Sawdustmaker

New Member

- Messages

- 10

- Location

- South Carolina USA

Not many people have that sort of info jim I've read many forums of people wanting to get a pedal but not pay ridiculous oe prices for them. You certainly know your stuff mate.I have a simple wiring diagram that I knocked up for these pedals years ago so I could convert my Fronius hire machines from expensive pedals to sensible ones. I can post it up if needed.

Hi Jim,

I am looking for wiring diagram from TR52mc for my welder, it would be greate, if you could send it to me.

Thanks a lot in advance!!

Regards,

Daniel

A little bit of more bad news for you. Your ck tig torch ain’t fitting that machine either. It’s an odd shaped gas through dins plug. ....

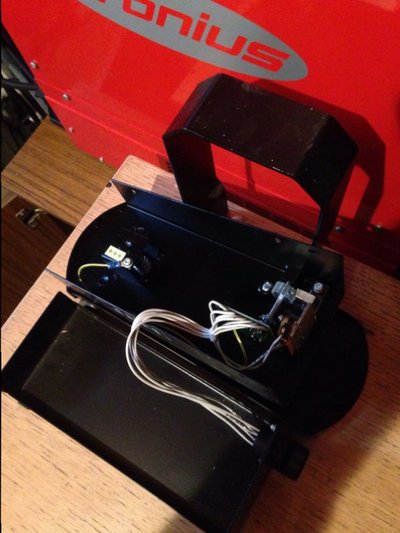

It can be made easilyYou got any pics of it Richard?

Could it not be made relatively easily?

Well no it hasn’t. You’ve bought just about the best kit money can buy.ohh, thanks Richard.

I can always relist it I guess, shouldnt lose too much.

Some guy is using CAN bus on a project in work. It is a bit subtle. Your right its difficult. I can do the hardware design to produce CAN differential signals.

What is difficult is finding the CAN ID for the pedal which will be unique and then how the pot or rotary encoder position is converted to data, often a CRC (Cyclic redundancy check) is computed and added to the sent word.

There is a guy on you tube doing it with a pot into a small uprocessor. If he helps me Im in with a fairly remote chance.

Looks like Ive stitched myself up here, just about the worst mistake Ive ever made.

Take it on the chin and reassess. That will teach me not to be so selfish with the family kitty.

I can use it as a stick welder for a while. This dream has slid into a mare

Thanks again