Migmac

Forum Supporter

- Messages

- 8,308

- Location

- Kintyre. Scotland

put a seat that's 70 years plus on a horse thingy, the guy rang me today couldn't thank me enough as the seat belonged to his dad View attachment 304905

Is that for racing ?

put a seat that's 70 years plus on a horse thingy, the guy rang me today couldn't thank me enough as the seat belonged to his dad View attachment 304905

Never show my wife that picture!Shame you don't live a tad closer

Said for racing training and jogging, it came from the states, said i could take it to take measurments ect, if there was a market for them like he said there would be i'd have a go at it they cost around 2000Is that for racing ?

When you see that you should take a log splitter and charge them for splitting itShame you don't live a tad closer

I know your ploy, you're trying to get me to watch your random video links - well, I'm not falling for that one, once bitten etc......

I stopped trusting his links a long time ago.

I stopped trusting his links a long time ago.

I had the same issue on my Karcher but was able to get a new part and problem solved unless you are looking for an excuse to get a new oneToday I didn't fix the pressure washer.

View attachment 305049

What I did do is spill a lot of the (Rather water-contaminated) oil and determine the leak is coming from two of the three cracked plastic cylinders. Presumably its been allowed to freeze, no fixing it. It does still work, just very leaky. I've put it back together and will continue using it until it properly dies.

Didn't even think to look for parts, I assumed it was considered non-serviceable. New cylinder head is twenty quid.I had the same issue on my Karcher but was able to get a new part and problem solved unless you are looking for an excuse to get a new one

Didn't even think to look for parts, I assumed it was considered non-serviceable. New cylinder head is twenty quid.

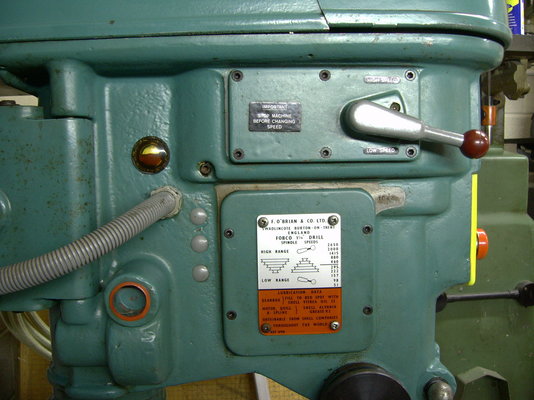

Looks very tidyUnloaded the drill press into the garage, and got the scissor mechanism working for the belt tensioner, which was froze up. The previous owner said he had acquired the Fobco as part of a job lot of machinery about 20 years ago, and rarely ever used it. I also spent some time cleaning off the dried oil and grease on the head which revealed a nice paint finish beneath. I just need to get some help or a bottle jack to put on top of the column with a sling to raise it up. The drill came with a 5/8" capacity chuck, but I think I'll install a 3/4" Jacobs super chuck on it.

View attachment 305096 View attachment 305097 View attachment 305098 View attachment 305099

Very happy so far. I can't see any damage and everything else works smoothly. It was installed in a really nice residential garage away from the weather and under a cover, kind of like out of a time capsule. Its three phase, so need to get a proper converter, but will leave that to an electrician.Looks very tidy

Get @Parm to 3D print some new cylindersToday I didn't fix the pressure washer.

View attachment 305049

What I did do is spill a lot of the (Rather water-contaminated) oil and determine the leak is coming from two of the three cracked plastic cylinders. Presumably its been allowed to freeze, no fixing it. It does still work, just very leaky. I've put it back together and will continue using it until it properly dies.

Ended up raising the drill head by myself using a small trolly jack and some lengths of four by two's, which worked a treat; then cut up some pipe to roll the press on, to its new home at the far end of the garage. Just need to get a proper phase converter installed, and job is done.Unloaded the drill press into the garage, ................................just need to get some help or a bottle jack to put on top of the column with a sling to raise it up. ....................

View attachment 305098

I am deeply envious - lovely piece of kit.Ended up raising the drill head by myself using a small trolly jack and some lengths of four by two's, which worked a treat; then cut up some pipe to roll the press on, to its new home at the far end of the garage. Just need to get a proper phase converter installed, and job is done.

View attachment 305283 View attachment 305284

Ended up raising the drill head by myself...

I tried the quill idea, and quickly abandoned that thought. The very close tolerance of the column fit required that the lift be as close to it as possible. Applying pressure further outward only caused binding. The table is quite heavy in and of itself, and took some effort to raise. I would think its possible to use the mechanism to raise the head, but I would be reluctant to, as seems it would be putting "a lot" of stress on the crank.Now I see what you have done, I wonder if in the future you need to raise or lower the head, you could use the table raising mechanism of the drill itself to do the same job. Even the quill of the machine might do it.

When ever I suggest them people moan about the priceGet a kramzle