You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NBC Auto Weld 2 - inside a 50 year old MIG

- Thread starter a111r

- Start date

One has just made an appearance on Marketplace for just £60!

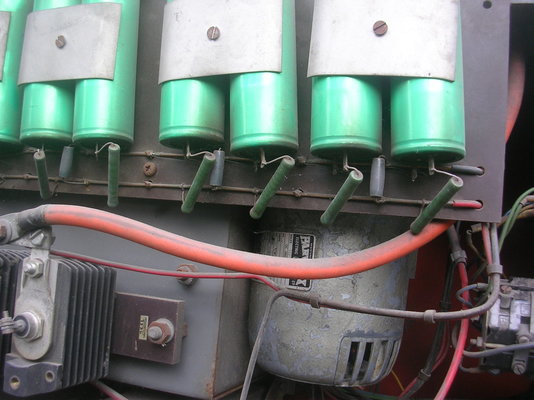

The capacitors fitted to it are 'quite small', compared to the originals.

www.facebook.com

www.facebook.com

The capacitors fitted to it are 'quite small', compared to the originals.

Log in to Facebook

Log in to Facebook to start sharing and connecting with your friends, family and people you know.

www.facebook.com

www.facebook.com

It has the original Butters torch still fitted, I think, which must be very rare? Plus, some wooden additions.

I'm surprised that it feeds wire, with all the rust present, caused by the alloy top cover being missing.

Mine also lives outside, due to the excessive mass.

I'm surprised that it feeds wire, with all the rust present, caused by the alloy top cover being missing.

Mine also lives outside, due to the excessive mass.

arther dailey

Member

- Messages

- 6,973

- Location

- England

rather ironic for a welder manufacture to use rivets !If all the relays are still in that one, it would be a good solution.... I like the way that the frame is fastened with riveted and bolted corner gusset plates, like a 20's wrought iron bridge.

PM sent.i have now scanned the entire manual and sent it to Malcolm if you send me your email address i will send it to you

With no other broken MIGs to fix, I had to have another look at this 70's dinosaur today, despite no manual or schematic appearing on here yet, or else I'd go 'Cold Turkey' (or worse, attempt do some actual MIG welding).

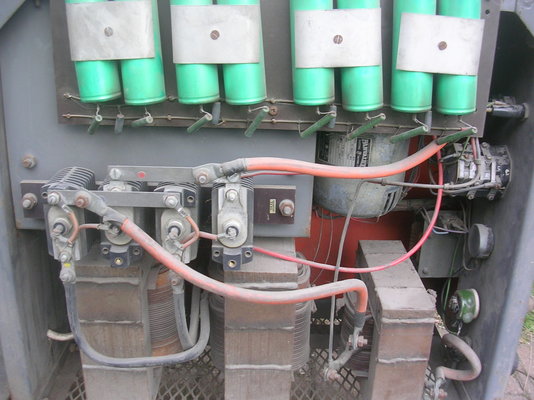

As mentioned, the contactor works and there's a valid range of OCVs are present and correct. Just no 'feed motor action'.

Ranchero also helpfully indicated that the missing relay is timer related, not motor related, so that's not a real issue here.

I did a bit more checking of the many terminal screw connections and also did some cleaning of the various bolted joint (always good to do) but with no joy.

Time to look at the big old Parvalux motor, then...

It seemed to be being fed 110 Vdc 'OK', so I dropped it. Which was not hard - it's been off a few times before, by grease monks with adjustable spanners.

The reduction gearbox was also easily removed. The casing split apart easily and (for us old, 50 plus chaps) it's basically a nice, posh Lucas dynamo.

Internally nothing looked bad or smelled burnt. The field coils have a resistance of 380 Ohms, and the armature windings are around 9 Ohms. Not sure if that's good or bad.

The brushes were both fine but the commutator was oxidised and very dark, so I cleaned it up with a grey Scotch-brite.

I did not re-assemble the motor. I'll post up some photos, before this happens next week.

As mentioned, the contactor works and there's a valid range of OCVs are present and correct. Just no 'feed motor action'.

Ranchero also helpfully indicated that the missing relay is timer related, not motor related, so that's not a real issue here.

I did a bit more checking of the many terminal screw connections and also did some cleaning of the various bolted joint (always good to do) but with no joy.

Time to look at the big old Parvalux motor, then...

It seemed to be being fed 110 Vdc 'OK', so I dropped it. Which was not hard - it's been off a few times before, by grease monks with adjustable spanners.

The reduction gearbox was also easily removed. The casing split apart easily and (for us old, 50 plus chaps) it's basically a nice, posh Lucas dynamo.

Internally nothing looked bad or smelled burnt. The field coils have a resistance of 380 Ohms, and the armature windings are around 9 Ohms. Not sure if that's good or bad.

The brushes were both fine but the commutator was oxidised and very dark, so I cleaned it up with a grey Scotch-brite.

I did not re-assemble the motor. I'll post up some photos, before this happens next week.

Will Porter

New Member

- Messages

- 10

- Location

- Wales UK

Technical arc in York list a 11 pin relay for Butters in their catalog, it might be worth giving them a call.

01904 410041

01904 410041

Thank you, Will, a good find and I may do that.

With welding voltage present but no feed motor action, I gave it a 'short circuit' using a MB36 with a worn out tip. It produced a nice, gentle blue arc.

How to test a 110 volt DC shunt wound motor with minimal equipment?

So, I'm at a bit of a quandary now what to do with it, as I don't need / want it, long term:

1. Carry on, without much idea what I'm looking for.

2. Offer it to someone to take over (hint...)

3. Scrap it (....NO !!)

4. Use the awesome massive transformers / diodes / 8 caps to build a FrankenButters, housed in a smaller case, with a smaller Euro wire feeder and a universal control PCB instead of the telephone exchange of aged wire and relays.

With welding voltage present but no feed motor action, I gave it a 'short circuit' using a MB36 with a worn out tip. It produced a nice, gentle blue arc.

How to test a 110 volt DC shunt wound motor with minimal equipment?

So, I'm at a bit of a quandary now what to do with it, as I don't need / want it, long term:

1. Carry on, without much idea what I'm looking for.

2. Offer it to someone to take over (hint...)

3. Scrap it (....NO !!)

4. Use the awesome massive transformers / diodes / 8 caps to build a FrankenButters, housed in a smaller case, with a smaller Euro wire feeder and a universal control PCB instead of the telephone exchange of aged wire and relays.

Will Porter

New Member

- Messages

- 10

- Location

- Wales UK

You could use a yellow site transformer with a rectifier on the 110v outlet to test the feed motor

I'd take the hint but live too far away and being a proud Yorkshireman, I'd have to demand that you paid postage and also grease my palms (which I would take off my wallet for a few seconds) for taking it off your handsThank you, Will, a good find and I may do that.

With welding voltage present but no feed motor action, I gave it a 'short circuit' using a MB36 with a worn out tip. It produced a nice, gentle blue arc.

How to test a 110 volt DC shunt wound motor with minimal equipment?

So, I'm at a bit of a quandary now what to do with it, as I don't need / want it, long term:

1. Carry on, without much idea what I'm looking for.

2. Offer it to someone to take over (hint...)

3. Scrap it (....NO !!)

4. Use the awesome massive transformers / diodes / 8 caps to build a FrankenButters, housed in a smaller case, with a smaller Euro wire feeder and a universal control PCB instead of the telephone exchange of aged wire and relays.

Some good suggestions, thanks chaps. I went to the Doctor.I'd take the hint but live too far away and being a proud Yorkshireman, I'd have to demand that you paid postage and also grease my palms (which I would take off my wallet for a few seconds) for taking it off your hands

"Choose sitting on that couch watching mind-numbing spirit-crushing game shows, stuffing fecking junk food into your mouth. Choose rotting away at the end of it all, pishing your last in a miserable home".

A surprising response. As I didn't really want an escalation to Tramadol and my young GP must be the only one who drives a BMW E30..???

I've discovered a couple of earlier Autoweld threads, including a "circuit diagram":

NBC Autoweld2 control transformer burned out, can anyone help?

I have an NBC (Butters) AutoWeld2 which is God knows how old (or it may be older than God, I'm not sure). Anyway, the control transformer (wot makes things click) has burned out - the main transformers are still fine. I reckon it should be easy enough to pop a new universal transformer in...

www.mig-welding.co.uk

Feed roller(s) for NBC Autoweld 2

I'm looking for a new pair of 0.8mm feed wheels for my (very) old NBC Autoweld 2. I have no idea if they're a universal part or machine-specific, can anyone shed any light or sell me a set?

www.mig-welding.co.uk