greyshirtguy

Persistent Learner

- Messages

- 150

If after you've tried "everything" and it still "spatters" and, based on the knowledge that the welder used to "work much better" but has recently started spattering lots more...

That kinda suggests a step change - perhaps a sudden failure of a component.

I wonder if your output inductor (choke) has shorted??? (it's perhaps something worth checking in the end)

Where fitted they help to stabilise the current see: Inductor related post

Inductors have been known to fail - they usually short somewhere in the windings which would lead to a drop in inductance and perhaps lots more spatter....

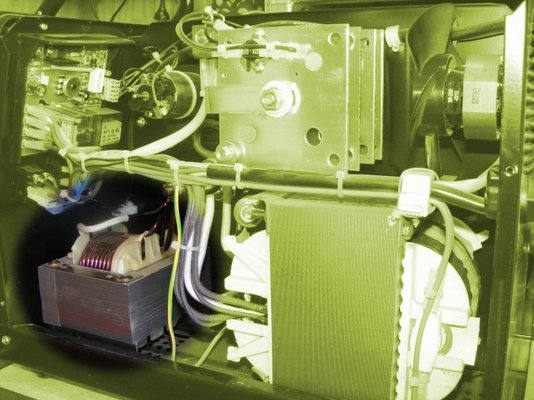

You could open the box and take a peek at it - which would reveal if there were any failure (burn-out etc) visible on the outside of it. Mind you, even if it looked ok on the outside, it is possible to have shorted in the layers of windings below.

Having said all of that....it may be just fine too!

I don't know of any easy method to test them without a special meter.

(perhaps trying a weld without it in the ciruit to see if it is contributing much difference to the performance of the weld? Although, now that I think about it - that is probably bad advice given the chances of damaging the ciruit during the re-wireing of it)

(disclaimer: dont' even open the box if you unsure about dangerously high voltage electronics)

That kinda suggests a step change - perhaps a sudden failure of a component.

I wonder if your output inductor (choke) has shorted??? (it's perhaps something worth checking in the end)

Where fitted they help to stabilise the current see: Inductor related post

Inductors have been known to fail - they usually short somewhere in the windings which would lead to a drop in inductance and perhaps lots more spatter....

You could open the box and take a peek at it - which would reveal if there were any failure (burn-out etc) visible on the outside of it. Mind you, even if it looked ok on the outside, it is possible to have shorted in the layers of windings below.

Having said all of that....it may be just fine too!

I don't know of any easy method to test them without a special meter.

(perhaps trying a weld without it in the ciruit to see if it is contributing much difference to the performance of the weld? Although, now that I think about it - that is probably bad advice given the chances of damaging the ciruit during the re-wireing of it)

(disclaimer: dont' even open the box if you unsure about dangerously high voltage electronics)