You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Sergei Slovenija

Member

- Messages

- 1,267

- Location

- Slovenija Ljubljana

I'm sorry, I can't figure out what "yellow cans" are, what's the context in that? Red telephone booth - I understand that, but canisters?Nice one Sergei.

You cannot get the yellow canisters over there now? They are very common here in the UK.

I have a lot of gas cylinders for a forklift, a separate quest was to find a special adapter for this type of necks. It's good that I found it a couple of years ago, for a propane smelting furnace.

Our cans of propane are red, and they always run out suddenly. Oh yeah!

Pete.

Member

- Messages

- 15,074

- Location

- Kent, UK

I'm sorry, I can't figure out what "yellow cans" are, what's the context in that? Red telephone booth - I understand that, but canisters?

I have a lot of gas cylinders for a forklift, a separate quest was to find a special adapter for this type of necks. It's good that I found it a couple of years ago, for a propane smelting furnace.

Our cans of propane are red, and they always run out suddenly. Oh yeah!

magnet

Member

- Messages

- 1,451

Great machines those. Spent a lot of time alongside one of those as an apprentice........Happy dayzI can’t get the Vickers nibbler close enough to the wall to hardwire it in so I stuck an appliance inlet on it so I use a gurt big extension lead.

View attachment 327412

The grind on the cutters was way off so I get them corrected but I need to buy a finer grade wheel for future sharpening.

View attachment 327413

Now with the correct shape ground in it chews through 1.2mm mild like it’s nothing so I guess the tin snips can take a break.

View attachment 327414

Sergei Slovenija

Member

- Messages

- 1,267

- Location

- Slovenija Ljubljana

In the UK, the steering wheel in the car is on the wrong side and the license plates of the car are also yellow ... And gas cans too ...

It will be hard for me to sleep knowing this now

Blue Chips

Forum Supporter

- Messages

- 751

- Location

- Maine, USA

I'm currently installing PVC waste and vent pipes for an upstairs bathroom that we're adding in the old house we're restoring. To make my work a little easier, I fabbed up a very simple clamping jig to hold the pipe while I cut it. There's not much to it. I simply welded legs onto a piece of steel angle and softened the sharp corners of the angle to avoid making dings in the PVC. It's mounted on a piece of heavy plywood, which can be clamped to some sawhorses or whatever.

I clamp the pipe in place with a Vise-Grip chain clamp and a small piece of steel angle, and then I cut it with a Ridgid 154-P "quick acting" tubing cutter that has a special wheel for cutting plastic pipe. It makes a nice clean cut with no mess. I use a Reed DEB4 deburring tool to remove the outer burr and put a small chamfer on the edge. I use a swivel-type deburring tool to remove the inner burr.

To make it faster to select the correct chain clamp link for each pipe size, I applied dabs of five different colors of paint to the appropriate chain links for each pipe size. (Note: These photos were taken before I applied the color coding.)

Cutting a piece of 3" PVC pipe:

Removing the burr and chamfering 1-1/2" PVC pipe:

I clamp the pipe in place with a Vise-Grip chain clamp and a small piece of steel angle, and then I cut it with a Ridgid 154-P "quick acting" tubing cutter that has a special wheel for cutting plastic pipe. It makes a nice clean cut with no mess. I use a Reed DEB4 deburring tool to remove the outer burr and put a small chamfer on the edge. I use a swivel-type deburring tool to remove the inner burr.

To make it faster to select the correct chain clamp link for each pipe size, I applied dabs of five different colors of paint to the appropriate chain links for each pipe size. (Note: These photos were taken before I applied the color coding.)

Cutting a piece of 3" PVC pipe:

Removing the burr and chamfering 1-1/2" PVC pipe:

stuvy

Member

- Messages

- 9,304

The steering wheel is on the correct sideIn the UK, the steering wheel in the car is on the wrong side and the license plates of the car are also yellow ... And gas cans too ...

It will be hard for me to sleep knowing this now

Stop being like America

Mick Annick

Forum Supporter

- Messages

- 2,993

- Location

- Burgundy, France (450 miles SE of Somerset)

I still have a RHD car here, rarely a disadvantage other than for overtaking, but there’s so little traffic around here it’s not often I need to.

Until the late sixties(?) trucks in Italy were RHD - it was reckoned to be safer as they had a better view of the edge of the road in mountainous areas, and could see to get closer to buildings on narrow streets.

Until the late sixties(?) trucks in Italy were RHD - it was reckoned to be safer as they had a better view of the edge of the road in mountainous areas, and could see to get closer to buildings on narrow streets.

In the UK, the steering wheel in the car is on the wrong side and the license plates of the car are also yellow ... And gas cans too ...

It will be hard for me to sleep knowing this now

the little yellow gas bottles are MAPP gas, which is hotter than those propane torches etc. :-)

Sergei Slovenija

Member

- Messages

- 1,267

- Location

- Slovenija Ljubljana

This is a banter)) I drove with the right wheel for 20 years on the roads of the European standard.The steering wheel is on the correct side

Stop being like America

Sergei Slovenija

Member

- Messages

- 1,267

- Location

- Slovenija Ljubljana

In my opinion, we also have MAPP gas in red tins. And the price of it bites the pocketthe little yellow gas bottles are MAPP gas, which is hotter than those propane torches etc. :-)

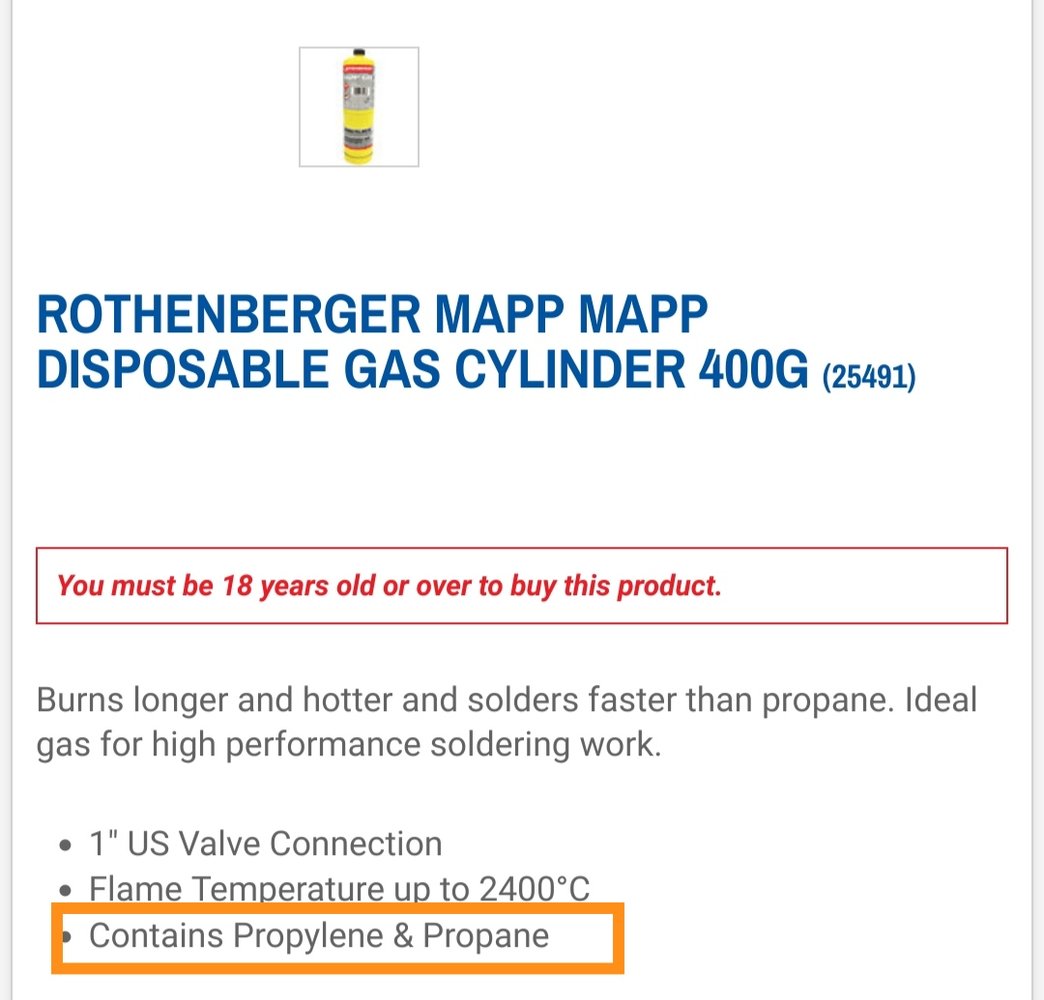

I have enough propane. I want to make a soldering torch, on compressed air + propane. MAPP is definitely not needed.

Example

Propene is the yellow one, no company has made MAPP since about 2008? Annoys me they label like that rather than whats in it.

Rothenberger MAPP Mapp Disposable Gas Cylinder 400g - Screwfix

Order online at Screwfix.com. Burns longer and hotter and solders faster than propane. Ideal gas for high performance soldering work. FREE next day delivery available, free collection in 1 minute.

??

unless original MAPP gas was different?

In my opinion, we also have MAPP gas in red tins. And the price of it bites the pocket

I have enough propane. I want to make a soldering torch, on compressed air + propane. MAPP is definitely not needed.

Example

you can buy oxygen generators you know?

saw some videos on YouTube years back where people use them for brazing

think most people had an oxygen generators (or a few) feeding into a small compressor - oxygen was only generated slowly and at low pressure, so the compressor stored it for them (just used a normal air compressor)

James1979

Member

- Messages

- 8,418

- Location

- Orkney

There was only one plant in the world making mapp and it stopped. I don’t know why it’s still called that, trade mark I suppose, but what you buy now isn’t the proper mapp.

Rothenberger MAPP Mapp Disposable Gas Cylinder 400g - Screwfix

Order online at Screwfix.com. Burns longer and hotter and solders faster than propane. Ideal gas for high performance soldering work. FREE next day delivery available, free collection in 1 minute.www.screwfix.com

??

unless original MAPP gas was different?

Edit:

You can read it here https://en.wikipedia.org/wiki/MAPP_gas

Kram

Member

- Messages

- 8,382

- Location

- Sussex

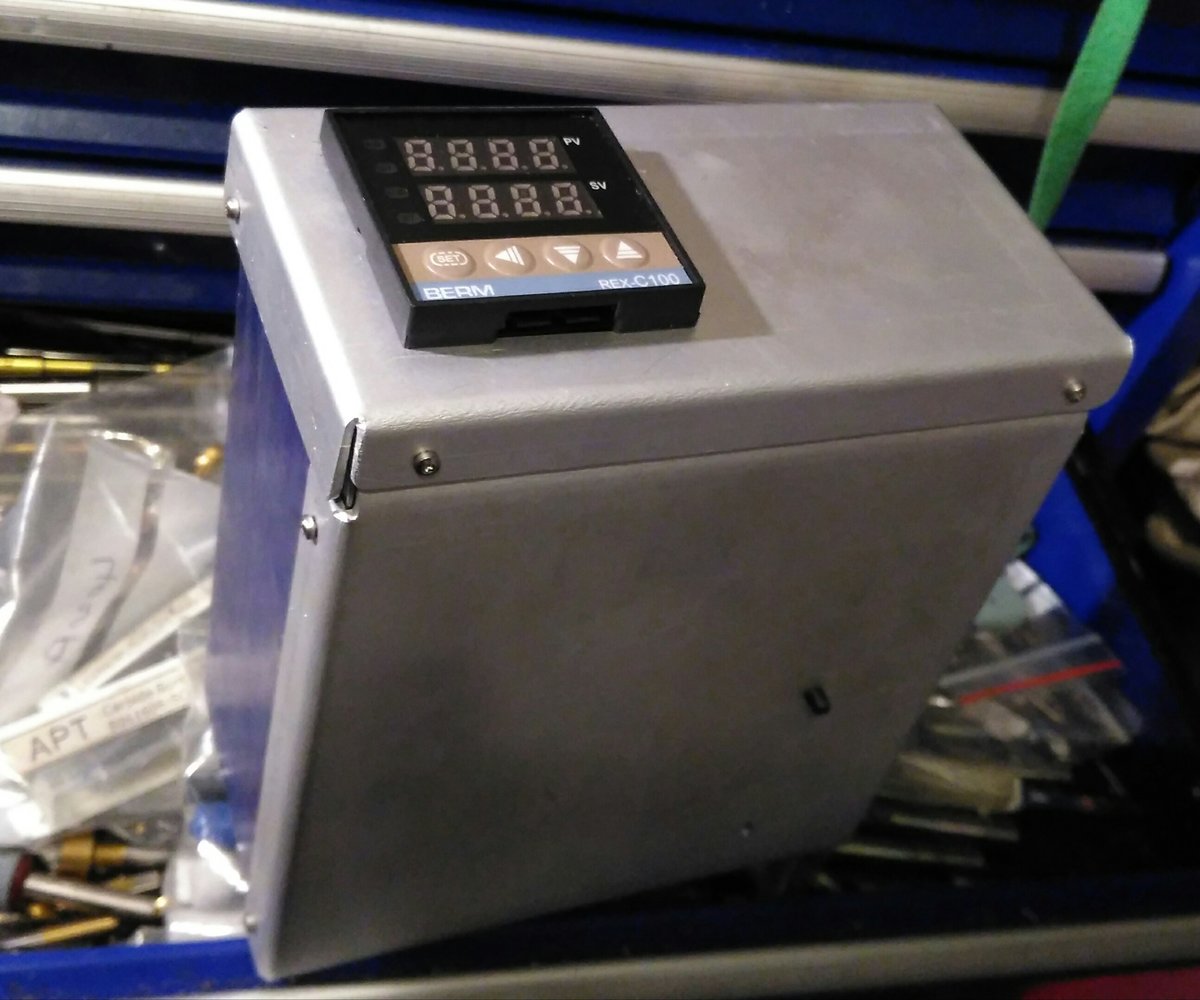

Control box, stripped the annodise and assembled with M2 screws but yet to affix the m2 nuts inside. I think Im going to regret it so may order a load of m3's.

I forgot to try stripping the marker off with NaOH.

(Propylene = propene)

I forgot to try stripping the marker off with NaOH.

Rothenberger MAPP Mapp Disposable Gas Cylinder 400g - Screwfix

Order online at Screwfix.com. Burns longer and hotter and solders faster than propane. Ideal gas for high performance soldering work. FREE next day delivery available, free collection in 1 minute.www.screwfix.com

??

unless original MAPP gas was different?

(Propylene = propene)

Dishing stump.

I've been meaning to have a go at this for a while. The video explains all.

A lump of tree out of my rapidly diminishing wood pile. Marked up with a four inch circle. Drilled two inches deep.

A bit more drilling and chiselling later gets me here. It still needs smoothing out a bit more really, but this job follows the 80/20 rule. The last bit to make it nice will be 80% of the effort. The idea is that the sheet metal is knocked into the void. The inner surface isn't a pattern or mould so as long as there is clearance it doesn't really matter what state it's in.

Bit of scrap sheet from other experiments.

About four minutes bashing with a hammer. I think the ball pein end of the hammer was a bit small. I would have liked a bigger radius on the tool, but it worked out nicely for a first go.

From start to finish I think it took me 80 minutes, tops. Definitely worth having a go.

I want a bigger stump now.

I've been meaning to have a go at this for a while. The video explains all.

A lump of tree out of my rapidly diminishing wood pile. Marked up with a four inch circle. Drilled two inches deep.

A bit more drilling and chiselling later gets me here. It still needs smoothing out a bit more really, but this job follows the 80/20 rule. The last bit to make it nice will be 80% of the effort. The idea is that the sheet metal is knocked into the void. The inner surface isn't a pattern or mould so as long as there is clearance it doesn't really matter what state it's in.

Bit of scrap sheet from other experiments.

About four minutes bashing with a hammer. I think the ball pein end of the hammer was a bit small. I would have liked a bigger radius on the tool, but it worked out nicely for a first go.

From start to finish I think it took me 80 minutes, tops. Definitely worth having a go.

I want a bigger stump now.

Sergei Slovenija

Member

- Messages

- 1,267

- Location

- Slovenija Ljubljana

After the rollers, the stainless steel sheet is under great stress. I would anneal the sheet to straw color, before and after forging in a mortarDishing stump.

I've been meaning to have a go at this for a while. The video explains all.