normspanners

Member

- Messages

- 8,853

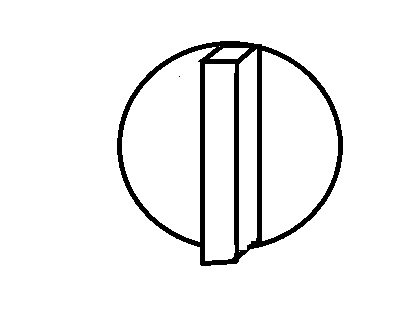

The fly wheel of the engine would be on the non joined side so that would stop it loosening, the joined crank would only be on the tightening side, 'tightening' into the flywheel of the first engine,also a taper+nut is what holds the flywheel on ! have you ever had to take a fly wheel off a small engine, you have to use a puller to split the taper.When one cylinder fires it will act to tighten the bolt, when the other fires it will act to loosen it. I can't see that holding even with a shallow .

A taper is the most accurate secure way of joining two shafts as long as both have been 'clocked' properly before machining they will have to be perfectly in line plus a little stud lock 643 and you would not loosen it.