You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nibbler Table

- Thread starter 130

- Start date

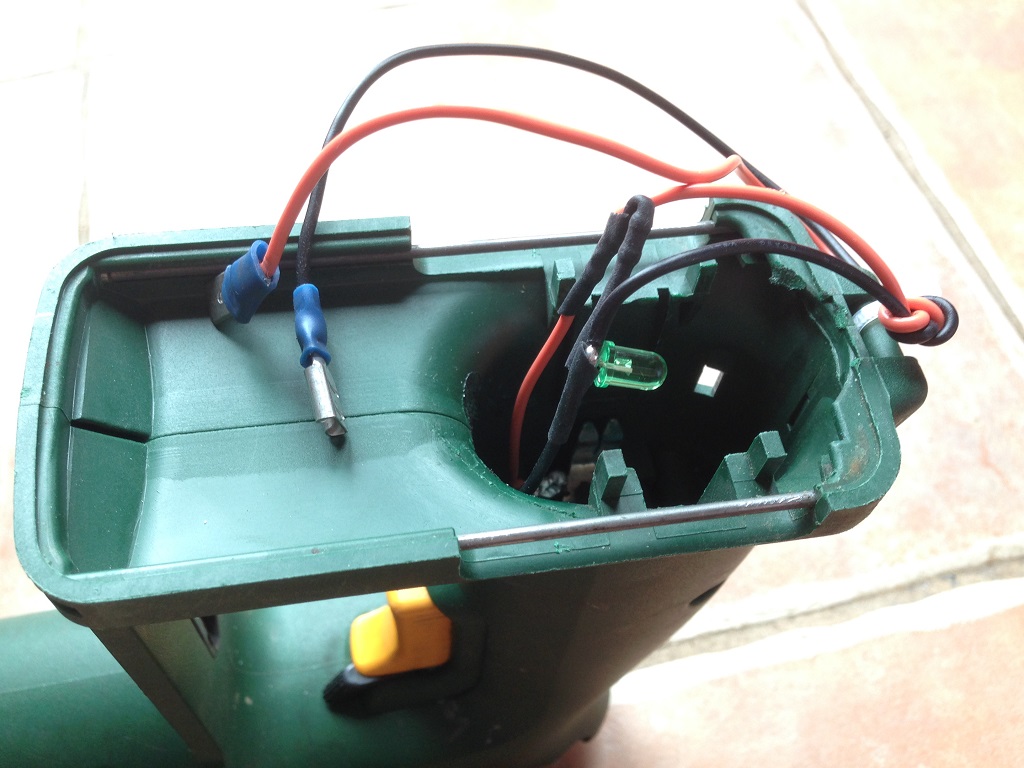

Take the best rechargeable drill I ever owned that has no batteries left, an LED and a resistor salvaged from an old router (power indicator)...…………..

And the crocodile clips and wire from an old battery charger, then mount the drill to a board, with shorter screws once bought

See centreline point on white nose bracket

The bolt and threads are printed, this is the tensioned to push the drill in tight.

Then print a sliding drill trigger part with threaded thumb screw for selecting a drill speed

And the crocodile clips and wire from an old battery charger, then mount the drill to a board, with shorter screws once bought

See centreline point on white nose bracket

The bolt and threads are printed, this is the tensioned to push the drill in tight.

Then print a sliding drill trigger part with threaded thumb screw for selecting a drill speed

Wallace

Member

- Messages

- 7,705

- Location

- Staines, Middlesex, England.

We think alike! I have a pair of Falcon nibblers one of which was damaged by an electrician who thought they should cut square steel trunking, I cobbled one up to a sheet of ply with a fence for cutting sheet into strips. Did a good job but what a mess those crescent chips make and they get EVERYWHERE!

I've had one get inside my boot and work it's way into my foot in rotation so I had to wind it out with pliers.We think alike! I have a pair of Falcon nibblers one of which was damaged by an electrician who thought they should cut square steel trunking, I cobbled one up to a sheet of ply with a fence for cutting sheet into strips. Did a good job but what a mess those crescent chips make and they get EVERYWHERE!

You'll like the rest of this post...………

Powered off car but upside down.

Can bag up the bits cut from the A side like this...……..

And the B side like this...………

I could print some grooves in the sides or the next and have a slide on swarf collector, but seeing as this is only a prototype at 10% fill and seems to do the job just fine I'll probably leave it.

I can easily do something but:dump the plastic bag and fit around a chute down to a collection box then when needed you can empty collection box and just carry on

a large enough one and it will take a while to fill up

- Solution has to work either way up, easy enough I already have a solution in mind but...…..

- Working is working, pareto principle, I've already got my 80%

rosinante

Member

- Messages

- 1,314

- Location

- Cornwall England

Very nice , re the chip collection , how about an electro magnet that is on a timer circuit so that the chips can drop off into a container cyclically or even just a switch to deenergise the magnet as the chips build up, might work with some experimentation,

Chris

Chris

addjunkie

Forum Supporter

- Messages

- 12,422

- Location

- Northumberland. Reet oot in the sticks

Except with non magnetic materialsVery nice , re the chip collection , how about an electro magnet that is on a timer circuit so that the chips can drop off into a container cyclically or even just a switch to deenergise the magnet as the chips build up, might work with some experimentation,

Chris

frank horton

V twins are great but 4"s rule.........

- Messages

- 4,094

- Location

- Crete, Greece

must be nice to have and to know how to use a 3D printer........hahaha.........I'll have to wait till my next rebirth.........hahaha.......

great idea.......

great idea.......

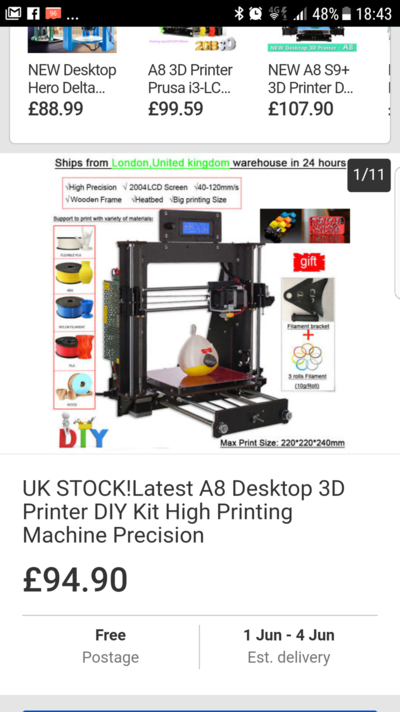

Come down in price now..FYI the printer is a £130-ish Anet A8 and drawn using FreeCad 2

Same thing I printed a few bits for the welder on recently

https://m.ebay.co.uk/itm/UK-STOCK-L...0c45fffde455&_mwBanner=1&_rdt=1&ul_noapp=true

I might even buy one to play with...

Olderisbetter

Member

- Messages

- 3,741

- Location

- Wolverhampton

I only recently found out that 3d printed things are quite strong, I always presumed they were soft and weak now i want a 3d printer to experiment with.

bigegg

Scream Not Working Because Space Make Deaf

- Messages

- 9,557

- Location

- Leeds, West Yorkshire

For c.£150, it's a no-brainer really. I have probably a dozen projects *now* for a 3d printer

First is a new fan cover for the back of my planer motor:

a new cover is going on £15.

It can also be used for making casting patterns, and some custom tool holders for my ongoing, long term, "studley style" tool cabinet project.

<Looks at bank account>

Not this week though...

First is a new fan cover for the back of my planer motor:

a new cover is going on £15.

It can also be used for making casting patterns, and some custom tool holders for my ongoing, long term, "studley style" tool cabinet project.

<Looks at bank account>

Not this week though...

Or have a look at FreeCad 2, you cold install it for erm free. The two easiest way to do things are sketch, so you draw a flat drawing and pad it to a thickness, or draw a sketch on a face of something to make lumps and holes as applicable, or you use "primitives" which is just normal shapes like cylinders and cubes, cones etc and put them together or subtract them. Seriously the tutorials make it easy plus a learning curve. I could draw in first or third angle but had never used cad before.must be nice to have and to know how to use a 3D printer........hahaha.........I'll have to wait till my next rebirth.........hahaha.......

great idea.......

I don't see the "Anet A8" name in that listing frame looks sturdier than mine but also mentioned wood, I tend to think acrylic is more stable shape wise, if not rigidity wise...…. but the second thing you print after a test piece are printer improvements, usually from some one else's designs on a site such as thingiverse.com

50 quid less...For c.£150, it's a no-brainer really. I have probably a dozen projects *now* for a 3d printer

First is a new fan cover for the back of my planer motor:

a new cover is going on £15.

It can also be used for making casting patterns, and some custom tool holders for my ongoing, long term, "studley style" tool cabinet project.

<Looks at bank account>

Not this week though...

Ignore this its cheap but not the same....see my other posts..

rosinante

Member

- Messages

- 1,314

- Location

- Cornwall England

Are they used much on non ferrous materials?Except with non magnetic materials

Ah i see..lolOr have a look at FreeCad 2, you cold install it for erm free. The two easiest way to do things are sketch, so you draw a flat drawing and pad it to a thickness, or draw a sketch on a face of something to make lumps and holes as applicable, or you use "primitives" which is just normal shapes like cylinders and cubes, cones etc and put them together or subtract them. Seriously the tutorials make it easy plus a learning curve. I could draw in first or third angle but had never used cad before.

I don't see the "Anet A8" name in that listing frame looks sturdier than mine but also mentioned wood, I tend to think acrylic is more stable shape wise, if not rigidity wise...…. but the second thing you print after a test piece are printer improvements, usually from some one else's designs on a site such as thingiverse.com

We can use fly paper for the non ferrous.Are they used much on non ferrous materials?

Got to admit though, the bag scales