You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

my mk5 cortina estate

- Thread starter ian f

- Start date

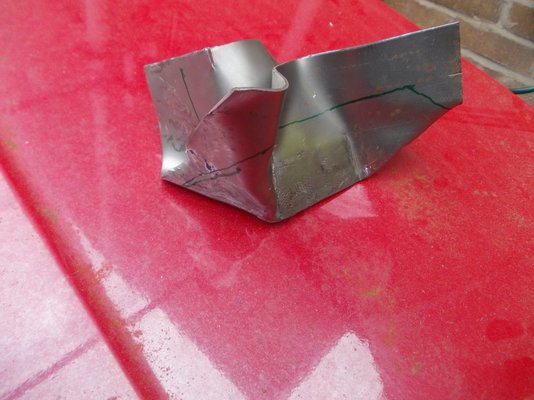

got the inner valance made and welded in yesterday while we had some "decent" weather. my mate is going to help me build a carport after christmas but until then i'm at the mercy of the weather, my days of welding in the rain are over i've decided!

before anybody says it i'm going to try and reprofile the swages on the left to make them the same length as the others

before anybody says it i'm going to try and reprofile the swages on the left to make them the same length as the others

before anybody says it i'm going to try and reprofile the swages on the left to make them the same length as the others

before anybody says it i'm going to try and reprofile the swages on the left to make them the same length as the others

God mode restorations

Member

- Messages

- 8,096

- Location

- uk colchester

Hi...

nice to see an old school ford..and superbly made panels..great stuff...

nice to see an old school ford..and superbly made panels..great stuff...

but before going any further on that piece i need to make a new petrol tank mount which is a little crusty

which is a little crusty so cut a new piece of 1.5mm steel and folded it over

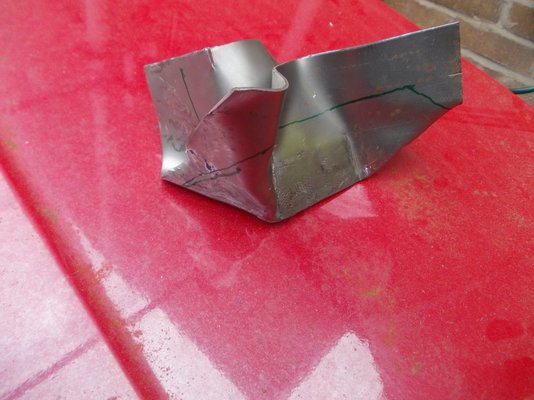

so cut a new piece of 1.5mm steel and folded it over clamp in the vice and open the ends up a little

clamp in the vice and open the ends up a little then smack the living crap out of it until it takes the correct shape

then smack the living crap out of it until it takes the correct shape ready for trimming

ready for trimming then weld on the extra pieces that attach it to the chassis

then weld on the extra pieces that attach it to the chassis

which is a little crusty

which is a little crusty so cut a new piece of 1.5mm steel and folded it over

so cut a new piece of 1.5mm steel and folded it over clamp in the vice and open the ends up a little

clamp in the vice and open the ends up a little then smack the living crap out of it until it takes the correct shape

then smack the living crap out of it until it takes the correct shape ready for trimming

ready for trimming then weld on the extra pieces that attach it to the chassis

then weld on the extra pieces that attach it to the chassis

had a good go at the car last week. i thought i'd posted it here but obviously didn't first piece the vertical part of the boot floor which has to go on before the chassis repair

first piece the vertical part of the boot floor which has to go on before the chassis repair

then welded in sorry it looks a bit rough i had the wire speed a little high

then welded in sorry it looks a bit rough i had the wire speed a little high

then the "boot floor bottom" was welded in

then the "boot floor bottom" was welded in

i should mention the chassis repair which is the part where the petrol tank mount welds to, it was a bit thin on two sides so i cut them out and welded new pieces in sounds easy but was a right pain but was made easier having bought a evolution powerfile to get in to clean up the area

i should mention the chassis repair which is the part where the petrol tank mount welds to, it was a bit thin on two sides so i cut them out and welded new pieces in sounds easy but was a right pain but was made easier having bought a evolution powerfile to get in to clean up the area

side piece on

side piece on

then the bottom next job should be welding the tank mount on

then the bottom next job should be welding the tank mount on

first piece the vertical part of the boot floor which has to go on before the chassis repair

first piece the vertical part of the boot floor which has to go on before the chassis repair

steveo3002

Member

- Messages

- 7,952

good stuff , i like the panels you are making

could you post more pics of how you make the panels please

could you post more pics of how you make the panels please

i knew i'd forgot something the same time i did all the above i also closed off the cut outs that i did to gain access to the lower boot floor i had to do this as it was covered in waxoil but i suspect the panels were rusting away when i injected it many years ago. so first piece tacked in

the same time i did all the above i also closed off the cut outs that i did to gain access to the lower boot floor i had to do this as it was covered in waxoil but i suspect the panels were rusting away when i injected it many years ago. so first piece tacked in

then number 2

then number 2

and the last

and the last

then go round doing a couple of spots until filled in

then go round doing a couple of spots until filled in

then clened off with a flap disc and the powerfile, not perfect but good enough

then clened off with a flap disc and the powerfile, not perfect but good enough

the same time i did all the above i also closed off the cut outs that i did to gain access to the lower boot floor i had to do this as it was covered in waxoil but i suspect the panels were rusting away when i injected it many years ago. so first piece tacked in

the same time i did all the above i also closed off the cut outs that i did to gain access to the lower boot floor i had to do this as it was covered in waxoil but i suspect the panels were rusting away when i injected it many years ago. so first piece tacked in

marlinspike

Member

- Messages

- 2,198

Nice work. I don't know how you manage to get those short runs without blowing through. Is the metal pretty thick in Cortina boots?

hi, i'll try and take more picsgood stuff , i like the panels you are making

could you post more pics of how you make the panels please

not thick metal at all, 20 gauge or 1mm i reckon plus i cleaned up the edges with the powerfile so probably a bit thinner it's just a case of expecting it to blow through and stopping before it doesNice work. I don't know how you manage to get those short runs without blowing through. Is the metal pretty thick in Cortina boots?

must admit i got it wrong a few times though

must admit i got it wrong a few times though forgot to add the final pic yesterday sorry

forgot to add the final pic yesterday sorry

more rust i swear one day i'll get this thing finished. so, the spare wheel well seemed pretty solid

i swear one day i'll get this thing finished. so, the spare wheel well seemed pretty solid

but when i was doing the petrol tank mount i noticed it was very thin in many places, if i dont sort it now i'm going to have to do it in a year or so

but when i was doing the petrol tank mount i noticed it was very thin in many places, if i dont sort it now i'm going to have to do it in a year or so

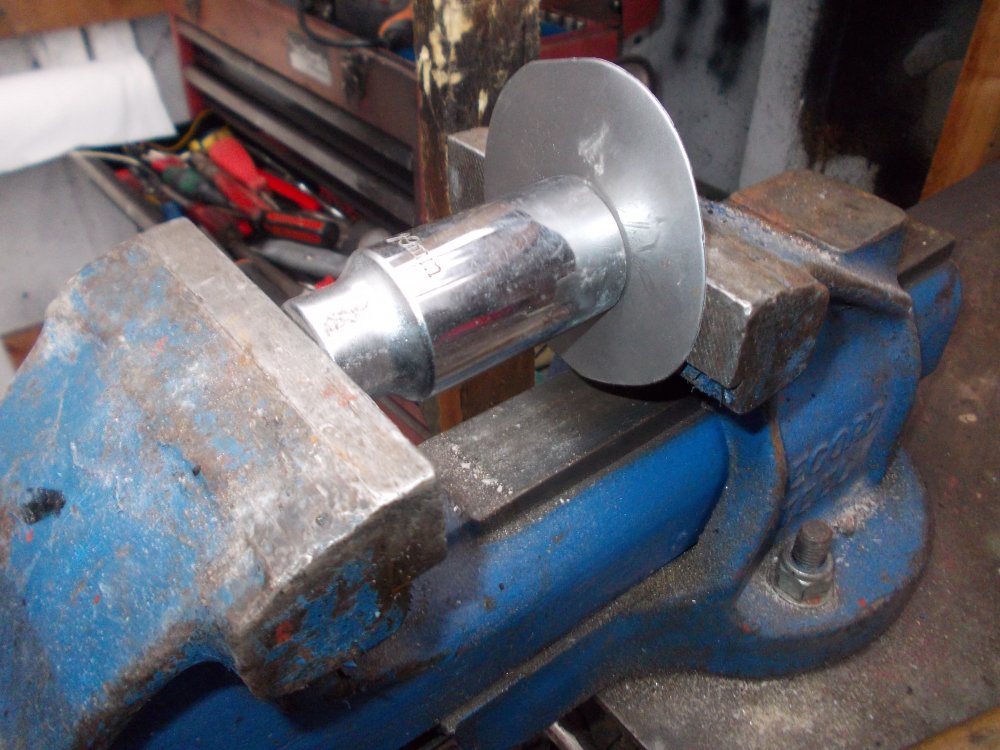

so using the spare wheel i cut out a blank

so using the spare wheel i cut out a blank

which i then started to hollow into a sandbag

which i then started to hollow into a sandbag

then added the pressings for the drain plug holes

then added the pressings for the drain plug holes

paint and spare wheel bracket removed to enable copying of swages in floor

paint and spare wheel bracket removed to enable copying of swages in floor

then added to new panel by chasing into sandbag with a rounded flat chisel

then added to new panel by chasing into sandbag with a rounded flat chisel

then edge hollowed into bag to give some curvature

then edge hollowed into bag to give some curvature

view from underneath, doesn't need to be perfect

view from underneath, doesn't need to be perfect

then another trial fit

then another trial fit

i swear one day i'll get this thing finished. so, the spare wheel well seemed pretty solid

i swear one day i'll get this thing finished. so, the spare wheel well seemed pretty solidtime to make the drain hole plugs

clamp socket and blank in the vice

clamp socket and blank in the vice

and smack over socket with plastic hammer

and smack over socket with plastic hammer

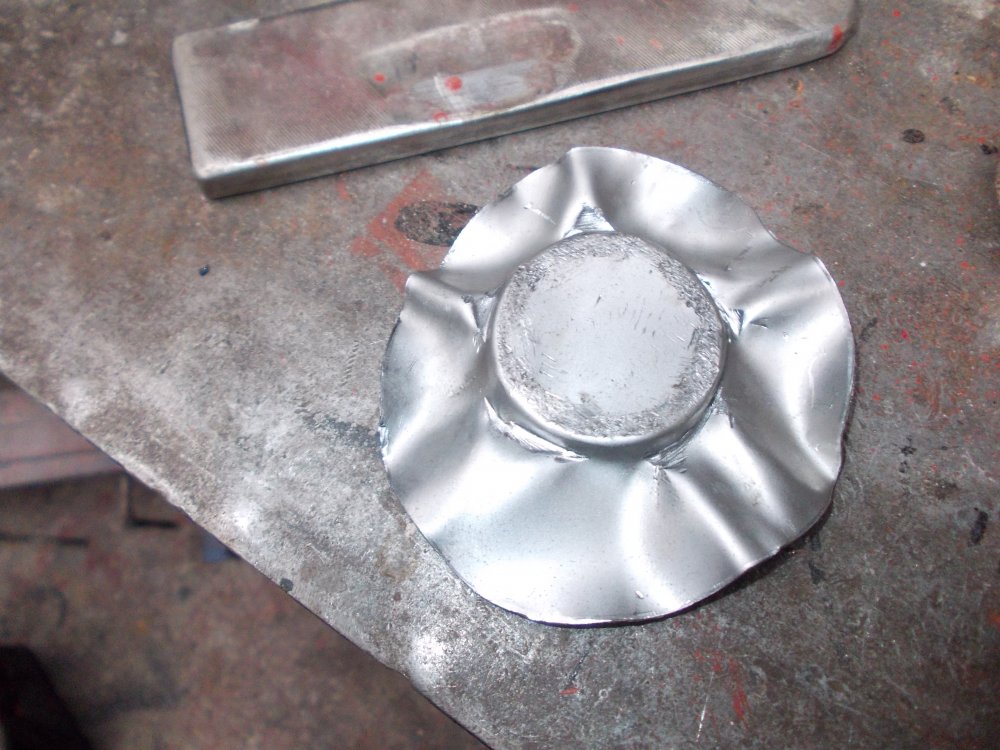

then flatten out where required with flat bar to make step

then flatten out where required with flat bar to make step

then open out with small hammer

then open out with small hammer

leaving this which needs dressing flat

leaving this which needs dressing flat

like so

like so

then trim edge

then trim edge

normspanners

Member

- Messages

- 8,842

This is not a ford cortina

it should be renamed an IAN F CORTINA.

coz there is more of your panels than fords.

Your not from India are you?

it should be renamed an IAN F CORTINA.

coz there is more of your panels than fords.

Your not from India are you?

then after all that i realized the "step" in the middle of the panel isn't as pronounced as i thought more of a gentle pressing hope that makes sense

hope that makes sense

so had to dress it down with a plastic hammer and block of wood. then holes cut out for the drain plugs

so had to dress it down with a plastic hammer and block of wood. then holes cut out for the drain plugs

and finally trial fit with plugs

and finally trial fit with plugs

laid in position

laid in position

hope that makes sense

hope that makes sense

more or less finished so i can now concentrate on getting the cortina done

more or less finished so i can now concentrate on getting the cortina done