You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your bench vice(s)

- Thread starter MattF

- Start date

Arc Tourist

Member

- Messages

- 4,929

- Location

- Wales

Arc Tourist

Member

- Messages

- 4,929

- Location

- Wales

25.4_mechanic

Member

- Messages

- 1,046

- Location

- Germany, southwest

I took a few photo's not sure if these are ok but let me know. They're of a Parkinson No6.

Hey Vono,Carsten, here's some more

you've done a hell of a job!

I thank you very much for your effort.

By comparing and relating, I should be able to recreate the dimensions of the missing parts, along with measurements on my vice.

One more thing: I only have the spring from my Woden 190/7A as a comparison so far, they are 21 coils, a coiled part of 72mm length, the outer diameter is 20mm, the wire thickness 2.4mm, so the inner diameter should be about 15.2mm and thus the spring should lie quite loosely on the 1/2" round material.

Are these roughly standard dimensions for Parkinson's as well? I counted 20 coils in your picture, right?!?

Thanks again.

I was talking about gold leaf, and my Wife said she had some metallic pens.

That does look very good Mike, congratulations.

You should ask your wife more often anyway - says my wife ...

Have a nice evening all

Carsten

--

Hello Carsten, no problem you're welcome.Hey Vono,

you've done a hell of a job!

I thank you very much for your effort.

By comparing and relating, I should be able to recreate the dimensions of the missing parts, along with measurements on my vice.

One more thing: I only have the spring from my Woden 190/7A as a comparison so far, they are 21 coils, a coiled part of 72mm length, the outer diameter is 20mm, the wire thickness 2.4mm, so the inner diameter should be about 15.2mm and thus the spring should lie quite loosely on the 1/2" round material.

Are these roughly standard dimensions for Parkinson's as well? I counted 20 coils in your picture, right?!?

Thanks again.

That does look very good Mike, congratulations.

You should ask your wife more often anyway - says my wife ...

Have a nice evening all

Carsten

--

I'll take a couple of more pictures of the spring tomorrow, so that might help

Arc Tourist

Member

- Messages

- 4,929

- Location

- Wales

Thanks. The metallic pen has a very hard porous tip, so it was easy to follow the top of the raised lettering without going over. Also, the gold seems to have a fine satin look, which blends in well with the age of the patina on the vice's. It doesn't look new, but looks like its always been there.That does look very good Mike, congratulations.

You should ask your wife more often anyway - says my wife ...

Have a nice evening all

Carsten

--

25.4_mechanic

Member

- Messages

- 1,046

- Location

- Germany, southwest

Thanks. The metallic pen has a very hard porous tip, so it was easy to follow the top of the raised lettering without going over. Also, the gold seems to have a fine satin look, which blends in well with the age of the patina on the vice's. It doesn't look new, but looks like its always been there.

I always find it tragic on youtube to see a very successful vise restoration with the greatest effort and mechanical excellence, where the performer ends up messing everything up by absolutely having to take a brush and tracing the lines of writing in bright white and thus failing.

You have clearly found the better method!

Sorry, your wife has.

Sorry, your wife has.

Happy Sunday to all

Carsten

--

Arc Tourist

Member

- Messages

- 4,929

- Location

- Wales

She is brilliant. I wouldn't have returned half way across the world to marry just anyone................. You have clearly found the better method!Sorry, your wife has.

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

Hello all, been reading alot on here recently, today's find made me finally join up.

I went out looking for another old vice to play with and found what I could only dream of finding!

Super happy.

However, it is rusted solid. Nothing moves. Handle doesn't even move in the spindle nose.

I have recently been de rusting with citric acid but considered electrolysis for this but I am worried a little about embritlement.

I really don't want to weaken the vice!

It's cast steel.

I can't think of any other option though, considering it has no chance of coming apart. Diesel soak to get it apart then manual rust removal?

Or am I worrying too much about issues that aren't a problem.

Thanks.

I went out looking for another old vice to play with and found what I could only dream of finding!

Super happy.

However, it is rusted solid. Nothing moves. Handle doesn't even move in the spindle nose.

I have recently been de rusting with citric acid but considered electrolysis for this but I am worried a little about embritlement.

I really don't want to weaken the vice!

It's cast steel.

I can't think of any other option though, considering it has no chance of coming apart. Diesel soak to get it apart then manual rust removal?

Or am I worrying too much about issues that aren't a problem.

Thanks.

Hello CarstenHey Vono,

you've done a hell of a job!

I thank you very much for your effort.

By comparing and relating, I should be able to recreate the dimensions of the missing parts, along with measurements on my vice.

One more thing: I only have the spring from my Woden 190/7A as a comparison so far, they are 21 coils, a coiled part of 72mm length, the outer diameter is 20mm, the wire thickness 2.4mm, so the inner diameter should be about 15.2mm and thus the spring should lie quite loosely on the 1/2" round material.

Are these roughly standard dimensions for Parkinson's as well? I counted 20 coils in your picture, right?!?

Thanks again.

That does look very good Mike, congratulations.

You should ask your wife more often anyway - says my wife ...

Have a nice evening all

Carsten

--

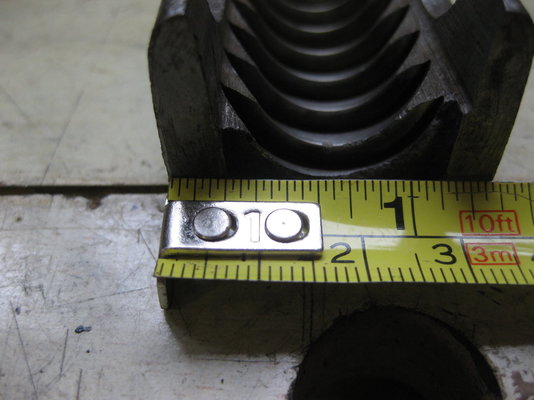

As promised some QR spring pics

Hope they help

25.4_mechanic

Member

- Messages

- 1,046

- Location

- Germany, southwest

However, it is rusted solid. Nothing moves. Handle doesn't even move in the spindle nose.

Welcome Greame,

I can only warmly recommend it here, I have recently been very kindly welcomed myself!

First you should say what type of vice it is (front or rear opening), prism tracks, should the nut turn or the spindle, spindle protected or unprotected, how big is the part (will it fit in an ultrasonic bath)????

Pictures usually help too.

I would do it like this:

- Hot soak and wash with household grease solvents so as not to mess up later agents with dirt;

- Rinse with water, pressure washer;

- Soak in hot citric acid solution, several times if necessary, the surfaces should have changed their appearance;

- Rinse with water;

- Blow dry with compressed air and continue drying with a hair dryer or similar;

- Soak in a penetrating oil of your choice;

- Try to move the controls again and again over a period of days in the penetrating oil;

- Resilience is more important than strength;

- Change position, let the oil run in and out of cavities;

- Replace penetrating oil that is saturated with dirt;

- If nothing moves after a week, ask again with further information.

I never had to go further. Someone else must help from there

Good success!

Carsten

--

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

Welcome Greame,

I can only warmly recommend it here, I have recently been very kindly welcomed myself!

First you should say what type of vice it is (front or rear opening), prism tracks, should the nut turn or the spindle, spindle protected or unprotected, how big is the part (will it fit in an ultrasonic bath)????

Pictures usually help too.

I would do it like this:

- Hot soak and wash with household grease solvents so as not to mess up later agents with dirt;

- Rinse with water, pressure washer;

- Soak in hot citric acid solution, several times if necessary, the surfaces should have changed their appearance;

- Rinse with water;

- Blow dry with compressed air and continue drying with a hair dryer or similar;

- Soak in a penetrating oil of your choice;

- Try to move the controls again and again over a period of days in the penetrating oil;

- Resilience is more important than strength;

- Change position, let the oil run in and out of cavities;

- Replace penetrating oil that is saturated with dirt;

- If nothing moves after a week, ask again with further information.

I never had to go further. Someone else must help from there

Good success!

Carsten

--

That's pretty much what I had planned, just wasn't sure if to use the citric, or replace that step with electrolysis.

I have done a fair bit of citric de rusting recently (every steel part of a 1950s motorcycle). But since then I've also been electroplating stuff (every nut bolt washer and chrome part of a 1950s notorcycle).

That's why I wondered about trying to remove rust that way. Maybe I'll try citric first as it's not line of sight.

The vice in question...

A rare one, but apart from the missing jaw, and not one single part still moving, it seems ok. Doesn't seem to have had much abuse.

I just don't want to weaken it. It won't get abused, I use my record 112 for abusive jobs, but it's going to be a reasonable amount of work to sort out so I don't want the dynamic jaw to fall off first time I clamp anything down in it!

25.4_mechanic

Member

- Messages

- 1,046

- Location

- Germany, southwest

Hi Vono,Hello Carsten

As promised some QR spring pics

Hope they help

thank you very much.

I count 20 turns. What is the wire diameter? What is the outer diameter of the spring?

From the other pictures I deduce a length of the coiled part of the spring of something like 60-65mm, is that about correct?

Thanks.

Carsten

--

CwazyWabbit

Member

- Messages

- 699

- Location

- Surrey, UK

A nice Fortis you have there, I wouldn't worry about embrittlement, I've used electrolysis on a number of vices now without issue.That's pretty much what I had planned, just wasn't sure if to use the citric, or replace that step with electrolysis.

I have done a fair bit of citric de rusting recently (every steel part of a 1950s motorcycle). But since then I've also been electroplating stuff (every nut bolt washer and chrome part of a 1950s notorcycle).

That's why I wondered about trying to remove rust that way. Maybe I'll try citric first as it's not line of sight.

The vice in question...

View attachment 315865

A rare one, but apart from the missing jaw, and not one single part still moving, it seems ok. Doesn't seem to have had much abuse.

I just don't want to weaken it. It won't get abused, I use my record 112 for abusive jobs, but it's going to be a reasonable amount of work to sort out so I don't want the dynamic jaw to fall off first time I clamp anything down in it!

I'd go with electrolysis first if it was mine.

MattF

Forum Supporter

- Messages

- 16,929

- Location

- South Yorkshire

I wouldn't worry about embrittlement, I've used electrolysis on a number of vices now without issue.

I'd go with electrolysis first if it was mine.

Same here.

25.4_mechanic

Member

- Messages

- 1,046

- Location

- Germany, southwest

That's pretty much what I had planned, ju

Yes, certainly a interesting piece.

So you have experience with electrolytic processes, that's good.

One should never advise it to someone who has never done it and whose skills and knowledge one cannot estimate.

For me, electrolytic rust removal would come after all the other measures.

Carsten

--

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

Ok, maybe I'll give electrolysis a go. I have everything to do it.A nice Fortis you have there, I wouldn't worry about embrittlement, I've used electrolysis on a number of vices now without issue.

I'd go with electrolysis first if it was mine.

As it's line of sight, I guess it would be best to try and get it apart first, then do the pieces individually?

My be a citric soak first will loosen it all up. Might try and get the quick release mech out first though so as not to risk damaging the spring.

MattF

Forum Supporter

- Messages

- 16,929

- Location

- South Yorkshire

For me, electrolytic rust removal would come after all the other measures.

With me, it would be the first approach. I'm really not a fan of citric.

CwazyWabbit

Member

- Messages

- 699

- Location

- Surrey, UK

If it is stuck solid I'd chuck it in whole and run it for a while, take it out and pressure wash it (as I can be a bit lazy), then try taking it apart. If it won't come apart still try another go in the electrolysis tank and repeat. You have nothing to lose but time and it may stop you damaging/breaking bits.Ok, maybe I'll give electrolysis a go. I have everything to do it.

As it's line of sight, I guess it would be best to try and get it apart first, then do the pieces individually?

My be a citric soak first will loosen it all up. Might try and get the quick release mech out first though so as not to risk damaging the spring.

25.4_mechanic

Member

- Messages

- 1,046

- Location

- Germany, southwest

I'd go with electrolysis first if it was mine.

Same here.

Ok, why would you be going around like this?

I always find it an unnecessary mess in that order.

But I am always eager to learn more!

Carsten

--