- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me - Colchester Triumph

- Thread starter Lewis_RX8

- Start date

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

You got a very good deal there mate..rare these days to find such a score

Defiantly, When I was speaking to the seller he actually sold it for £1100 before with a lot of bids and interested messages etc however the buyer looked at it decided it was too hard to transport to pull out and the second highest bidder did the same so surprising I was the only bid this time.

Bit of history on the machine as well , He bought it 20 years ago off a RAF base auction for about £1700 at the time with all accessories etc. Me thinks that's a good thing as not production work all day everyday wearing out the ways doing parts over and over again.

Also very interesting bloke in general self employers hydraulics engineer and converted borers and some of them made on the lathe that cut the channel tunnel so the lathe has certainly made its mark and helped millions travel through Europe lol

roofman

Purveyor of fine English buckets and mops

- Messages

- 12,352

- Location

- North West with water on 3 sides

A keeper that girl is...keep us all updated on the build upDefiantly, When I was speaking to the seller he actually sold it for £1100 before with a lot of bids and interested messages etc however the buyer looked at it decided it was too hard to transport to pull out and the second highest bidder did the same so surprising I was the only bid this time.

Bit of history on the machine as well , He bought it 20 years ago off a RAF base auction for about £1700 at the time with all accessories etc. Me thinks that's a good thing as not production work all day everyday wearing out the ways doing parts over and over again.

Also very interesting bloke in general self employers hydraulics engineer and converted borers and some of them made on the lathe that cut the channel tunnel so the lathe has certainly made its mark and helped millions travel through Europe lol

Should be fun aligning everything

A keeper that girl is...keep us all updated on the build up

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Should be fun aligning everything

Going to have to have some patience with this I think

roofman

Purveyor of fine English buckets and mops

- Messages

- 12,352

- Location

- North West with water on 3 sides

Took the head off a lathe once (3 lathes ago) and it took me a good couple weeks after i put the head back on to get the whole lathe dialed in again. My advice would be get the base set and leave to settle down for a day, then put the head on and leave that to settle in before you start tightening bolts and checking center heights and turning between the centers.Should be fun aligning everything

Pete.

Member

- Messages

- 14,574

- Location

- Kent, UK

It's apart so it doesn't much matter now. It looks like it might be an adjustable headstock type but I can't tell from the pics. If it is then:

Get the bed into position and fixed down. Use a sensitive level to get the bed straight

Clean the headstock and bed and fit it up. Make test cuts to adjest the headstock for parallel cutting

Adjust the tailstock height and set-over for parallel turning between centres.

Get the bed into position and fixed down. Use a sensitive level to get the bed straight

Clean the headstock and bed and fit it up. Make test cuts to adjest the headstock for parallel cutting

Adjust the tailstock height and set-over for parallel turning between centres.

Yes the headstocks are adjustable on these.It's apart so it doesn't much matter now. It looks like it might be an adjustable headstock type but I can't tell from the pics. If it is then:

Get the bed into position and fixed down. Use a sensitive level to get the bed straight

Clean the headstock and bed and fit it up. Make test cuts to adjest the headstock for parallel cutting

Adjust the tailstock height and set-over for parallel turning between centres.

Front and read adjusters apparently although haven't discovered mine yet.

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Well spent all of last night looking through manuals and checking tooling didn't even have time to post more here but wow what a range of tooling I will catalogue it all so I know what I have and let you know , alot of brand new sandavick and other branded inserts aswell even everything I need to get started so that's great.

@Agroshield

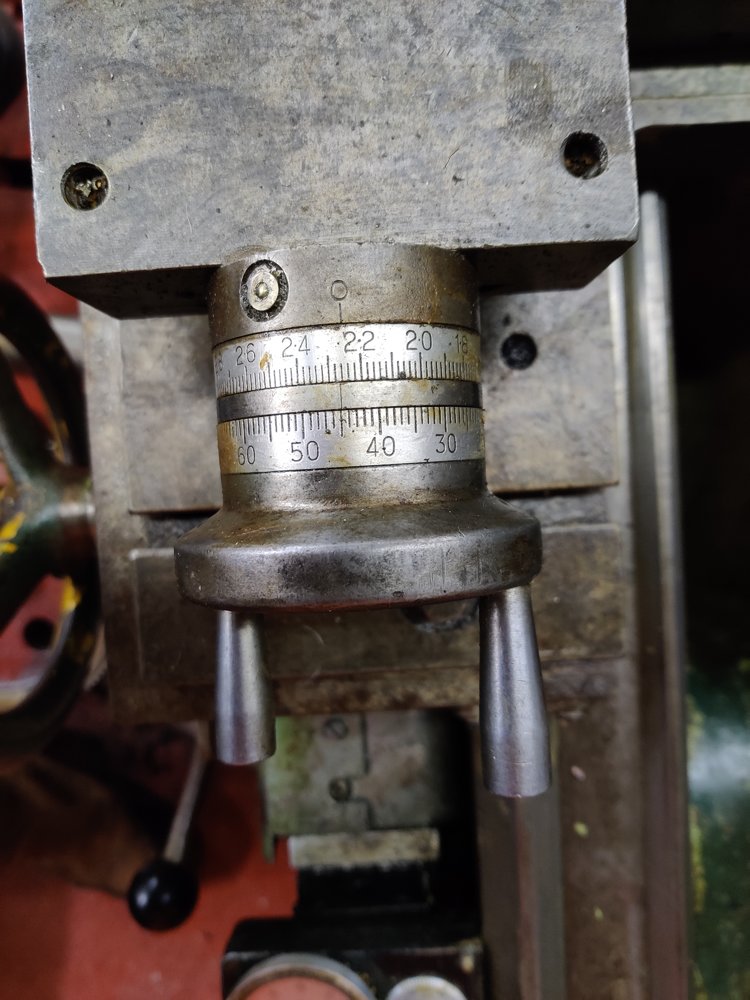

Here are the dials I checked with the dial guage and mag base and pretty sure the top is on 0.02mm a line and the bottom is in thou so indeed the dual dial machine which is great I'm mainly working in metric as that what I trained on however the choice of thou will come in handy I am sure

Can anyone identify what this is , it fits the chuck thread and taper

Will get some better photos of these later but they are the Pratt chuck , chucks for the faceplate which I didn't even know where included so big win and sure their quality made in England Pratt bunard or just says Pratt chucks

Only shame is they are numbered 1 to 4 however I am missing one think I have jaws number 1 , 2 and 4

One may have got lost in the last 60 years which would't suprise me not sure what I could do to replace first I will phone the seller and double check he's not got it still.

Will post some more later

@Agroshield

Here are the dials I checked with the dial guage and mag base and pretty sure the top is on 0.02mm a line and the bottom is in thou so indeed the dual dial machine which is great I'm mainly working in metric as that what I trained on however the choice of thou will come in handy I am sure

Can anyone identify what this is , it fits the chuck thread and taper

Will get some better photos of these later but they are the Pratt chuck , chucks for the faceplate which I didn't even know where included so big win and sure their quality made in England Pratt bunard or just says Pratt chucks

Only shame is they are numbered 1 to 4 however I am missing one think I have jaws number 1 , 2 and 4

One may have got lost in the last 60 years which would't suprise me not sure what I could do to replace first I will phone the seller and double check he's not got it still.

Will post some more later

Agroshield

Member

- Messages

- 5,698

Can anyone identify what this is , it fits the chuck thread and taper

Only shame is they are numbered 1 to 4 however I am missing one think I have jaws number 1 , 2 and 4

The first one is likely a spindle nose protector. If you are turning between centres or using the spindle taper to hold a collet, you do not want the chuck-securing nut to be rattling around. Sometimes they are made more elegantly/curvy than that one but the function is the same. People 3D print them nowadays. Needless to say, on no account install it with all that crud on the threads. Look how scrupulous Doubleboost is when he changes chucks - copy him.

Second ones are faceplate jaws. They effectively turn your faceplate into a giant 4-jaw chuck. Compare the stud length to the faceplate thickness to see if they play nicely. No big deal if one is missing. You might be able to pick up a set or partial set off eBay. Rotagrip probably sell them new.

Edit:

Best I have seen on the dual dials is this: https://www.circuitousroot.com/artifice/machine-shop/cr/colchester/repairs/dual-dials/index.html

You can search Espacenet and find the Gamet patent drawings as well.

For insight into how the faceplate jaws work, look on YT at Chris Maj and James Park Machining (turn screen sideways).

slim_boy_fat

Member

- Messages

- 29,540

- Location

- Scottish Highlands

@Lewis_RX8 Looks like you've bought yourself 'the gift that keeps on giving'  .

.

Looking forward to the reports

.

.Looking forward to the reports

Pete.

Member

- Messages

- 14,574

- Location

- Kent, UK

That thing might be a pot chuck adapter. Does it have a recess in the front with a bevelled inside edge?

Must say that is a well specified machine. Dual dials, ainjest threading, trav-a-dial and you have the steadies. All the bits that are normally robbed off it and sold separately. Bit of a jackpot TBH

Must say that is a well specified machine. Dual dials, ainjest threading, trav-a-dial and you have the steadies. All the bits that are normally robbed off it and sold separately. Bit of a jackpot TBH

Definitely.That thing might be a pot chuck adapter. Does it have a recess in the front with a bevelled inside edge?

Must say that is a well specified machine. Dual dials, ainjest threading, trav-a-dial and you have the steadies. All the bits that are normally robbed off it and sold separately. Bit of a jackpot TBH

He even had some long pieces of heavy bar stock thrown in free!

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

That thing might be a pot chuck adapter. Does it have a recess in the front with a bevelled inside edge?

Must say that is a well specified machine. Dual dials, ainjest threading, trav-a-dial and you have the steadies. All the bits that are normally robbed off it and sold separately. Bit of a jackpot TBH

Came off the RAF base so they must have went mad with the optional extras box like you say lol ticking everything most of the extras and on it. Really really pleased with it and old owner took the best care of it always cleaning and oiling everywhere in a home workshop environment no abuse.

Wasn't even in the eBay photos just chucked in aswell with alot of the other bitsDefinitely.

He even had some long pieces of heavy bar stock thrown in free!

, maybe two metres of 2" and a foot of 4" . 2" will be really handy for aligning the headstock also it fits through so a great stock to keep in the max that goes through spindle

, maybe two metres of 2" and a foot of 4" . 2" will be really handy for aligning the headstock also it fits through so a great stock to keep in the max that goes through spindleLewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

The first one is likely a spindle nose protector. If you are turning between centres or using the spindle taper to hold a collet, you do not want the chuck-securing nut to be rattling around. Sometimes they are made more elegantly/curvy than that one but the function is the same. People 3D print them nowadays. Needless to say, on no account install it with all that crud on the threads. Look how scrupulous Doubleboost is when he changes chucks - copy him.

Second ones are faceplate jaws. They effectively turn your faceplate into a giant 4-jaw chuck. Compare the stud length to the faceplate thickness to see if they play nicely. No big deal if one is missing. You might be able to pick up a set or partial set off eBay. Rotagrip probably sell them new.

Edit:

Best I have seen on the dual dials is this: https://www.circuitousroot.com/artifice/machine-shop/cr/colchester/repairs/dual-dials/index.html

You can search Espacenet and find the Gamet patent drawings as well.

For insight into how the faceplate jaws work, look on YT at Chris Maj and James Park Machining (turn screen sideways).

Yup definitely want them cleaner they where just on for sale and he warned me they may not be 100% clean or tight on the headstock tapers so I have taken them off and will surgically clean down when I next put them in. Thanks for that

Should I apply any oil to anything going in the taper or is it just a clean surface that's needed

I see I assumed that was it and with my 21" faceplate can get some massive stuff on if I ever needed to. Them single chuck jaws seem to be going for a lot of money as a set on eBay no individual ones there at the moment but will wait and see , could be possible to build a less advanced one myself and just use it to take up slop in a part maybe? , And yes the studs seem to fit in the faceplate alright

Thanks for the link on the dials I'll have a good read over later for when I will use them.

Pete.

Member

- Messages

- 14,574

- Location

- Kent, UK

Oil the taper when it's got no chuck on it and wipe it over before you fit. A film of oil won't hurt the chuck fit but you don't want any chips at all on the male or the female taper when you tighten on the chuck. It'll put little tiny dings in both.

Agroshield

Member

- Messages

- 5,698

Thanks for the link on the dials I'll have a good read over later for when I will use them.

It's not necessary to know anything to be able to use them - it was more to assuage your curiosity if you wanted know how they work.

Mystic Meg prediction: once you ruin a couple of parts by following the wrong dial, you will be making a cover or shield to obscure whichever language you are not using (3D printed?).

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

It's not necessary to know anything to be able to use them - it was more to assuage your curiosity if you wanted know how they work.

Mystic Meg prediction: once you ruin a couple of parts by following the wrong dial, you will be making a cover or shield to obscure whichever language you are not using (3D printed?).

Intresting to see they having the same screw pitch but metric and English threads

Seems like a good idea and thought it might have something like that I've seen online but might be for other dual dial lathes

Pete.

Member

- Messages

- 14,574

- Location

- Kent, UK

Intresting to see they having the same screw pitch but metric and English threads

Seems like a good idea and thought it might have something like that I've seen online but might be for other dual dial lathes

They have gearing inside them that makes both scales read true. Most of them do that is, Denford get away with dual dials by using 10TPI screws so one turn is 100 thou or 2.54mm with 0.04mm error on the metric scale.