You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Hood

I am obsessed.

- Messages

- 17,478

- Location

- Carnoustie, Scotland

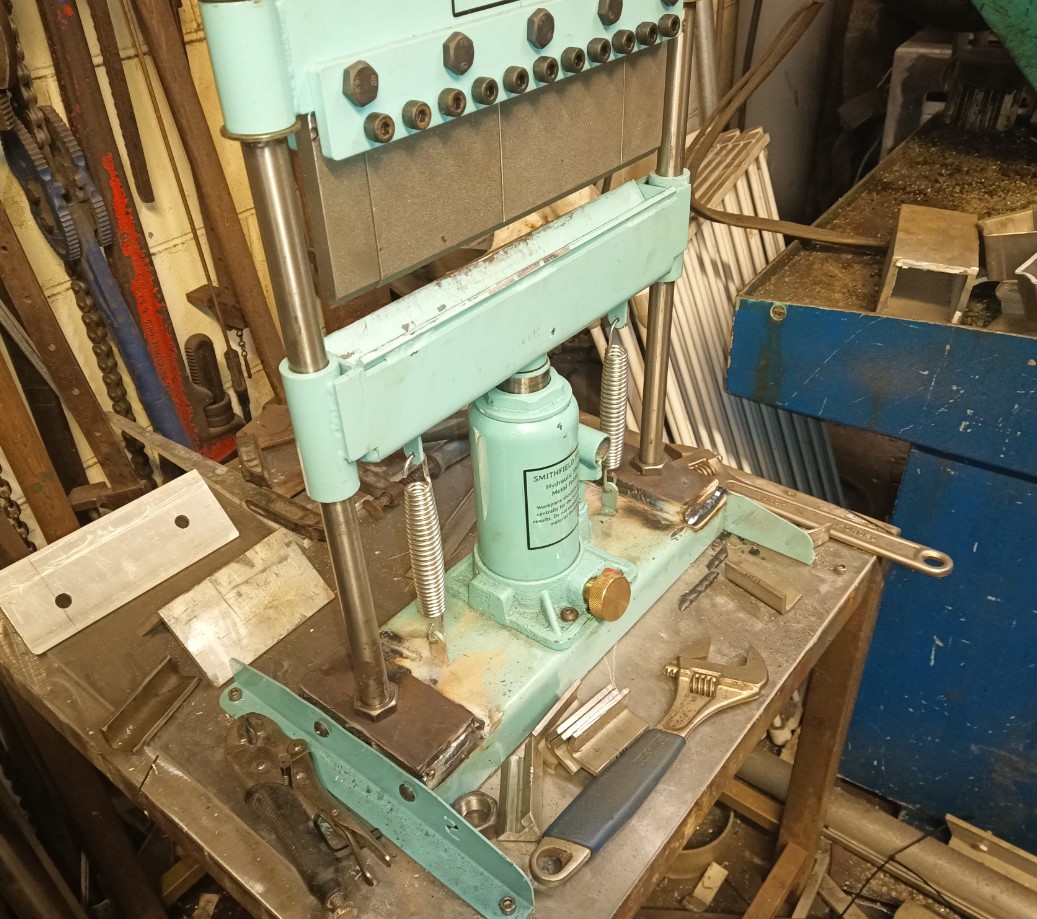

Made my wee press better again after I abused it by trying to bend double the thickness with a reduced die, it started pulling up the base plate. So bored and tapped some 10mm steel and welded in place, will be much stronger but I will not overload it so much next time

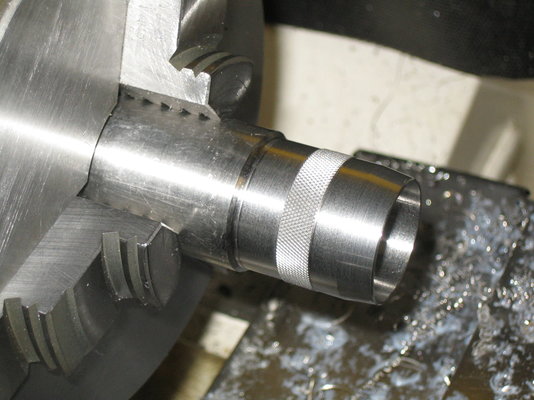

Also used the CNC lathe for the first time in months, well that is not true as I have done loads of hauler plates but that is all, not done any threads for a long long time as mostly I have just used the manual lathe when needing any, not sure why as CNC is much quicker and easier

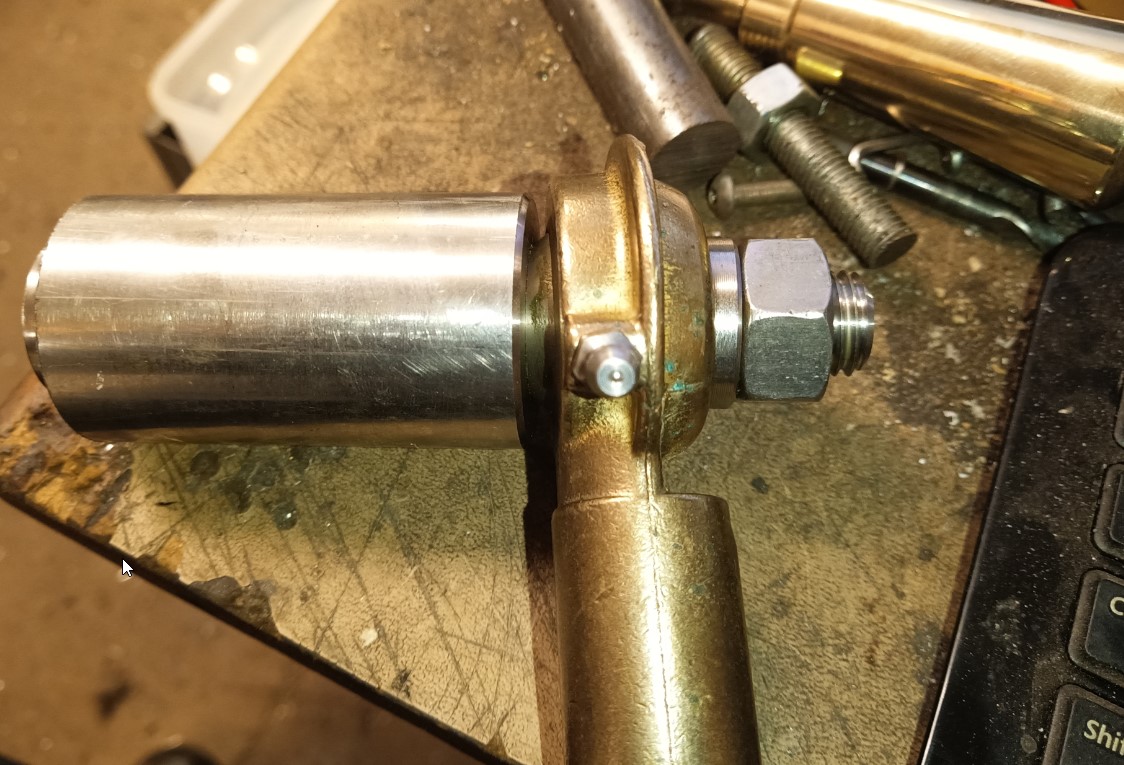

Turned some 40mm OD 316 down to 3/4" then put an M16 male thread on the end.

It is a fixing for a steering ram and will be welded to the steering rod at some point.

Also used the CNC lathe for the first time in months, well that is not true as I have done loads of hauler plates but that is all, not done any threads for a long long time as mostly I have just used the manual lathe when needing any, not sure why as CNC is much quicker and easier

Turned some 40mm OD 316 down to 3/4" then put an M16 male thread on the end.

It is a fixing for a steering ram and will be welded to the steering rod at some point.

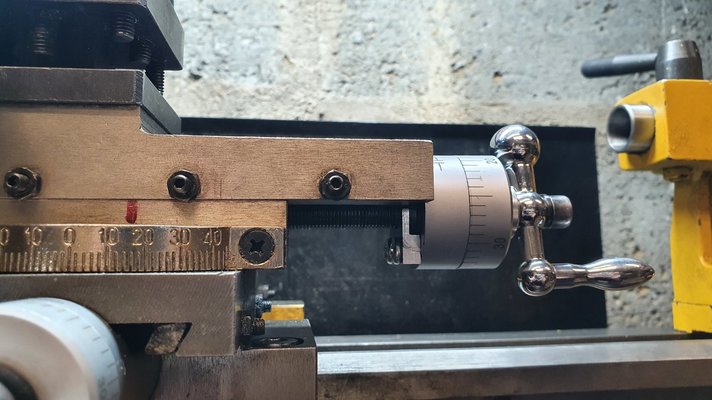

Made a little plate which should hold the topslide screw in place instead of it seizing up the dial on my mini lathe. Quite happy with how it turned out.

Setup with the G clamp was just to stop it from moving when it was completely cut free.

View attachment 327064

View attachment 327077

View attachment 327065View attachment 327066View attachment 327067View attachment 327068View attachment 327069View attachment 327070

Added the part and works beautifully, would recommend for anyone else with this issue.

*edit

Can't get the imgur post to play the vid, you have to click to watch it

MattF

Forum Supporter

- Messages

- 16,978

- Location

- South Yorkshire

Made my wee press better again after I abused it by trying to bend double the thickness with a reduced die, it started pulling up the base plate. So bored and tapped some 10mm steel and welded in place, will be much stronger but I will not overload it so much next time

View attachment 327624

Animal.

Hood

I am obsessed.

- Messages

- 17,478

- Location

- Carnoustie, Scotland

Aye, can't deny that but I have the technology to repair the misfortunes of my animal behaviourAnimal.

MattF

Forum Supporter

- Messages

- 16,978

- Location

- South Yorkshire

Aye, can't deny that but I have the technology to repair the misfortunes of my animal behaviour

That sentence made me think of The six million dollar man.

selectedgrub

Member

- Messages

- 3,346

- Location

- New Zealand

Pair of feet

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,622

- Location

- North Kent, UK

Reminds me of a duck!Pair of feet

Hood

I am obsessed.

- Messages

- 17,478

- Location

- Carnoustie, Scotland

If it walks like a duck, quacks like a duck then... it is one of @selectedgrub creationsReminds me of a duck!

Today I made . . . . . a big mess of a pile of CD's

These are back ups of accounts and document files that although not particularly sensitive I don't want them falling into the wrong hands.

. . . a Microwave makes short work of rendering them unreadable

![IMG_2425[1].JPG IMG_2425[1].JPG](https://www.mig-welding.co.uk/forum/attachments/img_2425-1-jpg.327710/)

![IMG_2426[1].JPG IMG_2426[1].JPG](https://www.mig-welding.co.uk/forum/attachments/img_2426-1-jpg.327711/)

These are back ups of accounts and document files that although not particularly sensitive I don't want them falling into the wrong hands.

. . . a Microwave makes short work of rendering them unreadable

I'll have to admit to being uncertain as to what the problem was? Friction?Added the part and works beautifully, would recommend for anyone else with this issue.

View attachment 327652

*edit

My mini-lathe used to be hard to wind due to friction - I just added a deep-groove ball race to support it and reduce resistance to turning the handle - it can be spun with fingers now, nice and smoothly.

Nick DV

"That's the only name they ever gave me."

- Messages

- 1,673

- Location

- "A long time ago in a galaxy far, far away...."

Stick them on a board, put it in a frame, call it art, hang it in a gallery and you'll make ££££££££££££££Today I made . . . . . a big mess of a pile of CD's

These are back ups of accounts and document files that although not particularly sensitive I don't want them falling into the wrong hands.

. . . a Microwave makes short work of rendering them unreadable

View attachment 327710

View attachment 327711

The compound screw is only restrained on one side so when you turn it clockwise to screw in the dial binds up because of the way it is built so the little plate takes the load instead of the dial.I'll have to admit to being uncertain as to what the problem was? Friction?

My mini-lathe used to be hard to wind due to friction - I just added a deep-groove ball race to support it and reduce resistance to turning the handle - it can be spun with fingers now, nice and smoothly.

This explains it at a

Ah. Exactly why I inserted the deep groove ball race - take the axial load.The compound screw is only restrained on one side so when you turn it clockwise to screw in the dial binds up because of the way it is built so the little plate takes the load instead of the dial.

This explains it at a

Brad93

Member

- Messages

- 18,740

- Location

- Essex, United Kingdom

That lathe is junk. They've literally made zero effort to even match the dovetails together and the gib looks terrible quality.The compound screw is only restrained on one side so when you turn it clockwise to screw in the dial binds up because of the way it is built so the little plate takes the load instead of the dial.

This explains it at a

All wants scraping by the looks of it and a decent gib that actually fits the dovetail making

MysterG

Member

- Messages

- 1,234

- Location

- Wiltshire, UK

I needed a turntable thing, well needed is possibly a bit strong, wanted is probably nearer the mark.

Anyway as usual it had to be made from what I had available, namely some scraps of wood, a 24v motor with gearbox, a PWM controller, and a bearing plate thingy I got from B&Q for a pound years ago as it would come in handy one day.

Everything bodged together with a belt from a Hoover, and mounted in a wooden crate. Oh did I say it has to be able to turn 10kgs or so.

Bit loud and the belt slips occasionally, but for a first attempt/mock up/proof of theory, it's not bad.

Anyway as usual it had to be made from what I had available, namely some scraps of wood, a 24v motor with gearbox, a PWM controller, and a bearing plate thingy I got from B&Q for a pound years ago as it would come in handy one day.

Everything bodged together with a belt from a Hoover, and mounted in a wooden crate. Oh did I say it has to be able to turn 10kgs or so.

Bit loud and the belt slips occasionally, but for a first attempt/mock up/proof of theory, it's not bad.

Mass produced mini lathe, yea it sucks but I'm slowly fixing it. Got angular contact bearings to fit and will attempt to machine some replacement brass gibs that fit as it's so bad you can't use the parting tool without it just rubbing and going blunt lol.That lathe is junk. They've literally made zero effort to even match the dovetails together and the gib looks terrible quality.

All wants scraping by the looks of it and a decent gib that actually fits the dovetail making

I see this lathe as getting onto the "lathe property ladder", might be the equivalent of a council house but it's a start and a means to progress to a better one in the future.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,553

- Location

- Keeler crater

Any lathe is better than no lathe!Mass produced mini lathe, yea it sucks but I'm slowly fixing it. Got angular contact bearings to fit and will attempt to machine some replacement brass gibs that fit as it's so bad you can't use the parting tool without it just rubbing and going blunt lol.

I see this lathe as getting onto the "lathe property ladder", might be the equivalent of a council house but it's a start and a means to progress to a better one in the future.

Might have missed it but what make is the lathe?Added the part and works beautifully, would recommend for anyone else with this issue.

View attachment 327652View attachment 327653

*edit

Can't get the imgur post to play the vid, you have to click to watch it