- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My new Harrison lathe

- Thread starter God mode restorations

- Start date

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

That is what I will do. Need to get a couple made for the spindle locking collars.I was going to suggest that - drill a peg hole in the spindle - it will never notice it - and make a peg spanner. Perhaps you could get a peg spanner laser or plasma-cut locally?

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

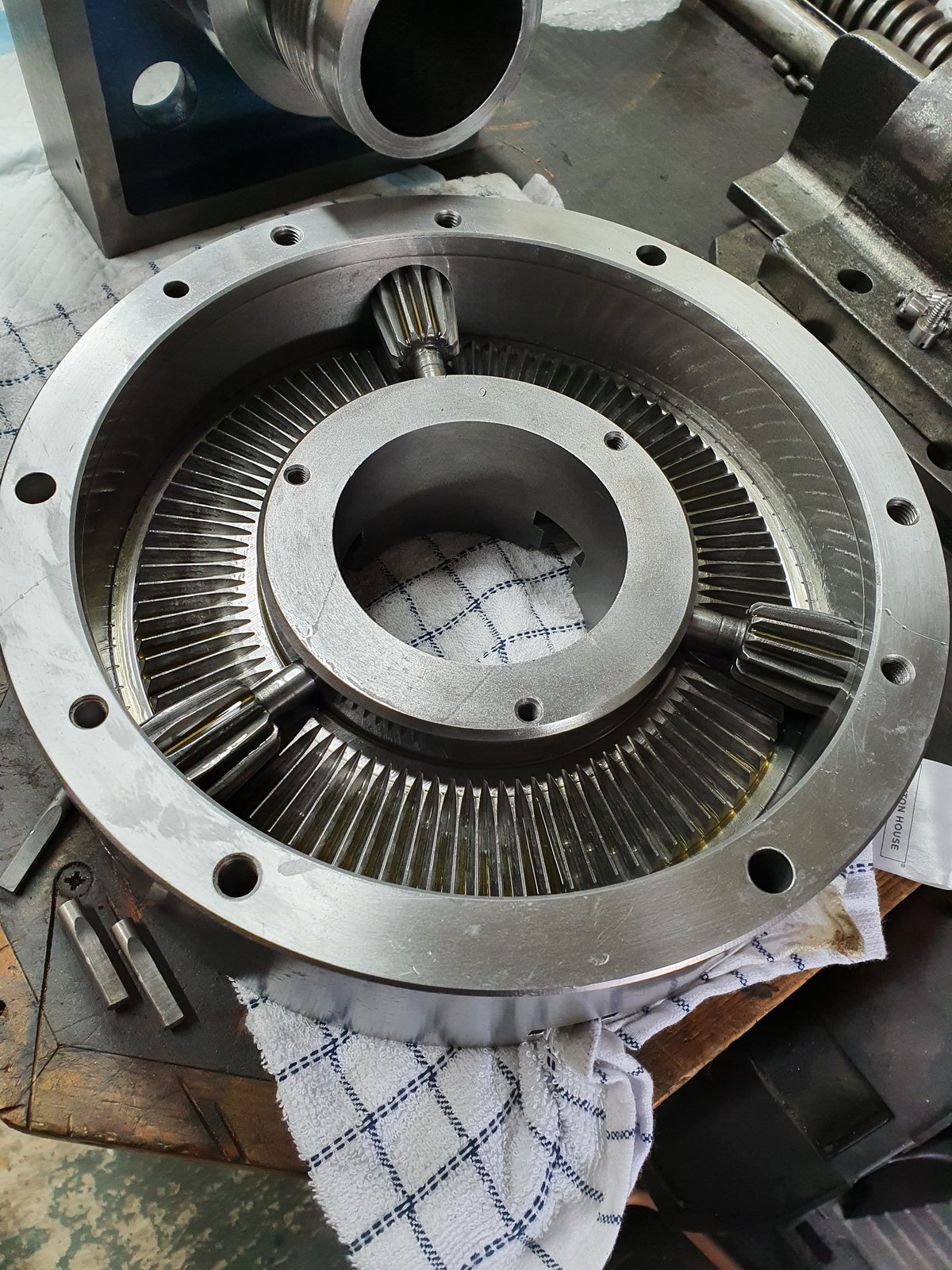

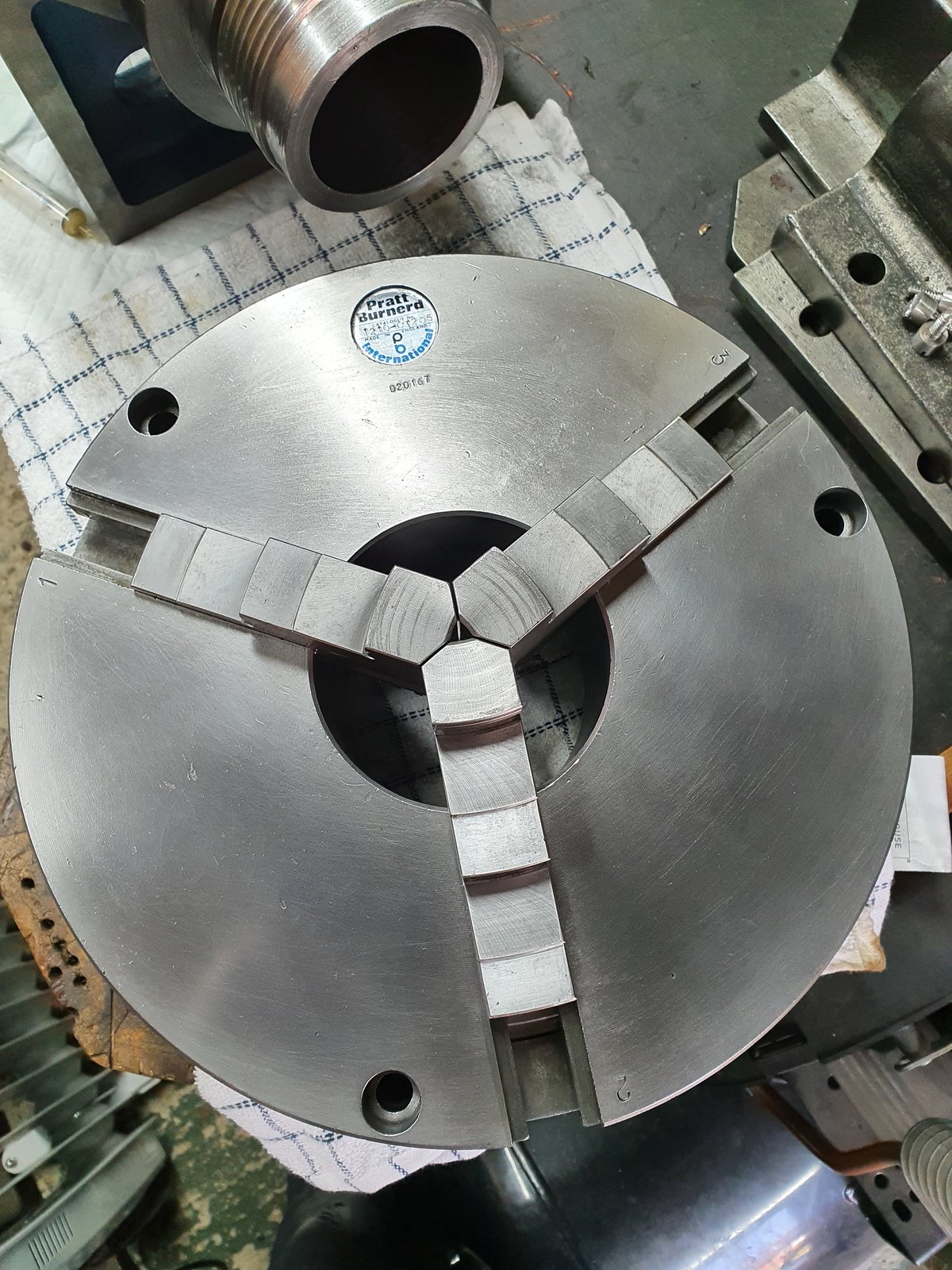

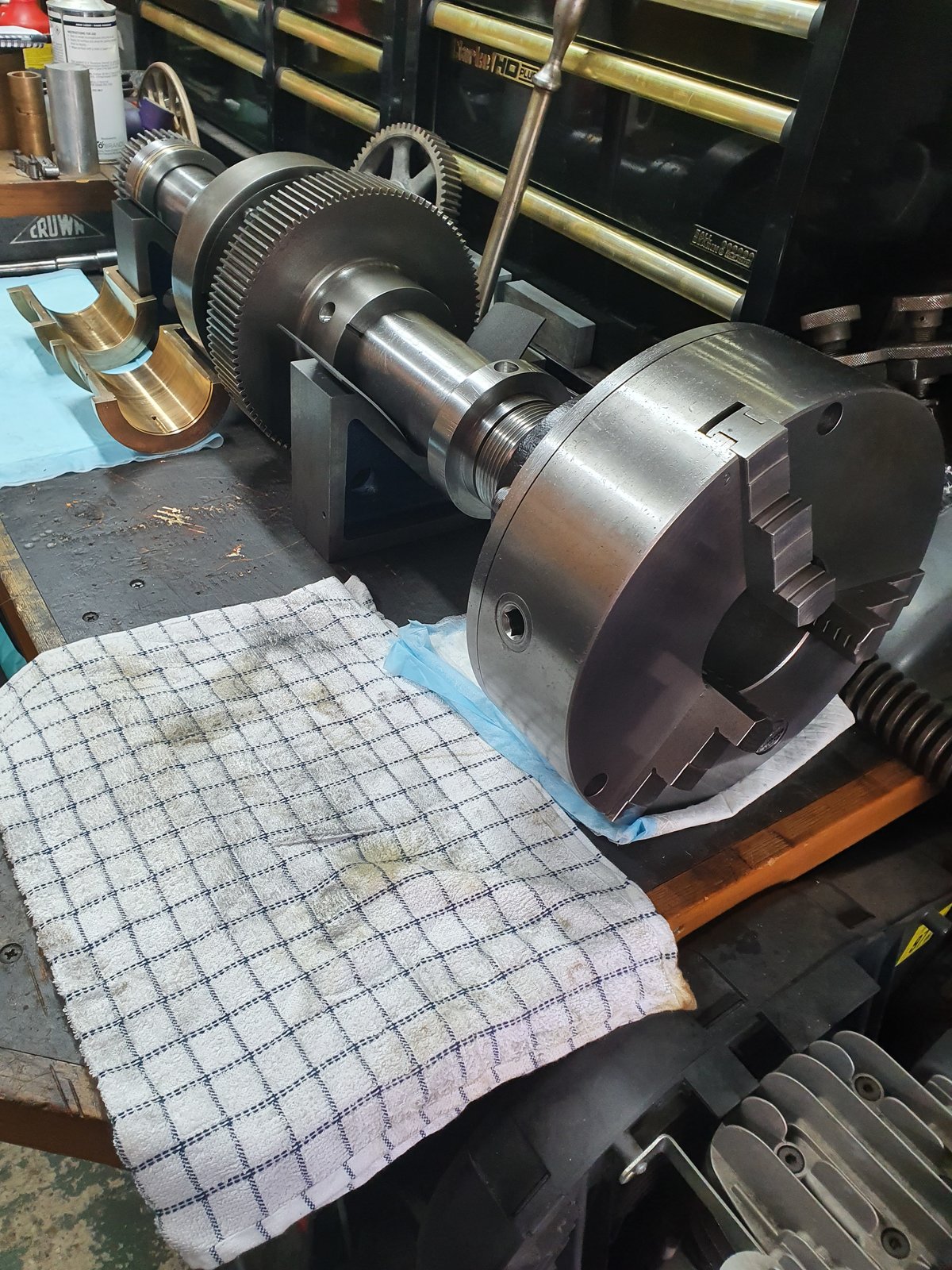

Three jaw complete. All parts spotlessly clean and oiled before assembly. I shant show all the photos as there is a lot of em. Works beautifully as should....time consuming and hard graft....four jaw next....but not just yet....do I want to do more chucks or for others....not partially.....unless ya got a pocket full of wedge ...

Spark plug

Member

- Messages

- 4,062

- Location

- Durham, England

Three jaw complete. All parts spotlessly clean and oiled before assembly. I shant show all the photos as there is a lot of em. Works beautifully as should....time consuming and hard graft....four jaw next....but not just yet....do I want to do more chucks or for others....not partially.....unless ya got a pocket full of wedge ...View attachment 222637 View attachment 222638 View attachment 222639 View attachment 222640 View attachment 222641 View attachment 222642

It would have been interesting to know the runout before and after but I don’t suppose you could have measured this with the spindle on the bench.

I must get round to sorting my 3 jaw, although i think the gorilla’s have been swinging on it.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

I will find out when I put the lot back together...I sure there will be fettling to doIt would have been interesting to know the runout before and after but I don’t suppose you could have measured this with the spindle on the bench.

I must get round to sorting my 3 jaw, although i think the gorilla’s have been swinging on it.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

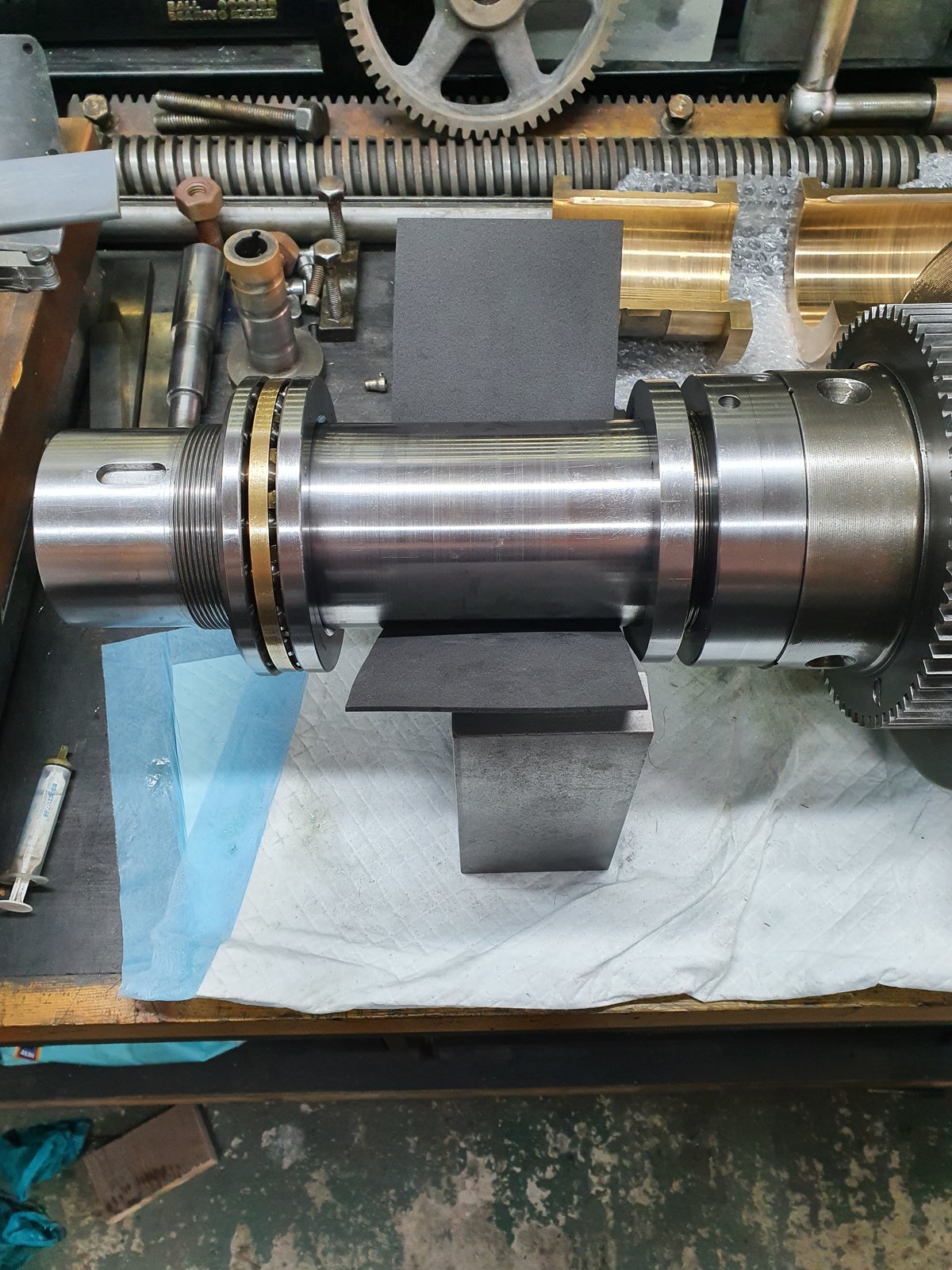

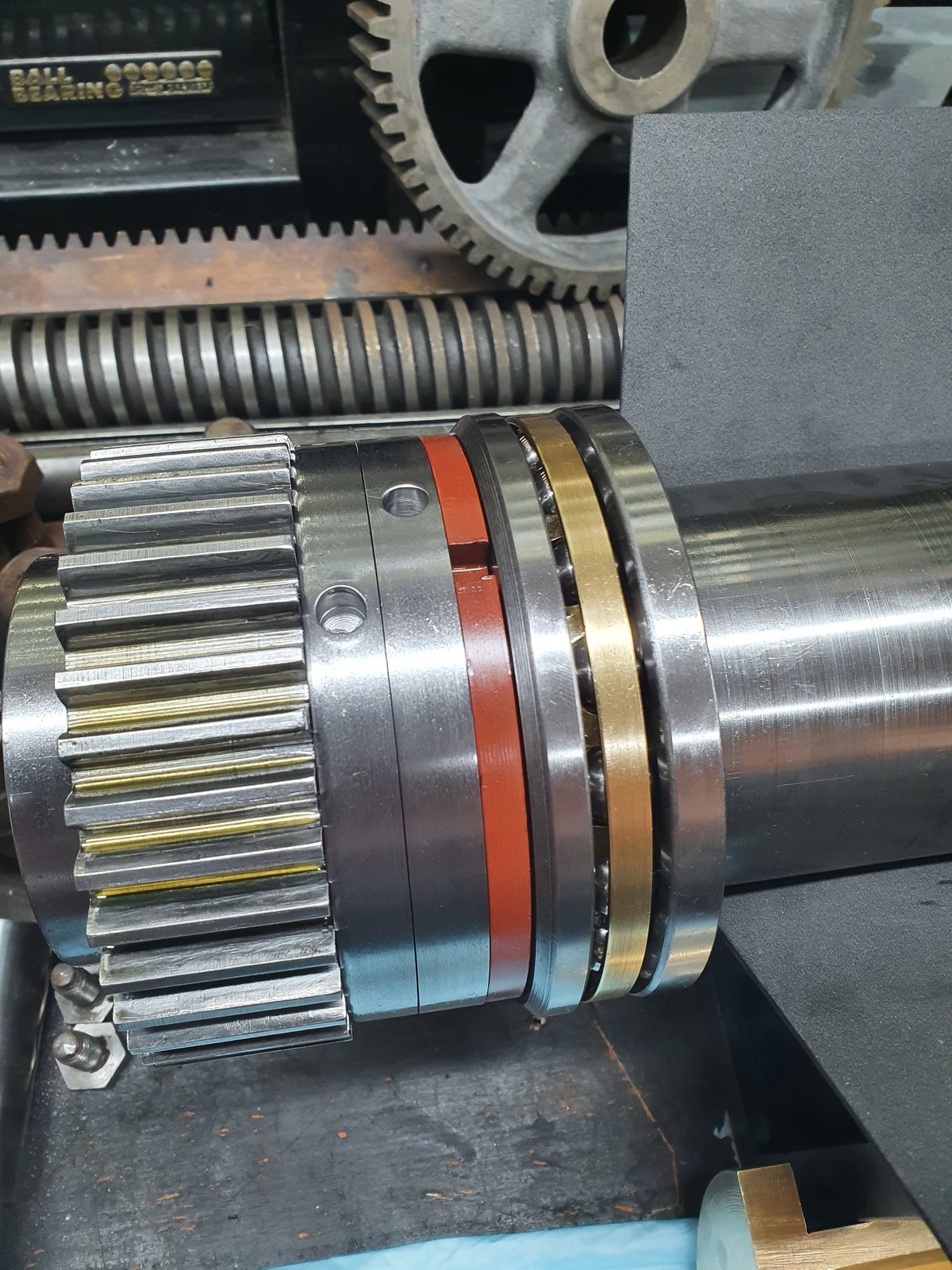

Re drilled the holes on the locking collars and started assembling....and that's as far as it goes today....

Agroshield

Member

- Messages

- 5,662

Three jaw complete

Would it pay to put a gasket between the first backplate and the chuck body to fill the gap? Look at the swarf that was there when you dismantled it. Lightly glue it in place with RTV silicone.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Its possible yes. Depending on the gap size. I have got to take a couple of bolts out for thread measuring so I will give it a look .Would it pay to put a gasket between the first backplate and the chuck body to fill the gap? Look at the swarf that was there when you dismantled it. Lightly glue it in place with RTV silicone.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Done.....thank f.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

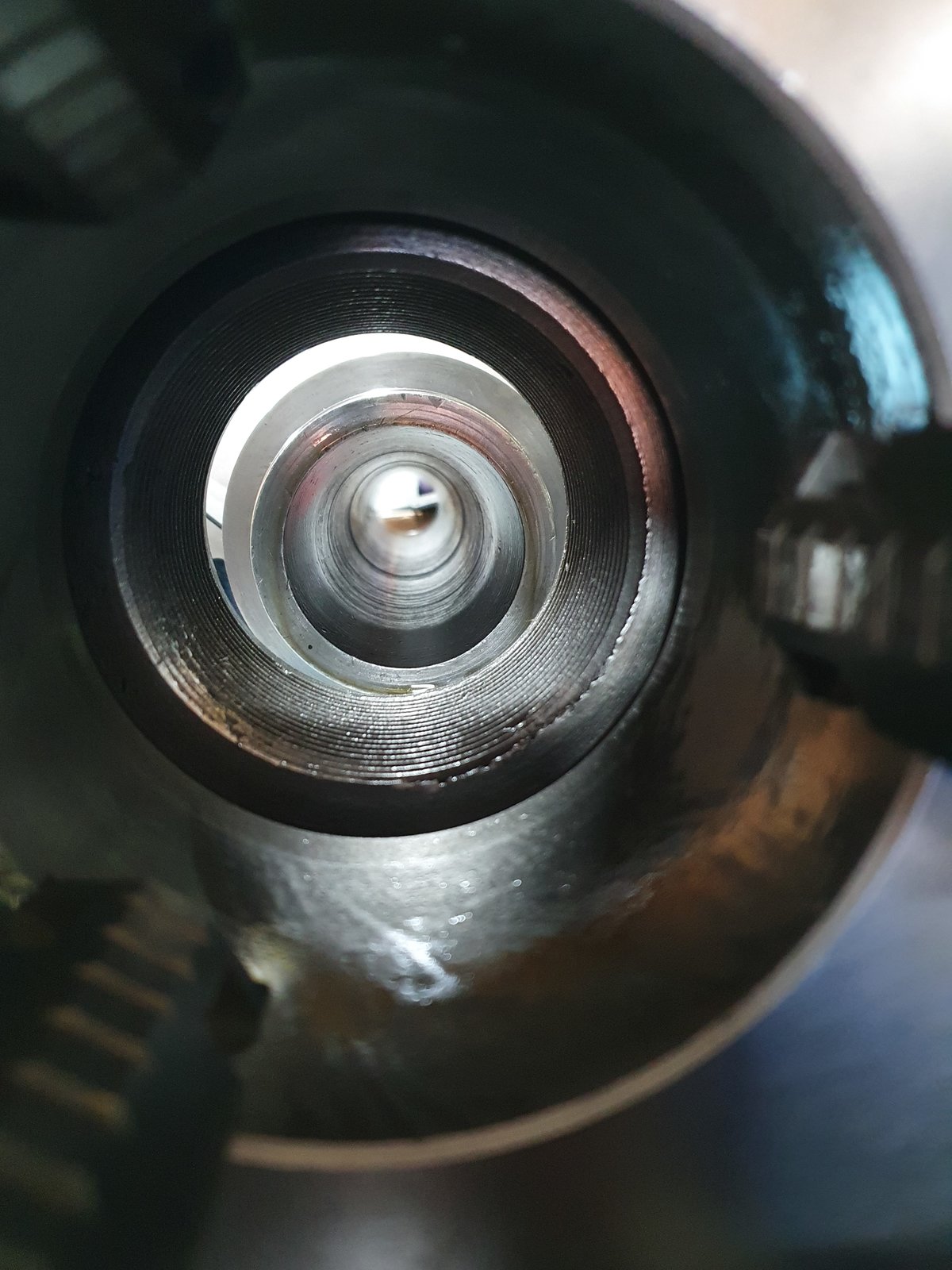

Just remembered to oil inside the spindle. A big lump of rag tied to the jack handle and covered in oil and stick it down the spindle. Sorted.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Next on the list is the clutch control lever. Its bent and the taper pin is seized. I will drill the old pin out and remove the hole to the corresponding pin size. Straighten the lever....it dont stop here guys....

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Cheers brad. I am in the process of knocking up a drawing so will definitely give you a shout when I sort it.Can plasma cut you a pin or hook wrench if you need one

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Tell me about it....I will do me best with itIt looks like it's been attacked by a Gorilla.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Taper pin drilled out and removed. Handle removed from shaft. This has a serious bend in it right on the end...its taken some serious force to bend that like that....nothing I can fix.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,337

- Location

- NE London - UK

I'd turn some wood blocks

If you've got a spare piece of Ebony or Box laying around. Or maybe some well seasoned Oak?

Last edited:

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

It takes a lot of force to bend it where it is...its surprising it never cracked the handle where the key sits.