Dr.Al

Forum Supporter

- Messages

- 2,743

- Location

- Gloucestershire, UK

This is one of three projects I'm going to be writing up in parallel (the other two are described here and here). They'll each be running at very different paces, with two at the design stage while one is being made, but I thought I'd start posting updates on them all at the same time. I don't have space to work on multiple projects at the same time, but that doesn't stop me thinking and planning!

This is the least established of the three projects: the design is far from complete and I haven't started buying any of the materials yet. It's going to be quite a slow-burn project: I'll do a lot of thinking and designing gradually while I do other projects and I probably won't start work on the actual build for several months. Nevertheless I thought I'd start writing about it now: that way I'm more likely to get useful advice on the design while it can still be updated.

This project is an attempt to make a heat treatment oven. I definitely don't need a heat treatment oven: for the sort of work I typically do, I can get by with a blowtorch and a fair amount of patience. So why am I thinking of making a heat-treatment oven?

My usual approach to heat treatment is to do make a little tunnel from ceramic wool and use one or more blowtorches to heat the part. You can see an example of this in the following photo:

Judging the blade temperature is a combination of looking at the colour and testing it with a magnet. After testing, I usually stick it back in the flame for a bit to compensate for the temperature loss when testing it: it cools down quite quickly. All of that introduces quite a bit of variability.

Of course, I could just build a better frame (at bench height) and carry on using the blow torch, but if I'm going to do that, I might as well go the whole hog and try to build an electric oven.

I'm expecting the heat treatment oven to be a lot slower than the blowtorch approach. However, that extra time will be spent on the oven heating itself up rather than me squatting on the floor holding a blowtorch, so it should feel less like a chore.

My plan is to make it slightly unusual in that I'd like it to work in two orientations:

I'd like it to be relatively small and it's important that it's not too heavy. The oven won't have a permanent home in the workshop (as I have no space) so I need to be able to move it for storage. Also, I'll definitely need to use it outside if I'm doing brass casting (to give any zinc fumes freedom to escape; I'll also be wearing a respirator if/when I do this).

My initial sketches suggest the internal volume will be approximately 154 mm × 154 mm × 200 mm, although the depth (last measurement) might reduce a bit. When casting, there will be some sort of stand for the crucible to sit on (effectively reducing the depth a bit) so that the top of the crucible is accessible for tongs.

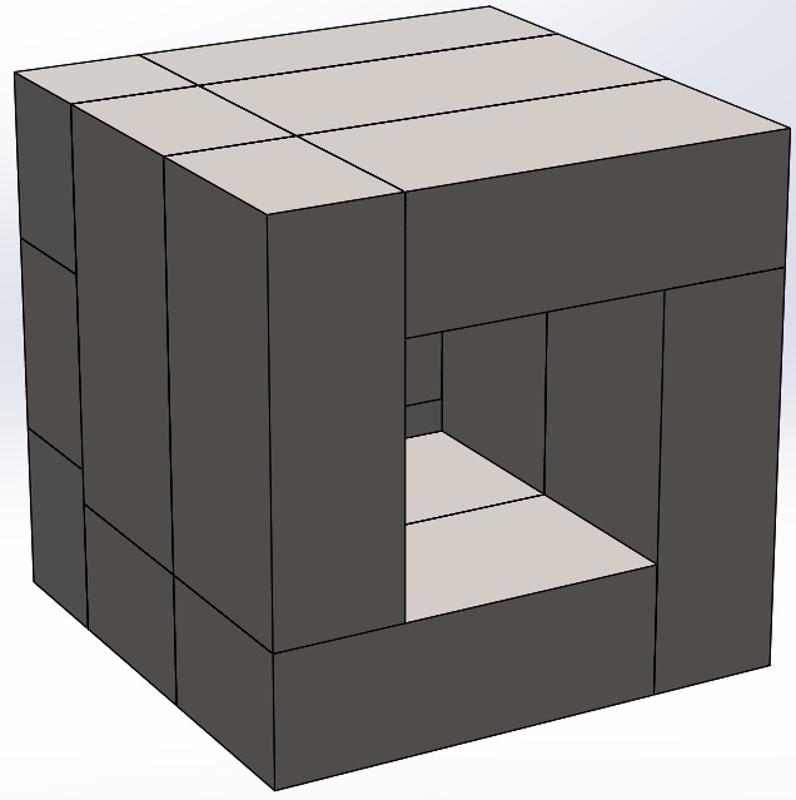

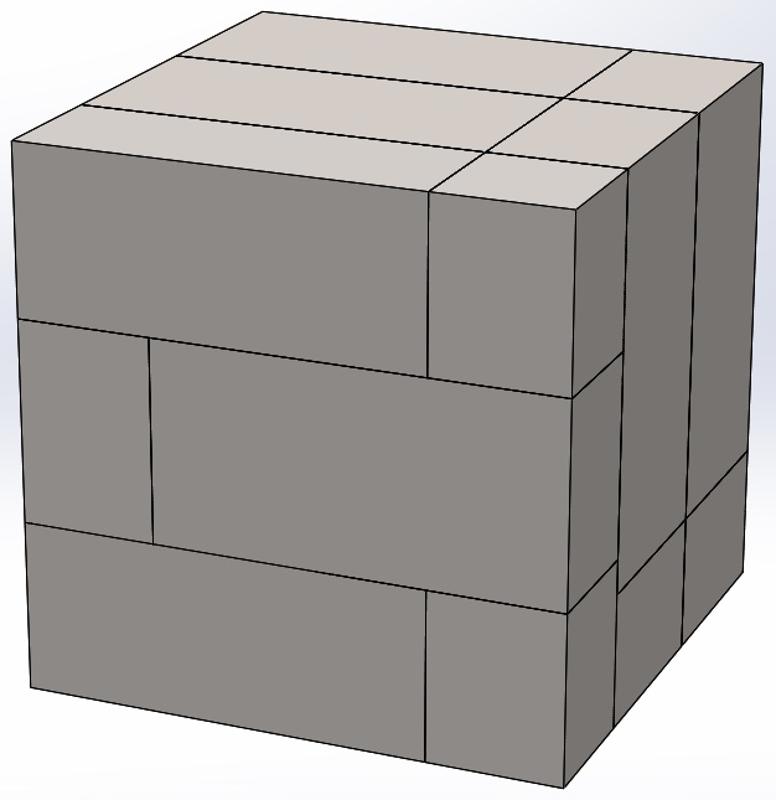

This CAD model image shows my current plan for the brick layout. The insulating fire bricks I'm expecting to use are 230 mm × 114 mm × 76 mm, and this layout gives 154 mm × 154 mm × 228 mm interior dimension. The door (not shown) will probably have a protrusion that goes into the opening a bit to improve the heat seal, hence the fact I'm expecting the internal volume to be slightly smaller.

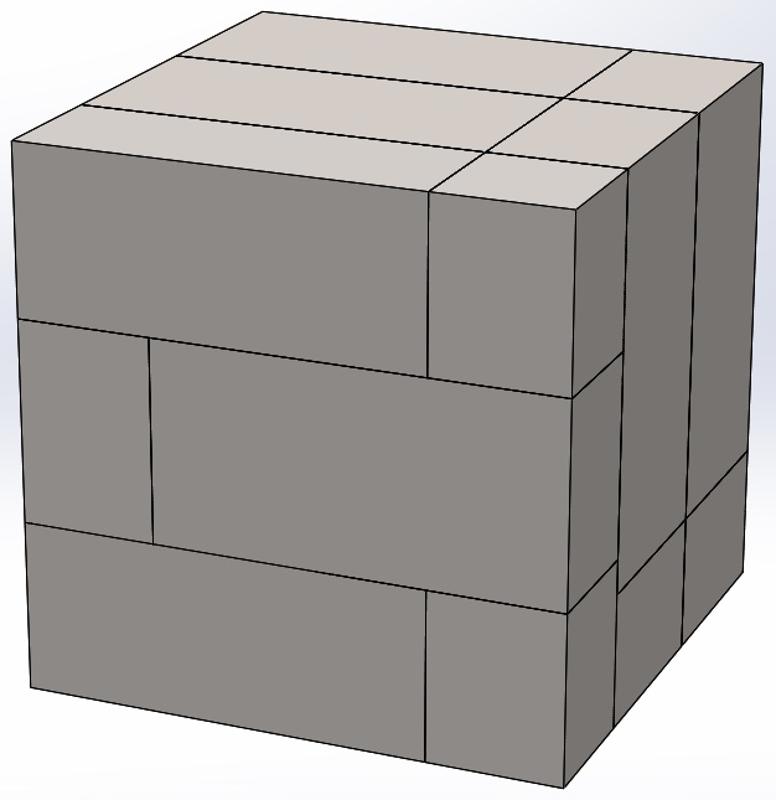

This CAD model image shows my current plan for the back face layout. The door will probably be laid out in much the same way. In theory, I can cut the three small bricks out of one full brick, but I'll buy extras in case it's necessary.

That's about as far as I've got so far: there's still a lot of designing and planning to go. It'll be a fair while before I get started making anything so I've got plenty of time for planning.

This is the least established of the three projects: the design is far from complete and I haven't started buying any of the materials yet. It's going to be quite a slow-burn project: I'll do a lot of thinking and designing gradually while I do other projects and I probably won't start work on the actual build for several months. Nevertheless I thought I'd start writing about it now: that way I'm more likely to get useful advice on the design while it can still be updated.

This project is an attempt to make a heat treatment oven. I definitely don't need a heat treatment oven: for the sort of work I typically do, I can get by with a blowtorch and a fair amount of patience. So why am I thinking of making a heat-treatment oven?

- As usual, I think it'll be an interesting project (and that's generally enough of a reason for me!)

- Most of the stuff I've heat treated in the past has been relatively small (d-bits, plough plane blades etc); however, as parts get thicker and with a longer cutting edge, it can take a long time (and a lot of gas) to get enough heat into the part to get it up to temperature. The time is not ideal as I'm usually squatting on the floor in an uncomfortable position to do the heat treatment!

- It should allow better control of temperature during hardening (and tempering?) so hopefully I'll be able to get more consistent results when hardening steel. On one occasion I also found that I hadn't managed to get the part hard enough (either due to not heating it enough during hardening or over-cooking it during tempering: I'm not sure which) and I had to start again. It could potentially also allow hardening of other materials (e.g. stainless steel) if I ever want to use them.

- I'm (optimistically) hoping that a heat treatment oven could also be used as a small furnace for melting brass and possibly bronze. I've got a lot of brass scrap stored in a drawer ready for a time when I can melt it down and turn it into something else. I'll probably end up just turning it into bar stock rather than anything complicated, but either way it needs a furnace of some sort to get it up to its melting point (930°C). Having something with good temperature control is probably a good thing for brass given the fact that zinc boils at a lower temperature (907°C) than brass melts.

- Did I mention that I think it'll be an interesting project?

My usual approach to heat treatment is to do make a little tunnel from ceramic wool and use one or more blowtorches to heat the part. You can see an example of this in the following photo:

Judging the blade temperature is a combination of looking at the colour and testing it with a magnet. After testing, I usually stick it back in the flame for a bit to compensate for the temperature loss when testing it: it cools down quite quickly. All of that introduces quite a bit of variability.

Of course, I could just build a better frame (at bench height) and carry on using the blow torch, but if I'm going to do that, I might as well go the whole hog and try to build an electric oven.

I'm expecting the heat treatment oven to be a lot slower than the blowtorch approach. However, that extra time will be spent on the oven heating itself up rather than me squatting on the floor holding a blowtorch, so it should feel less like a chore.

My plan is to make it slightly unusual in that I'd like it to work in two orientations:

- Horizontally, so the door opens like a cabinet door: this would be used when heat treating as it keeps as much heat as possible in the oven when you open the door and also means you aren't looking down into something that's kicking heat upwards.

- Vertically, with the door at the top: this would be used when casting with a crucible lowered into the oven (putting the crucible on its side would be rather messy!) This is going to involve a few careful design considerations to make sure a crucible sits in a position where I can get some tongs around it.

I'd like it to be relatively small and it's important that it's not too heavy. The oven won't have a permanent home in the workshop (as I have no space) so I need to be able to move it for storage. Also, I'll definitely need to use it outside if I'm doing brass casting (to give any zinc fumes freedom to escape; I'll also be wearing a respirator if/when I do this).

My initial sketches suggest the internal volume will be approximately 154 mm × 154 mm × 200 mm, although the depth (last measurement) might reduce a bit. When casting, there will be some sort of stand for the crucible to sit on (effectively reducing the depth a bit) so that the top of the crucible is accessible for tongs.

This CAD model image shows my current plan for the brick layout. The insulating fire bricks I'm expecting to use are 230 mm × 114 mm × 76 mm, and this layout gives 154 mm × 154 mm × 228 mm interior dimension. The door (not shown) will probably have a protrusion that goes into the opening a bit to improve the heat seal, hence the fact I'm expecting the internal volume to be slightly smaller.

This CAD model image shows my current plan for the back face layout. The door will probably be laid out in much the same way. In theory, I can cut the three small bricks out of one full brick, but I'll buy extras in case it's necessary.

That's about as far as I've got so far: there's still a lot of designing and planning to go. It'll be a fair while before I get started making anything so I've got plenty of time for planning.