Blobber

Member

- Messages

- 2,793

- Location

- lincolnshire

You are most welcome to my club, I dont call myself Blobber for nothing!Fortunately the blurry photo masks my shocking tig welding.

Thanks for educating me @Moose McAlpine .

You are most welcome to my club, I dont call myself Blobber for nothing!Fortunately the blurry photo masks my shocking tig welding.

Thanks for educating me @Moose McAlpine .

The chutes just need lining in either ceramic or linatex. Depending on the abrasion/impact.That could end up looking like a chute we frequently repaired down at a local quarry. Virtually every member of the team went out and patched it when it wore through so it ended up looking like one of those Aztec pyramids laid on its side as each patch was smaller than the last. The quarry firm was too tight to replace the chute.

I think I've gas issues, had gas issues for a while

That hopper fix looks OK, you deserve a drink - have one on me.

That hopper fix looks OK, you deserve a drink - have one on me.

, last night finally got time to bolt it all back together, and test ran, equals an almost fully working motorbike.... Aprilia 650 Pegaso starts and runs, everything works, had it out for a wee run this morning, that's the cobwebs gone then, bike and me

, last night finally got time to bolt it all back together, and test ran, equals an almost fully working motorbike.... Aprilia 650 Pegaso starts and runs, everything works, had it out for a wee run this morning, that's the cobwebs gone then, bike and me ..... ...

..... ...

If there wasn't so much plastic in the proximity I probably wouldn't get to excited about it either, but you can see it's been melted quite a bit... They're renowned for it apparently..@MCKDAVID

The headers used to glow red on my T150 Trident when idling a long time stationary (waiting to board the IOM ferry). If they are single skin pipes and the plug is right I wouldn't worry about it too much.

Dread to think what was leaking out of it.

Nice.........Begins with an s and ends in t !

That's actually waste water from a compressor plantroom , they didn't glue the strap on boss to the soil pipe hence the detritus running down the outside ! Been leaking for a while

Begins with an s and ends in t !

don't know where you'd get a specific one, but you would most likely be able to pick up a standard pipe nipple with the right thread sizes easily enough, if you have the room to get it in?I got this old compressor a few months back and finally had a go at fixing the leaks.

View attachment 301671

It leaked on the outlet of the tank and after a bit of heat I got the union out and found this

View attachment 301672

If anyone knows where I can get a new one let my know.

In the end to get it working I just fitted a PCL tail and a quick release fitting,

View attachment 301675

The pressure gauge was unreadable so I cleaned it with a bit of T Cut and it came out ok,

Before,

View attachment 301673

After,

View attachment 301674

All working

Bear in mind I'm talking 30+ years backThe chutes just need lining in either ceramic or linatex. Depending on the abrasion/impact.

Ceramic tile lining does welders out of a job, if done properly it can outlast any metallic wear plate or hardfaced tube.

Do it on occasion. Also the tubes which are hardfaced internally on a bore welder.

Most of the quarries down my way, then, didn't have that kind of money so for them, repair or lining with old belt rubber was the usual fix. Where we could we'd try to improve on the internal design without compromising material flow but that often only gave a short lease of life.

Most of the quarries down my way, then, didn't have that kind of money so for them, repair or lining with old belt rubber was the usual fix. Where we could we'd try to improve on the internal design without compromising material flow but that often only gave a short lease of life.

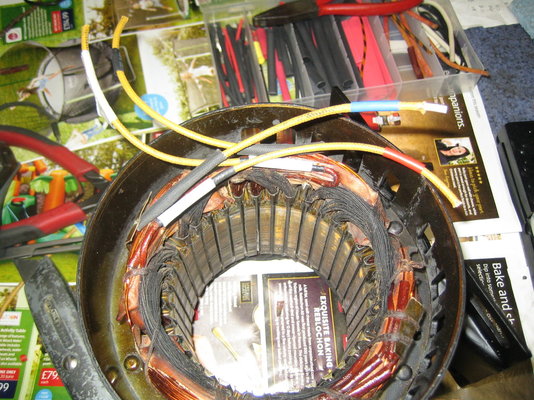

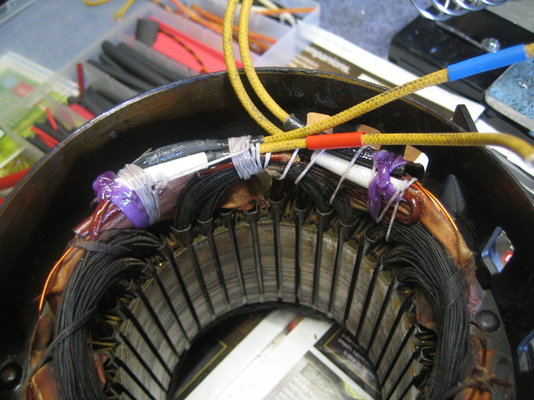

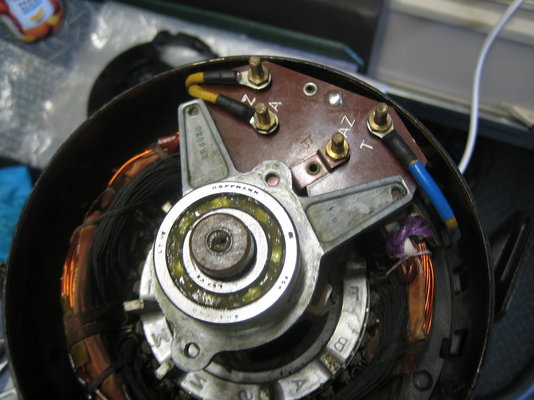

Kin hell. Not your buckets I hope?!Today I fixed the dishwasher because the motors hatitself. New one turned up on a clickncollect service next day

Fubared after it ate some glass that somehow got past the filter

View attachment 301844

View attachment 301843

Then made myself ill by letting a mate loose in the workshop so he could make a total balls up of repairing a couple of digger buckets. Complete waste of gas and mig wire

View attachment 301845

Had something similar happen some years ago. I think a little chunk of debris fell into the dishwasher sump while I had the filter screen pulled out for a few minutes for its monthly cleaning. Can't remember what the debris was...might have been a rivet from some salad tongs or something like that.Today I fixed the dishwasher because the motors hatitself. New one turned up on a clickncollect service next day

Fubared after it ate some glass that somehow got past the filter