dazza

Member

- Messages

- 2,203

- Location

- Barcelona

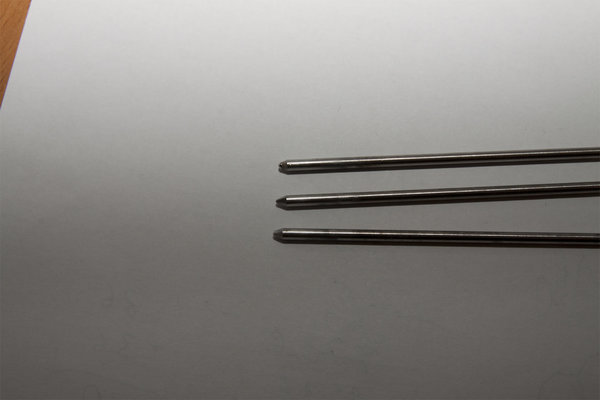

These are grey, all i could get over here.What tungstens are you using?

I took hotrodder's advice and tried Multi-strike. Its the only make I use now, regardless of size of tungsten or material been welded

I enjoyed it this afternoon it wasn't too bad, unlike the other days when prepping the tungsten was cutting off the ball and completely regrinding these just needed a tickle with the grinder and would spark up fine.I can only put it down to a weak HF Daz. It might be leaking down your torch or it may be leaking in the machine or it may just want the spark gap setting up if it works like that. Either way it's not the end of the world I've come across it on many units and I'd say 8 times out of 10 the torch causes the issue so you may be in luck once you get water cooled.

My magicwave wave had a similar issue with the standard fronius torch. I adjusted the HF settings which improved it a good bit but once I swappped over to the speedway it was on another level of striking. It will jump an inch gap with a fully balled electrode now and i wonder if you get similar results. A lot of Torches can leak HF making machines tough strikers.

We will see what its like with the pedal and new torch. If this does not fix the problem we will look into other solutions.

I did a couple of good runs today but i seem to struggle more with the first run (cold) the runs after when its hot flow nicely. Maybe i need a few more amps on the first run? I started at 125 amps then dropped it to 110.

I need to forget about the filler rod hand and just focus on the torch hand as this is where most of my problems are coming from.

I usually just move and dab with no pause, would it be better for a beginner to pause to add the filler?

I thought it was for AC. as its in the AC section of the machine the DC only machines did not have this. Glad i've turned it off.That's because it's for stick/mma/smaw welding