You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

my mk5 cortina estate

- Thread starter ian f

- Start date

I've got to try and sort.out this …

On my mk5 Cortina Estate.

I have managed to 'pull' most of it out, back into shape, not quite finished yet though.

The end of the front panel will have to be replaced … I'm going to have a go at fabricating the piece needed myself, if it comes out Cra...err - rubbish (swear filter, I almost forgot. Lol), I'll get someone who has experience to do it for me, but I have to try or I'll never learn/know if I can do it.

It should be a 'walk in the park' compared to some of your fabrication work.

Aaron.

On my mk5 Cortina Estate.

I have managed to 'pull' most of it out, back into shape, not quite finished yet though.

The end of the front panel will have to be replaced … I'm going to have a go at fabricating the piece needed myself, if it comes out Cra...err - rubbish (swear filter, I almost forgot. Lol), I'll get someone who has experience to do it for me, but I have to try or I'll never learn/know if I can do it.

It should be a 'walk in the park' compared to some of your fabrication work.

Aaron.

jpmillermatic

Member

- Messages

- 1,094

good progress!

JP

JP

hi all been having trouble with my welder lately (sip

been having trouble with my welder lately (sip ) but seems back to normal now thanks to a new relay on the pcb did some test runs to confirm

) but seems back to normal now thanks to a new relay on the pcb did some test runs to confirm

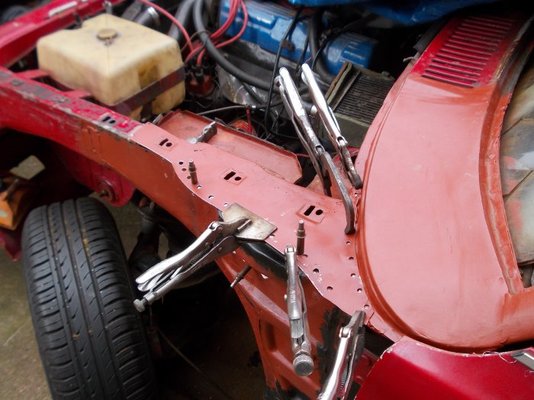

so back on the car chassis rail under the brake servo

so back on the car chassis rail under the brake servo made the new piece to enable butt welding

made the new piece to enable butt welding and welded

and welded

and roughly ground back will finish the grinding when i paint the engine bay. thanks for looking

and roughly ground back will finish the grinding when i paint the engine bay. thanks for looking

been having trouble with my welder lately (sip

been having trouble with my welder lately (sip ) but seems back to normal now thanks to a new relay on the pcb did some test runs to confirm

) but seems back to normal now thanks to a new relay on the pcb did some test runs to confirm

so back on the car chassis rail under the brake servo

so back on the car chassis rail under the brake servo made the new piece to enable butt welding

made the new piece to enable butt welding and welded

and welded

and roughly ground back will finish the grinding when i paint the engine bay. thanks for looking

and roughly ground back will finish the grinding when i paint the engine bay. thanks for looking

marlinspike

Member

- Messages

- 1,953

Great work, Ian. Very inspiring. Looking forward to more updates. I have loads to fo on my car, but fibd ut hard ti get motivated when it's cold and wet outside.

nice weather today with not much wind so decided to repair the rot behind the heater box trimmed a patch for butt welding

trimmed a patch for butt welding and painted the inside

and painted the inside then lined up and a few tack welds added while adjustments were made

then lined up and a few tack welds added while adjustments were made then fully welded a bit at a time to avoid too much heat buildup

then fully welded a bit at a time to avoid too much heat buildup then ground back roughly just enough to paint it as the neighbours and their kids were in the garden and didn't want to disturb them too much

then ground back roughly just enough to paint it as the neighbours and their kids were in the garden and didn't want to disturb them too much followed by a coat of bondaprimer to hold it 'til the respray

followed by a coat of bondaprimer to hold it 'til the respray

trimmed a patch for butt welding

trimmed a patch for butt welding and painted the inside

and painted the inside then lined up and a few tack welds added while adjustments were made

then lined up and a few tack welds added while adjustments were made then fully welded a bit at a time to avoid too much heat buildup

then fully welded a bit at a time to avoid too much heat buildup then ground back roughly just enough to paint it as the neighbours and their kids were in the garden and didn't want to disturb them too much

then ground back roughly just enough to paint it as the neighbours and their kids were in the garden and didn't want to disturb them too much followed by a coat of bondaprimer to hold it 'til the respray

followed by a coat of bondaprimer to hold it 'til the respray

marlinspike

Member

- Messages

- 1,953

That is some very impressive welding and fabrication, Ian. I am having trouble getting motivated to work on my car, but your thread inspires me to get stuck in.

jpmillermatic

Member

- Messages

- 1,094

glad your still plugging away on this project...looks great!

JP

JP

nice weather today so done a bit more,panel below drivers side rear window got a sheet of 48"x6"x1/2" 1mm steel i like this because i have 1 less fold to do (i'm that lazy!)

got a sheet of 48"x6"x1/2" 1mm steel i like this because i have 1 less fold to do (i'm that lazy!) made a template

made a template did the first bend

did the first bend check against template

check against template then hammered in the bottom fold

then hammered in the bottom fold checking for fit

checking for fit

hammering in the tabs

hammering in the tabs  another test fit

another test fit front edge formed

front edge formed

not too bad, shame it wont be seen

not too bad, shame it wont be seen

got a sheet of 48"x6"x1/2" 1mm steel i like this because i have 1 less fold to do (i'm that lazy!)

got a sheet of 48"x6"x1/2" 1mm steel i like this because i have 1 less fold to do (i'm that lazy!) made a template

made a template did the first bend

did the first bend check against template

check against template then hammered in the bottom fold

then hammered in the bottom fold checking for fit

checking for fit

hammering in the tabs

hammering in the tabs  another test fit

another test fit front edge formed

front edge formed

not too bad, shame it wont be seen

not too bad, shame it wont be seen

mike 109444

Member

- Messages

- 4,742

"shame it won't be seen" Yes BUT you know it's there

rustyoldford

Member

- Messages

- 42

Top work there i do love fords, your work is inspirational.

Bet that its very difficult to get hold of any panels for your car these days i may start stocking up on sierra panels now as their cheap lol after seeing how much cortina stuff goes for !

Rustyoldford

Bet that its very difficult to get hold of any panels for your car these days i may start stocking up on sierra panels now as their cheap lol after seeing how much cortina stuff goes for !

Rustyoldford

managed to get the panel welded in last week but forgot to post top edge welded a little at a time

top edge welded a little at a time until complete

until complete and inside done as well

and inside done as well so todays work was on the roof pillar, too scabby to clean up

so todays work was on the roof pillar, too scabby to clean up so cut out

so cut out repair panel made

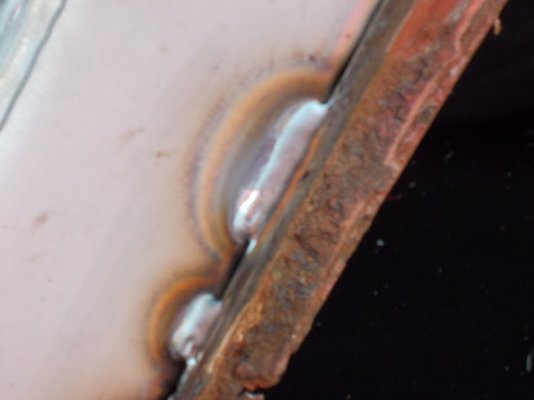

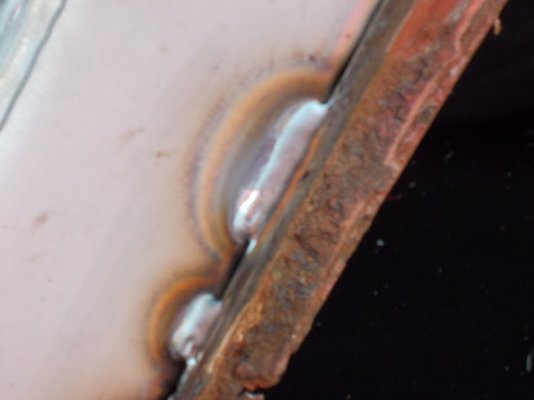

repair panel made  started welding

started welding  bit at a time then allow to cool

bit at a time then allow to cool closeup

closeup welding completed and wire brushed

welding completed and wire brushed and a couple of close up shots hope you find my welds acceptable

and a couple of close up shots hope you find my welds acceptable

top edge welded a little at a time

top edge welded a little at a time until complete

until complete and inside done as well

and inside done as well so todays work was on the roof pillar, too scabby to clean up

so todays work was on the roof pillar, too scabby to clean up so cut out

so cut out repair panel made

repair panel made  started welding

started welding  bit at a time then allow to cool

bit at a time then allow to cool closeup

closeup welding completed and wire brushed

welding completed and wire brushed and a couple of close up shots hope you find my welds acceptable

and a couple of close up shots hope you find my welds acceptable

not conducive to working on cars especially this time of the year. Still doing fabulous work, I am really enjoying following your progress.

not conducive to working on cars especially this time of the year. Still doing fabulous work, I am really enjoying following your progress.