DennisCA

Member

- Messages

- 2,048

- Location

- Finland

Dennis

What size stock did you start with for the tongs?

5x25 mm but IMO you should not use this size, they where too thin. 6x25 minimum, 8 or 10mm even better.

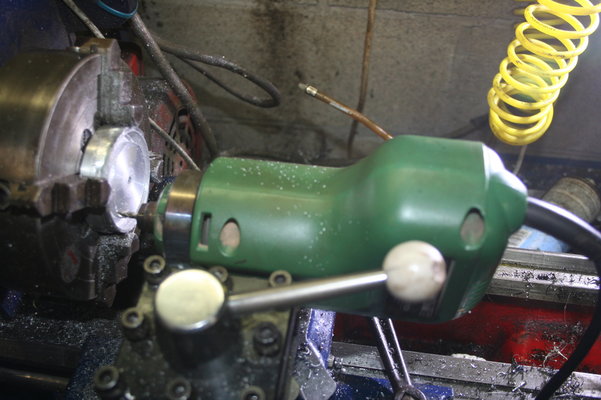

Or 16x16 mm square bar, but then you use a different procedure, I used flat bar and twisted the bits, like this, figured it was an easier method for a beginner: