Dr.Al

Forum Supporter

- Messages

- 2,371

- Location

- Gloucestershire, UK

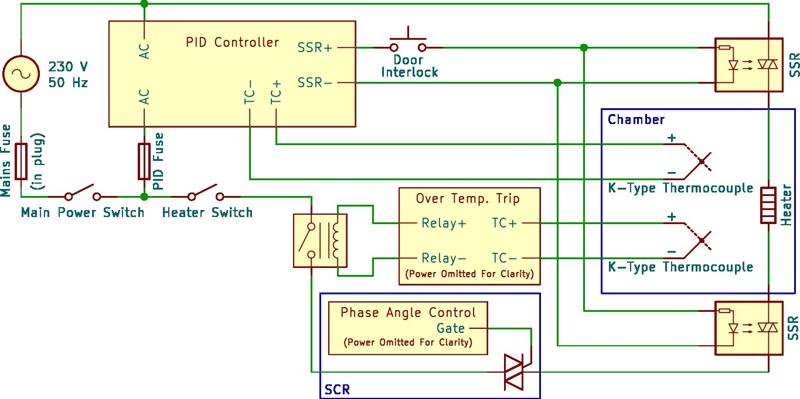

Thanks, that's useful. I'll plan for the second thermocouple & trip.FWIW, the common arrangement is a second thermocouple in the kiln connected to a separate over temperature trip that knocks the power off. It offers protection against T/C shorts, controller faults, etc. as well as SSR failure.

Worth having a programmable controller, I would have thought.

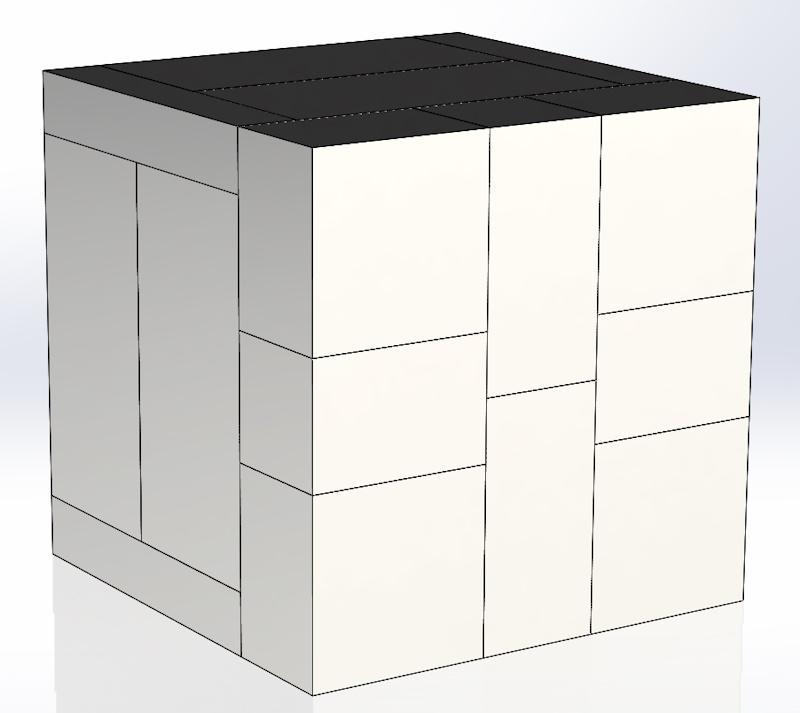

Personally, I wouldn't put sodium silicate anywhere near it - it will start to dissolve those bricks as a fairly low temperature (<<1000°C) and generally make a sticky mess. I really don't think you have to worry much about those bricks - they're easily abraded and become dusty, but put up with a lot of abuse otherwise. (Technical manager at a glass works for ~12 years.)

Understood that putting sodium silicate in the oven is bad, but what's sodium silicate & why would I be considering putting it near the oven?!

. A quick back-of-the-envelope calculation suggests it'll be okay (about 1.9 W/cm² which looks okay if I'm reading the right graph on the Kanthal website), but I'll write up my justification for that in a bit more detail.

. A quick back-of-the-envelope calculation suggests it'll be okay (about 1.9 W/cm² which looks okay if I'm reading the right graph on the Kanthal website), but I'll write up my justification for that in a bit more detail.