BChild

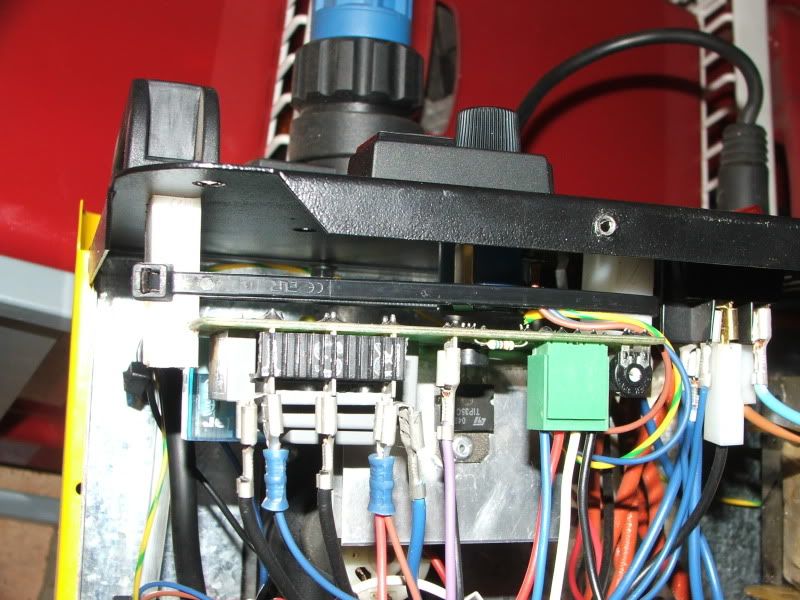

SIP - enough with the mods!!!!

- Messages

- 1,023

You'll be happy then?

I'm happier........ I spent a lot of time thinking it was me not the machine and that was frustrating I knew what to do and how to do it but nothing worked right

My recomendation would always be buy a decent welder if you can - but if you can't then modify what you have to make it better but only as a last resort

I think you're estimate on time is, let's say, conservativeI must have spent a couple of hours reading your interesting and compelling progress

Charging time, easy £25 per hour. First hour usually £35 each hour after £25.

I'd recon you've got easy 8 hours of tinkering, fiddling, coffee and biscuits, fitting, refitting, coffee and biscuits, writing, reading, coffee and biscuits, waiting! Fitting and failing, coffee and biscuits, refitting and testing etc.

It's a great result though, as many people don't cost their time into the equation so in that aspect a fine result.

It was a thought provoking series of questions and comments and for that I thank you sir - I think we all spend more time on stuff than we should or can justify if we costed it but the learning part pays dividends for future years - as far as electrickery goes wiring up a plug was about my limit till I bought this welder

Hope it prompts others to take little annoying idiosyncrasies of their machines and try to make them better, there are a lot of wire feed related issues with less expensive welders and as it's quite critical to success you're tenacity will I'm sure encourage others to do the same.

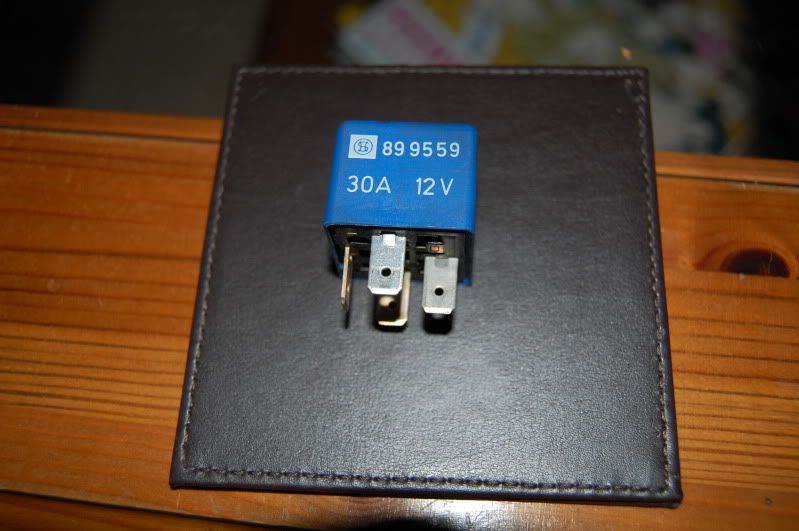

You know it could become the 'must have' welder, you should start buying them modifying and selling them on, get one over to TechnicalAl, Malcolm and others and ask for testimonials.

weldquip could be asking for exclusive distribution rights

well done that man!

Scarey thought and probably unlikely but it's been a journey of discovery and as I often say every day is a school day