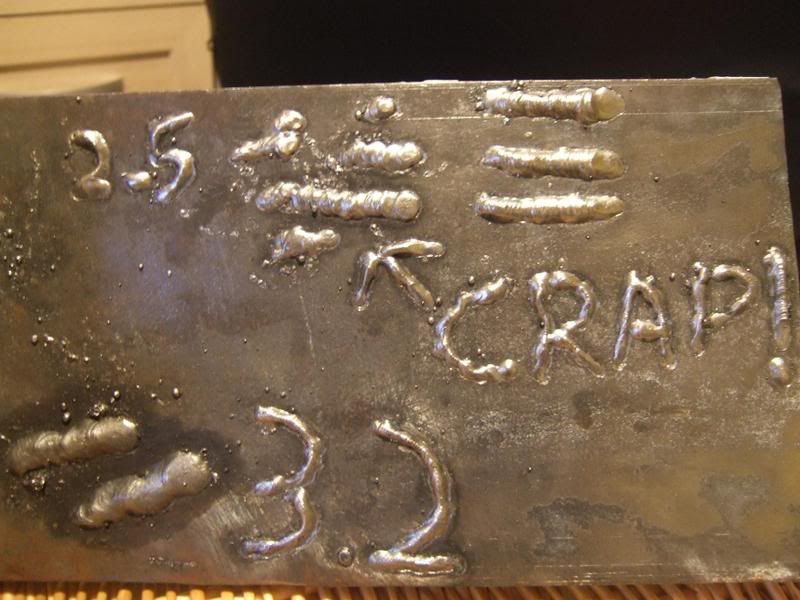

as promissed mr muggins i had a go at the sip's on my machine (ERP 180 turbo) just before i post the pictures lets just make this clear i am in no way shape or form a welder by tradeso go easy on the slagging

so there you go mr muggins, dont buy your rods from hellfrauds anymorethese things could put a learner off for life!

That's how you had to whack up the amps to get them to work.

That's how you had to whack up the amps to get them to work.

.......also if u now have your head a bit closer and can see your arc length use your ears as you can hear when it changes,i hate it when the shop is too noisy , good work keep practising ........Gav

.......also if u now have your head a bit closer and can see your arc length use your ears as you can hear when it changes,i hate it when the shop is too noisy , good work keep practising ........GavTry turning the current up a bit, say 90 - 95 amps, and use a touch welding technique, strike up and gently touch the electrode down on the plate then drag it along, the core will burn up inside the flux and give a cupping effect in the end of the rod, the depth of the cup will set the arc length. some more info in an older post here

Maybe try straightening the rod up a bit

I'm determined to steady my hand as well as looking into getting an auto darkening lid so that I can see where my striking point is. I think I'm frightened to go too slow as I tend to blow holes in the metal, as can be seen in the photos.

I'm determined to steady my hand as well as looking into getting an auto darkening lid so that I can see where my striking point is. I think I'm frightened to go too slow as I tend to blow holes in the metal, as can be seen in the photos. . I was shot through a shade 11 lens not ideal for camera, but what it does show is when i allow the arc to lengthen a little to much the arc becomes brighter, also you can here the change in sound. hopefully it might help you and a few others trying to learn the secret of arc welding

. I was shot through a shade 11 lens not ideal for camera, but what it does show is when i allow the arc to lengthen a little to much the arc becomes brighter, also you can here the change in sound. hopefully it might help you and a few others trying to learn the secret of arc weldingwell mug this is just for you lol, you dont realise how difficult it is to hold a camera in on hand and a welding rod in the other. I was shot through a shade 11 lens not ideal for camera, but what it does show is when i allow the arc to lengthen a little to much the arc becomes brighter, also you can here the change in sound. hopefully it might help you and a few others trying to learn the secret of arc welding

http://uk.youtube.com/watch?v=gjCnltle-Gs

what thickness is the metal your welding ian?