You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

redlig

Member

- Messages

- 4,111

- Location

- wiltshire uk

Very nice but I feel they will soon show wear through the anodising and then look scruffy.Oh I also had my first go at anodising which came out reasonably well.

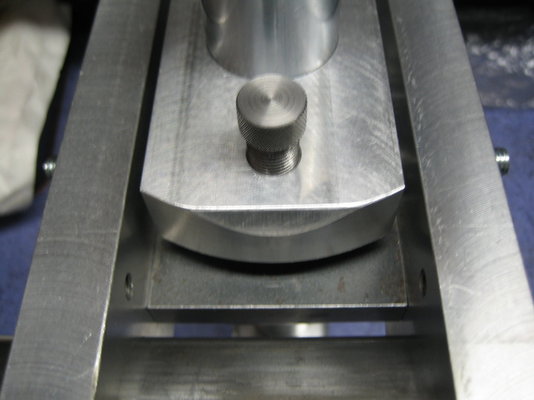

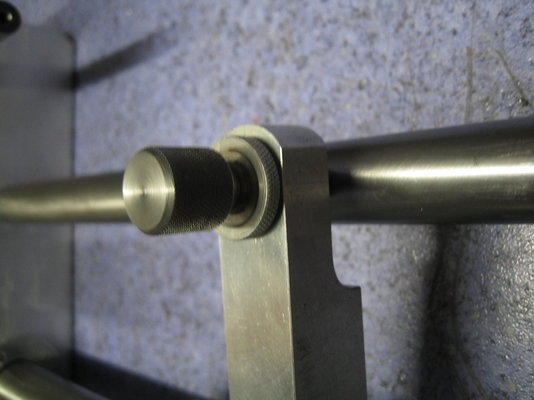

View attachment 334436

I then engraved the side and happy with the results.

View attachment 334437

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

We will see how it works out. Worst comes to the worst I can strip the anodising then just do again, maybe clear, we will see.Very nice but I feel they will soon show wear through the anodising and then look scruffy.

MattF

Forum Supporter

- Messages

- 18,635

- Location

- South Yorkshire

Very nice but I feel they will soon show wear through the anodising and then look scruffy.

I bet a room brightens up when you walk into it.

redlig

Member

- Messages

- 4,111

- Location

- wiltshire uk

It's strange you should say that. 60 years ago a guy at work gave me a piece of card and on it was printed " Your presence has brightened an already dull day" Never did work out what he meant.I bet a room brightens up when you walk into it.

God mode restorations

Member

- Messages

- 8,098

- Location

- uk colchester

Dr.Al

Forum Supporter

- Messages

- 2,779

- Location

- Gloucestershire, UK

Today I made two of these (each slightly different from one another):

Inside that box is all this:

More info: https://www.mig-welding.co.uk/forum/threads/my-latest-project.119708/

Inside that box is all this:

More info: https://www.mig-welding.co.uk/forum/threads/my-latest-project.119708/

northwest

Searching for the Holy Grail.........

- Messages

- 6,718

- Location

- Manchester UK

Well, today was Brownie Points extreme day, I am good for the rest of the year. I am also flat on my back unable to get up. @roofman suggested this three years ago and I owe him. I owe him a kick up the harris, it has nearly killed me. First off, I had no intentions of doing this when I got up this morning. I thought "I will put that bit of flashing up on the edge" and just got carried away. Was a perfect day for it though, Bright with a bit of a chill. Couldn't have wished for better weather really, I suppose it was that more than anything that made me just go for it. Started at ten and flat out until about four thirty, but full blast up and down, back and forth.

The start of it all:

What you doing Dad? Huh? Huh?

It cuts really lovely, she didn't say a word when I rolled it out on the kitchen floor to cut the strips:

Then the flashing at the top, I took Brian's advice and got up there with the leaf blower to blow the dust out of the chase in the stonework, filled it full of" Lead Mate" and beat the flashing in securing it with the correct clips:

It looks absolutely stunning:

I have gone over it carefully with White Spirit and cleaned any Tar or sealer off, I have also carefully straightened out any creases, Edge flashing to make and install on Monday, maybe. I hear you now, what about the flashing at the bottom of the windows, well it is double flashed underneath and well and truly sealed, nothing is getting under it and in ten years when it might consider leaking it will not be my problem.

The start of it all:

What you doing Dad? Huh? Huh?

It cuts really lovely, she didn't say a word when I rolled it out on the kitchen floor to cut the strips:

Then the flashing at the top, I took Brian's advice and got up there with the leaf blower to blow the dust out of the chase in the stonework, filled it full of" Lead Mate" and beat the flashing in securing it with the correct clips:

It looks absolutely stunning:

I have gone over it carefully with White Spirit and cleaned any Tar or sealer off, I have also carefully straightened out any creases, Edge flashing to make and install on Monday, maybe. I hear you now, what about the flashing at the bottom of the windows, well it is double flashed underneath and well and truly sealed, nothing is getting under it and in ten years when it might consider leaking it will not be my problem.

Moose McAlpine

Member

- Messages

- 1,657

- Location

- Norf Lund'n

roofman

Purveyor of fine English buckets and mops

- Messages

- 13,121

- Location

- North West with water on 3 sides

Looks stunning GrahamWell, today was Brownie Points extreme day, I am good for the rest of the year. I am also flat on my back unable to get up. @roofman suggested this three years ago and I owe him. I owe him a kick up the harris, it has nearly killed me. First off, I had no intentions of doing this when I got up this morning. I thought "I will put that bit of flashing up on the edge" and just got carried away. Was a perfect day for it though, Bright with a bit of a chill. Couldn't have wished for better weather really, I suppose it was that more than anything that made me just go for it. Started at ten and flat out until about four thirty, but full blast up and down, back and forth.

The start of it all:

View attachment 334948

What you doing Dad? Huh? Huh?

View attachment 334949

It cuts really lovely, she didn't say a word when I rolled it out on the kitchen floor to cut the strips:

View attachment 334953

Then the flashing at the top, I took Brian's advice and got up there with the leaf blower to blow the dust out of the chase in the stonework, filled it full of" Lead Mate" and beat the flashing in securing it with the correct clips:

View attachment 334956

It looks absolutely stunning:

View attachment 334957

I have gone over it carefully with White Spirit and cleaned any Tar or sealer off, I have also carefully straightened out any creases, Edge flashing to make and install on Monday, maybe. I hear you now, what about the flashing at the bottom of the windows, well it is double flashed underneath and well and truly sealed, nothing is getting under it and in ten years when it might consider leaking it will not be my problem.

will look even better in a couple of years when it takes the "old copper look"

will look even better in a couple of years when it takes the "old copper look"Ali

Member

- Messages

- 1,939

- Location

- Cheshire

That looks great, is it just copper or some special roofing material?Well, today was Brownie Points extreme day, I am good for the rest of the year. I am also flat on my back unable to get up. @roofman suggested this three years ago and I owe him. I owe him a kick up the harris, it has nearly killed me. First off, I had no intentions of doing this when I got up this morning. I thought "I will put that bit of flashing up on the edge" and just got carried away. Was a perfect day for it though, Bright with a bit of a chill. Couldn't have wished for better weather really, I suppose it was that more than anything that made me just go for it. Started at ten and flat out until about four thirty, but full blast up and down, back and forth.

The start of it all:

View attachment 334948

What you doing Dad? Huh? Huh?

View attachment 334949

It cuts really lovely, she didn't say a word when I rolled it out on the kitchen floor to cut the strips:

View attachment 334953

Then the flashing at the top, I took Brian's advice and got up there with the leaf blower to blow the dust out of the chase in the stonework, filled it full of" Lead Mate" and beat the flashing in securing it with the correct clips:

View attachment 334956

It looks absolutely stunning:

View attachment 334957

I have gone over it carefully with White Spirit and cleaned any Tar or sealer off, I have also carefully straightened out any creases, Edge flashing to make and install on Monday, maybe. I hear you now, what about the flashing at the bottom of the windows, well it is double flashed underneath and well and truly sealed, nothing is getting under it and in ten years when it might consider leaking it will not be my problem.

roofman

Purveyor of fine English buckets and mops

- Messages

- 13,121

- Location

- North West with water on 3 sides

Copper foiled backed torch on...very expensive. We used to lay that with hot pour bitumen before torch on felts were around, used wall paper paste on the end of laps to stop spillover of bitumen then just cut and peel it off the paste where it never stuck, this kept the jobs clean. They done Aluminum backed too which you just could not look at in the sun with its reflective property's,had to wear sun glassesThat looks great, is it just copper or some special roofing material?

you're going to have to make the brake lever the same style to matchNot made today but fitted the footpegs that I finished a few days ago.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

There have been thoughts along those linesyou're going to have to make the brake lever the same style to match

. Made some fresh naan this morning too.

. Made some fresh naan this morning too.