You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Metal Melter

- Thread starter Onoff

- Start date

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,653

- Location

- Sevenoaks, UK

Feeling decidedly dodgy here this morning, nauseous plus both bound up and loose at the same time!

Luckily I've a late start / late finish so hopefully it'll pass. Just done a Covid test. Let's see where we are in 30 minutes!

Back on track...

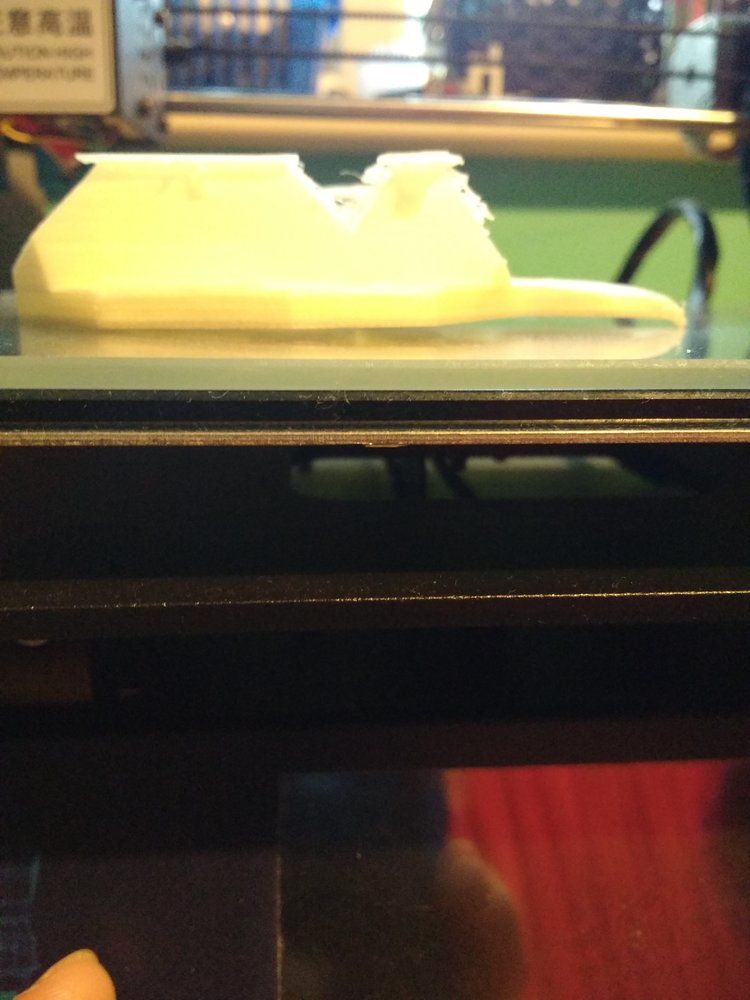

The PVA mould we had such high hopes for has a warp one end. A pity as the super lightweight supports came off a treat.

Where I'm pointing with the hex key is also a bit thin because of the warp.

Thinking to try and straighten it out with a bit of heat and even wet...could then print an add on to bring the thickness up and glue it on. The wax should find it's own level.

Luckily I've a late start / late finish so hopefully it'll pass. Just done a Covid test. Let's see where we are in 30 minutes!

Back on track...

The PVA mould we had such high hopes for has a warp one end. A pity as the super lightweight supports came off a treat.

Where I'm pointing with the hex key is also a bit thin because of the warp.

Thinking to try and straighten it out with a bit of heat and even wet...could then print an add on to bring the thickness up and glue it on. The wax should find it's own level.

prepman

Forum Supporter

- Messages

- 2,763

- Location

- Gwynedd UK

Added an extra ~30mm of refractory. Left it with the former (plastic paint tub) in overnight. Smoother finish. Slight struggle to get that out. The ideal former are those cheap flexible tote buckets with the handles.....but didn't have right sized one. Not ideal doing it in stages but ran out of refractory. Hopefully here on Mon-Tues. Nice fit for crucible

BTW the case for the furnace I made out ~4mm checker plate, without a suitable roller, so only approximately round.

BTW the case for the furnace I made out ~4mm checker plate, without a suitable roller, so only approximately round.

prepman

Forum Supporter

- Messages

- 2,763

- Location

- Gwynedd UK

I got my 3d printer a few years back specifically for pattern making for sand moulds, after seeing myfordboy on Youtube. Of course like most things.....still not attempted. Spent so much time fiddling with printer I lost track of the ultimate goal.I blame the idiot who started this. All so he can stand drunkenly at the bar and say "My boy did that...hic"

The investment plaster I have is "proper" casting stuff and very air permeable if that's the right word. I reckon a vacuum chamber is on the cards similar to the one VOG makes on his channel. I may knock one up shortly.

Pretty sure that as well as the plaster moulds being ultra dry you don't want air bubbles in the cast. From the videos I've watched if damp, it tends to turn the moisture to steam that then explodes up through the molten metal! Damaging to the finish as well as potentially dangerous. Ditto air pockets.

Though you can apparently achieve decent results getting the air out by holding a small sander against the side, I think I'll make a chamber for what it'll cost.

Here's a mad idea...I use a waterproofing admix when mixing mortar and concrete. It states on the label it has a de-aerator in it. Certainly cuts down on the tamping needed and makes for a lot less bubbles coming to the surface. I wonder if I could knock my plaster up with some of that in the water used?

Would that work or are the horns an issue? Moulded on edge might resolve it?

Last edited:

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,653

- Location

- Sevenoaks, UK

I got my 3d printer a few years back specifically for pattern making for sand moulds, after seeing myfordboy on Youtube. Of course like most things.....still not attempted. Spent so much time fiddling with printer I lost track of the ultimate goal.

Would that work or are the horns an issue? Moulded on edge might resolve it?

The horns and ears in the case of the cow we're trying to do, are in effect overhangs. You don't really see that sort of feature on traditional horse brasses which is why it appealed to me to try and do it.

Happy to be told wrong but I figured investment (plaster) casting was thus the way to go. Silicone moulds would likely work but not for the temperatures involved with brass.

With the overhangs we're into almost jewellery making as I see it and then lost wax / lost PLA, lost wax being the traditional jewellery method.

I might try another wax pour into the PVA mould later. The latest PVA mould isn't perfect as aforementioned. It does seem to have some warping issues as a process but I reckon my lad can figure that with more work on the supports.

Been out of it for the best part of yesterday and today with some stomach bug and the resulting dehydration headaches. Hopefully turned the corner now. Might feel up to pottering about in a bit!

prepman

Forum Supporter

- Messages

- 2,763

- Location

- Gwynedd UK

Good Luck and speedy recovery.The horns and ears in the case of the cow we're trying to do, are in effect overhangs. You don't really see that sort of feature on traditional horse brasses which is why it appealed to me to try and do it.

Happy to be told wrong but I figured investment (plaster) casting was thus the way to go. Silicone moulds would likely work but not for the temperatures involved with brass.

With the overhangs we're into almost jewellery making as I see it and then lost wax / lost PLA, lost wax being the traditional jewellery method.

I might try another wax pour into the PVA mould later. The latest PVA mould isn't perfect as aforementioned. It does seem to have some warping issues as a process but I reckon my lad can figure that with more work on the supports.

Been out of it for the best part of yesterday and today with some stomach bug and the resulting dehydration headaches. Hopefully turned the corner now. Might feel up to pottering about in a bit!

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,653

- Location

- Sevenoaks, UK

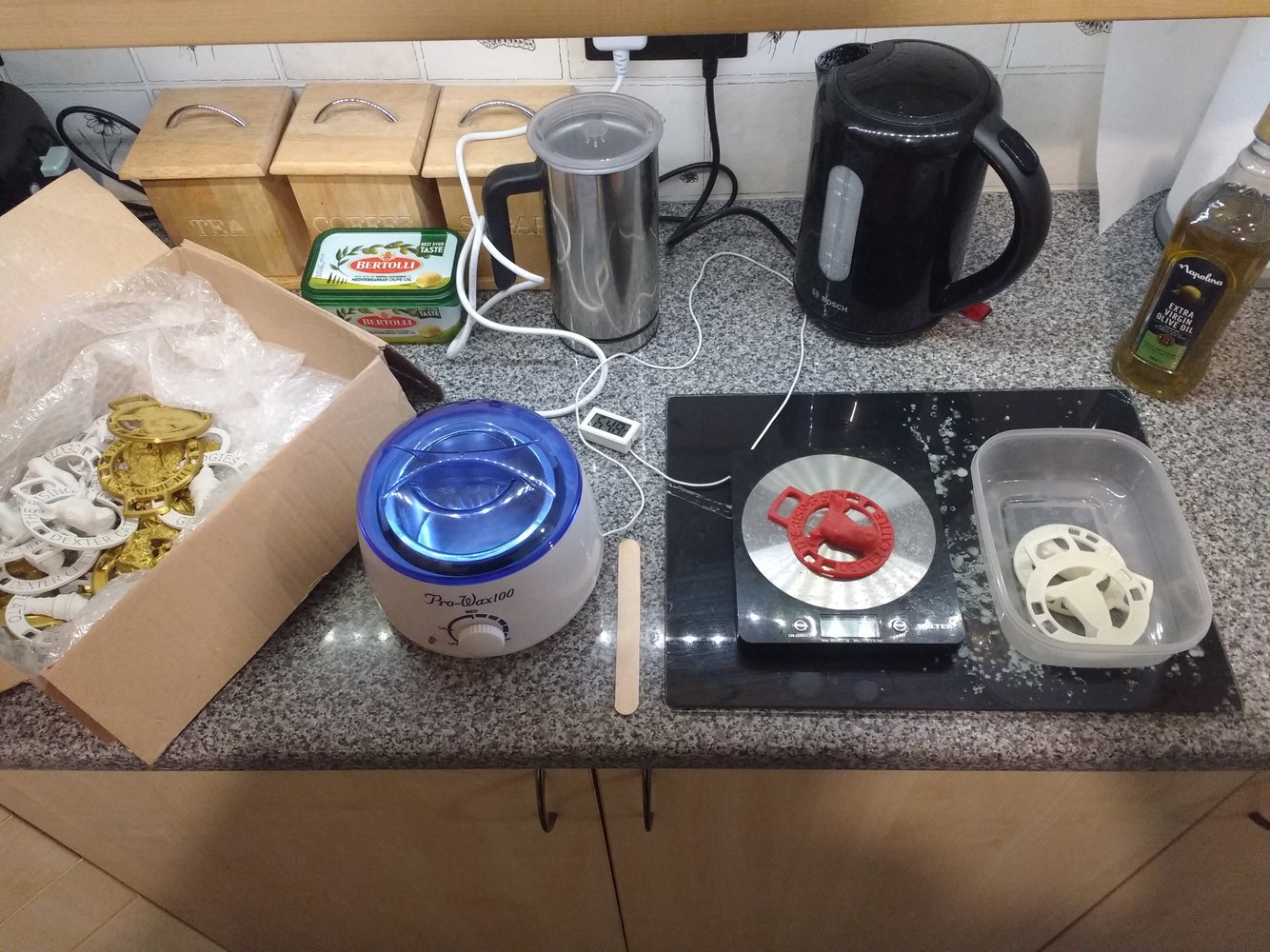

Wax cow No.1 being weighed and about to melted down again:

Just weighed it at 21 grams. My lad reckoned it should weigh about 28 grams but that was just taking some generic wax weight off the net and applying to the volume he calculated in Fusion. Tbh 21 grams filled the mould well. Currently melting 35 grams to be sure.

The dial on this Pro-Wax 100 melter is a bit hit and miss. Turn the dial up and it'll sometimes lower the temperature!

The olive oil in the background, for cleaning the wax pot after use. Found the method on YouTube. Magic!

Just weighed it at 21 grams. My lad reckoned it should weigh about 28 grams but that was just taking some generic wax weight off the net and applying to the volume he calculated in Fusion. Tbh 21 grams filled the mould well. Currently melting 35 grams to be sure.

The dial on this Pro-Wax 100 melter is a bit hit and miss. Turn the dial up and it'll sometimes lower the temperature!

The olive oil in the background, for cleaning the wax pot after use. Found the method on YouTube. Magic!

prepman

Forum Supporter

- Messages

- 2,763

- Location

- Gwynedd UK

Is the the stl freely available? If it's a private thing I understand, But if not I'll give it a go, probably in lead 1st. The horns and ears would be gulleys cast face downwards?The horns and ears in the case of the cow we're trying to do, are in effect overhangs. You don't really see that sort of feature on traditional horse brasses which is why it appealed to me to try and do it.

Happy to be told wrong but I figured investment (plaster) casting was thus the way to go. Silicone moulds would likely work but not for the temperatures involved with brass.

With the overhangs we're into almost jewellery making as I see it and then lost wax / lost PLA, lost wax being the traditional jewellery method.

I might try another wax pour into the PVA mould later. The latest PVA mould isn't perfect as aforementioned. It does seem to have some warping issues as a process but I reckon my lad can figure that with more work on the supports.

Been out of it for the best part of yesterday and today with some stomach bug and the resulting dehydration headaches. Hopefully turned the corner now. Might feel up to pottering about in a bit!

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,653

- Location

- Sevenoaks, UK

Hmmm...maybe I'm not in the mood today as seem to have lost my mojo for it. The pour wasn't as runny, because I reused the wax maybe?

I ended up using a hairdryer to encourage the wax into the fiddly bits of the mould. The back is a bit of a mess.

Still, this was always another test as the PVA mould wasn't quite right. More interested in how the letters come out.

In for a soak now.

I ended up using a hairdryer to encourage the wax into the fiddly bits of the mould. The back is a bit of a mess.

Still, this was always another test as the PVA mould wasn't quite right. More interested in how the letters come out.

In for a soak now.

Kram

Member

- Messages

- 7,885

- Location

- Sussex

I thought the first wax cow was quite good..

Wax doesnt have a high density so it could use some slight pressure to fill mould. Large syringe or a cylinder above the mould, peice of card or metal sheet over it with a filling hole to contain the excess.

Wax doesnt have a high density so it could use some slight pressure to fill mould. Large syringe or a cylinder above the mould, peice of card or metal sheet over it with a filling hole to contain the excess.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,653

- Location

- Sevenoaks, UK

I thought the first wax cow was quite good..

The letters had poor definition unfortunately and there were bits missing at the sides.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,653

- Location

- Sevenoaks, UK

Is the the stl freely available? If it's a private thing I understand, But if not I'll give it a go, probably in lead 1st. The horns and ears would be gulleys cast face downwards?

Private? Well it's unique and a fair bit of work's gone into it along with countless pints!

What were you thinking, to try in sand? Has to be brass, lead, ali, bronze are missing the point.

prepman

Forum Supporter

- Messages

- 2,763

- Location

- Gwynedd UK

It wasn't as a finished product just to see the issues with casting. I'll knock something up to tryPrivate? Well it's unique and a fair bit of work's gone into it along with countless pints!

What were you thinking, to try in sand? Has to be brass, lead, ali, bronze are missing the point.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,653

- Location

- Sevenoaks, UK

I've rushed the soaking of this a bit today as I'm not going to use the wax model. Been running it under the hot tap which has caused the wax to deform a tad in flatness but not lost any detail.

However...the letters are much more defined. The little "islands" within the "A" and "R" aren't particularly prominent I don't think.

My lad's going to re-jig the mould design now so that the loop at the top doesn't bow during printing. Also going to make those little squares at the side a bit smaller as the edges are too thin.

However...the letters are much more defined. The little "islands" within the "A" and "R" aren't particularly prominent I don't think.

My lad's going to re-jig the mould design now so that the loop at the top doesn't bow during printing. Also going to make those little squares at the side a bit smaller as the edges are too thin.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,653

- Location

- Sevenoaks, UK

Might have spoken too soon, the middle bits of the A & the R are in fact seemingly there, albeit a tad low. Maybe making them deeper, so they project slightly from the face of the final wax will work, then just need minimal taking down with a Dremel.

Kram

Member

- Messages

- 7,885

- Location

- Sussex

I thought Id have a play with the wax stuff, ordered one of these pots for tomorrow, 4 quid voucher makes it £16. Wonder if the wax beads are any good for nose hair?

I see amazon are now offering 1pm delivery! Hope thats an option every day and not just because its a Sunday.

I see amazon are now offering 1pm delivery! Hope thats an option every day and not just because its a Sunday.

Now wait for next bag...

Now wait for next bag...