You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

If it was on 100 mm hard nylon lockable castors you'd have storage space underneath too for strips of flat bar or thin tube .

Oh this is wall mounted above my workbench

Arc Tourist

Member

- Messages

- 4,906

- Location

- Wales

Nice !Handle for my hewing axe is done

Maker

Most folk just call me; Orange Joe

- Messages

- 10,530

- Location

- Keeler crater

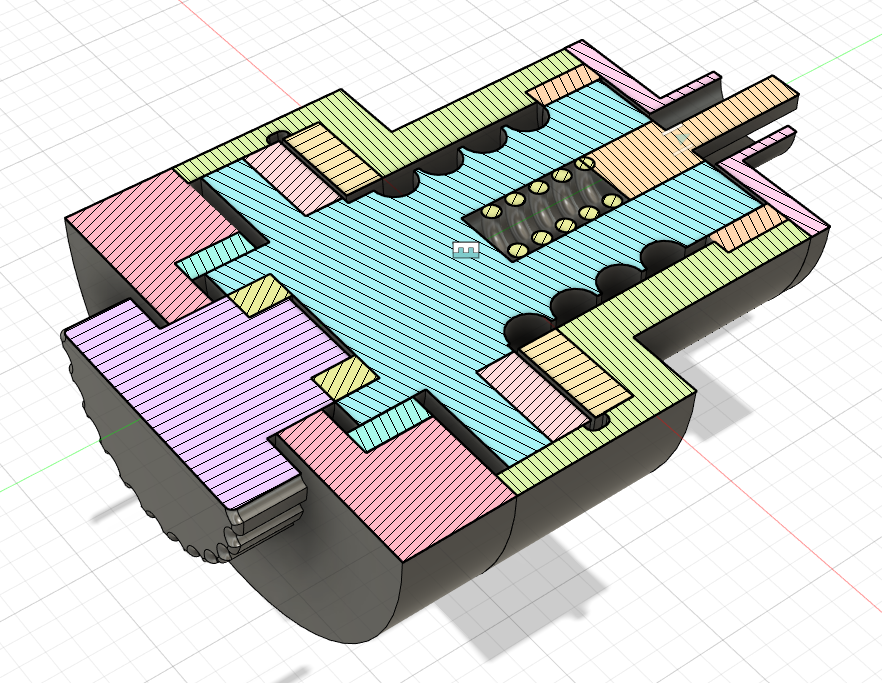

Some people play games when they're bored, apparently I play Fusion 360.  Here's a Kitchenaid coffee grinder attachment.

Here's a Kitchenaid coffee grinder attachment.

Loosely based on an EK43, I'll probably do a revision next time I get bored and then lose interest and almost certainly never build it, but it was a nice bit of procrastination for an hour or so. I've got a half drawn bandsaw model I've lost interest in too.

I've got a half drawn bandsaw model I've lost interest in too.

Here's a Kitchenaid coffee grinder attachment.

Here's a Kitchenaid coffee grinder attachment. Loosely based on an EK43, I'll probably do a revision next time I get bored and then lose interest and almost certainly never build it, but it was a nice bit of procrastination for an hour or so.

I've got a half drawn bandsaw model I've lost interest in too.

I've got a half drawn bandsaw model I've lost interest in too.

Blue Chips

Forum Supporter

- Messages

- 637

- Location

- Maine, USA

I just finished designing and fabricating this trolley for a small OB motor. The angle of the upright frame is adjustable for individual motor positioning. The mounting board can be moved to a higher position to accommodate a long-shaft motor, and the trolley folds up for storage. The basic design is nothing new. I borrowed some ideas from existing motor trolleys that I’ve seen, adding a minor twist of my own here and there. It's pretty hefty, being made of 1-1/4" square tube with 1/8" wall thickness.

I made a few small changes from my original design. For instance, my design used clevis pins and spring cotter pins (aka, hairpins) for locking the adjustable positions, but I found that it was easy to lose the cotters, and they might be difficult for some people to pull out without a needle-nose pliers, so I replaced them with bolts and large four-prong knobs. Now that I’ve tried mounting the motor on the trolley, I think I’d make a couple of other changes, like mounting the trolley handle lower to allow the tiller handle of a short-shaft motor to be fully unfolded to a horizontal position, although that’s a minor thing to me. I might fabricate a removeable bracket or tray for the lower frame, so that I could transport a small portable petrol tank along with the motor.

I was experimenting with a free trial version of Sketchup Pro, and I thought that designing the trolley would be a good excuse to learn to use the software. I also tried a couple of animation and rendering extensions for Sketchup, which worked pretty well. However, I haven’t decided yet if I want to lay out the silver for Sketchup Pro. I recently downloaded the personal-use version of Fusion 360, which I plan to try on a couple of my own projects, and if I like it, I might end up spending the cash for an upgrade.

Here's a rendered animation that I made of my design, made with a couple of Sketchup extensions:

My standard disclaimer: This is an experimental, prototype device. I do not guarantee the safety, efficacy, or applicability of any devices, designs, or ideas that I have described or depicted here. Any use of these devices, designs, or ideas is entirely at your own risk.

I made a few small changes from my original design. For instance, my design used clevis pins and spring cotter pins (aka, hairpins) for locking the adjustable positions, but I found that it was easy to lose the cotters, and they might be difficult for some people to pull out without a needle-nose pliers, so I replaced them with bolts and large four-prong knobs. Now that I’ve tried mounting the motor on the trolley, I think I’d make a couple of other changes, like mounting the trolley handle lower to allow the tiller handle of a short-shaft motor to be fully unfolded to a horizontal position, although that’s a minor thing to me. I might fabricate a removeable bracket or tray for the lower frame, so that I could transport a small portable petrol tank along with the motor.

I was experimenting with a free trial version of Sketchup Pro, and I thought that designing the trolley would be a good excuse to learn to use the software. I also tried a couple of animation and rendering extensions for Sketchup, which worked pretty well. However, I haven’t decided yet if I want to lay out the silver for Sketchup Pro. I recently downloaded the personal-use version of Fusion 360, which I plan to try on a couple of my own projects, and if I like it, I might end up spending the cash for an upgrade.

Here's a rendered animation that I made of my design, made with a couple of Sketchup extensions:

My standard disclaimer: This is an experimental, prototype device. I do not guarantee the safety, efficacy, or applicability of any devices, designs, or ideas that I have described or depicted here. Any use of these devices, designs, or ideas is entirely at your own risk.

Some people play games when they're bored, apparently I play Fusion 360.Here's a Kitchenaid coffee grinder attachment.

View attachment 288649

Loosely based on an EK43, I'll probably do a revision next time I get bored and then lose interest and almost certainly never build it, but it was a nice bit of procrastination for an hour or so.I've got a half drawn bandsaw model I've lost interest in too.

I did a woodchipper once.

I did a woodchipper once.Arc Tourist

Member

- Messages

- 4,906

- Location

- Wales

That's slick !I just finished designing and fabricating this trolley for a small OB motor. The angle of the upright frame is adjustable for individual motor positioning. The mounting board can be moved to a higher position to accommodate a long-shaft motor, and the trolley folds up for storage. The basic design is nothing new. I borrowed some ideas from existing motor trolleys that I’ve seen, adding a minor twist of my own here and there. It's pretty hefty, being made of 1-1/4" square tube with 1/8" wall thickness.

I made a few small changes from my original design. For instance, my design used clevis pins and spring cotter pins (aka, hairpins) for locking the adjustable positions, but I found that it was easy to lose the cotters, and they might be difficult for some people to pull out without a needle-nose pliers, so I replaced them with bolts and large four-prong knobs. Now that I’ve tried mounting the motor on the trolley, I think I’d make a couple of other changes, like mounting the trolley handle lower to allow the tiller handle of a short-shaft motor to be fully unfolded to a horizontal position, although that’s a minor thing to me. I might fabricate a removeable bracket or tray for the lower frame, so that I could transport a small portable petrol tank along with the motor.

I was experimenting with a free trial version of Sketchup Pro, and I thought that designing the trolley would be a good excuse to learn to use the software. I also tried a couple of animation and rendering extensions for Sketchup, which worked pretty well. However, I haven’t decided yet if I want to lay out the silver for Sketchup Pro. I recently downloaded the personal-use version of Fusion 360, which I plan to try on a couple of my own projects, and if I like it, I might end up spending the cash for an upgrade.

View attachment 288507

View attachment 288506

View attachment 288505

Here's a rendered animation that I made of my design, made with a couple of Sketchup extensions:

My standard disclaimer: This is an experimental, prototype device. I do not guarantee the safety, efficacy, or applicability of any devices, designs, or ideas that I have described or depicted here. Any use of these devices, designs, or ideas is entirely at your own risk.

I like the metal wheels too. I don't like plastic wheels.

Blue Chips

Forum Supporter

- Messages

- 637

- Location

- Maine, USA

The EK43 is a serious grinder. Despite being borderline coffeeholics, my wife and I don't have a line item in our budget for a pricey unit like that. We settle for going to a local roasting company and getting a bag or two of freshly ground coffee about once a week. That reminds me that I'm supposed to be looking for a new espresso machine.Loosely based on an EK43, I'll probably do a revision next time I get bored and then lose interest and almost certainly never build it, but it was a nice bit of procrastination for an hour or so.I've got a half drawn bandsaw model I've lost interest in too.

Hood

I am obsessed.

- Messages

- 17,399

- Location

- Carnoustie, Scotland

Last night I was drawing up an outboard engine stand that I am to be making shortly, well it will be 2 that I need to make, not folding so that simplified things and just castors but it is for slightly larger engines, 150HP Yammies.I just finished designing and fabricating this trolley for a small OB motor. The angle of the upright frame is adjustable for individual motor positioning. The mounting board can be moved to a higher position to accommodate a long-shaft motor, and the trolley folds up for storage. The basic design is nothing new. I borrowed some ideas from existing motor trolleys that I’ve seen, adding a minor twist of my own here and there. It's pretty hefty, being made of 1-1/4" square tube with 1/8" wall thickness.

I made a few small changes from my original design. For instance, my design used clevis pins and spring cotter pins (aka, hairpins) for locking the adjustable positions, but I found that it was easy to lose the cotters, and they might be difficult for some people to pull out without a needle-nose pliers, so I replaced them with bolts and large four-prong knobs. Now that I’ve tried mounting the motor on the trolley, I think I’d make a couple of other changes, like mounting the trolley handle lower to allow the tiller handle of a short-shaft motor to be fully unfolded to a horizontal position, although that’s a minor thing to me. I might fabricate a removeable bracket or tray for the lower frame, so that I could transport a small portable petrol tank along with the motor.

I was experimenting with a free trial version of Sketchup Pro, and I thought that designing the trolley would be a good excuse to learn to use the software. I also tried a couple of animation and rendering extensions for Sketchup, which worked pretty well. However, I haven’t decided yet if I want to lay out the silver for Sketchup Pro. I recently downloaded the personal-use version of Fusion 360, which I plan to try on a couple of my own projects, and if I like it, I might end up spending the cash for an upgrade.

View attachment 288507

View attachment 288506

View attachment 288505

Here's a rendered animation that I made of my design, made with a couple of Sketchup extensions:

My standard disclaimer: This is an experimental, prototype device. I do not guarantee the safety, efficacy, or applicability of any devices, designs, or ideas that I have described or depicted here. Any use of these devices, designs, or ideas is entirely at your own risk.

Blue Chips

Forum Supporter

- Messages

- 637

- Location

- Maine, USA

Same here. These are pretty strong wheels, and they came with decent quality sealed bearings.I like the metal wheels too. I don't like plastic wheels.

Hood

I am obsessed.

- Messages

- 17,399

- Location

- Carnoustie, Scotland

Today I made lots of swearing sounds.

These turned up earlier than expected and as some things that were expected hadn't turned up I thought I might as well get on with these.

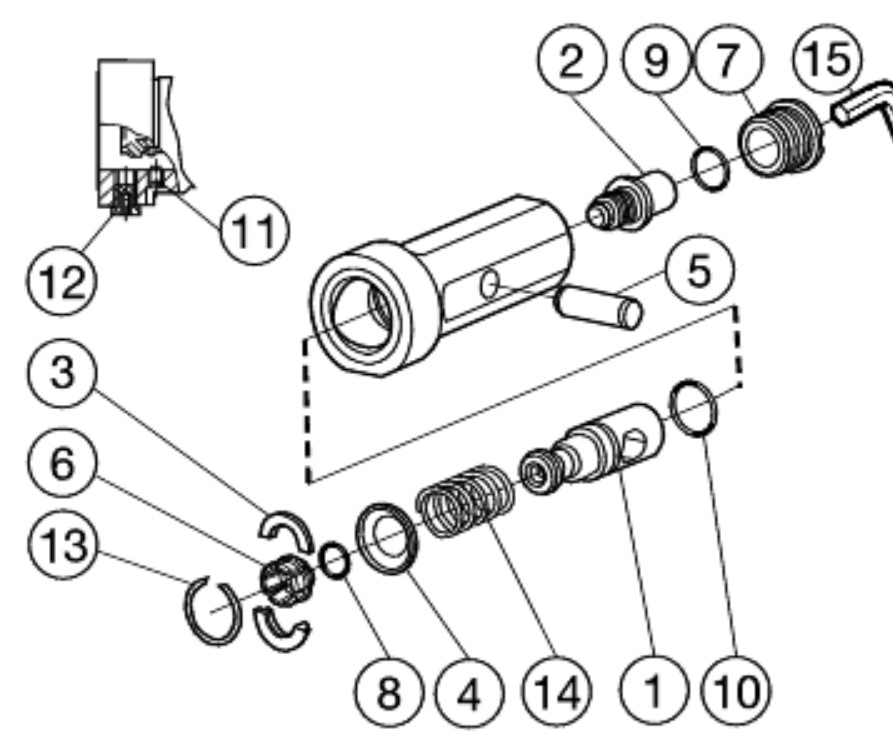

They are segmented grabbers for a Capto tooling block. A real nightmare to fit.

They are No 6 in the below diagram. Trying to get them all held whilst I tried to get the O Ring on, then the split collars and all the time struggling for room due to the dished washer and spring. I would get 4 or so in place then fitting the next one a previous one fell out, took me a couple of hours.

Completed and ready for putting back into the body.

I then hacked up a VDI capto adapter I had made and welded it to a wedge holder, I faced off the wedge holder, some lovely fireworks with that.

Once done I had to mill a circular pocket in the top so I could get the adjuster in.

And fitted to the lathe with a threading bar inserted.

These turned up earlier than expected and as some things that were expected hadn't turned up I thought I might as well get on with these.

They are segmented grabbers for a Capto tooling block. A real nightmare to fit.

They are No 6 in the below diagram. Trying to get them all held whilst I tried to get the O Ring on, then the split collars and all the time struggling for room due to the dished washer and spring. I would get 4 or so in place then fitting the next one a previous one fell out, took me a couple of hours.

Completed and ready for putting back into the body.

I then hacked up a VDI capto adapter I had made and welded it to a wedge holder, I faced off the wedge holder, some lovely fireworks with that.

Once done I had to mill a circular pocket in the top so I could get the adjuster in.

And fitted to the lathe with a threading bar inserted.

Blue Chips

Forum Supporter

- Messages

- 637

- Location

- Maine, USA

The folding feature did make it more complex and required tighter tolerances to make sure that all of the holes lined up in all positions, but indoor space is at a premium at our place, so I try to make things as compact as I can. We have been "boatless" for the past few years (except for our canoe), but that might change this summer, so I might be building a heavier variation on this stand, depending on what kind of powerplant the boat has. I've just been using this small motor to move our floating dock back and forth between our property and the nearest landing when we move the dock in and out of the river for the season.Last night I was drawing up an outboard engine stand that I am to be making shortly, well it will be 2 that I need to make, not folding so that simplified things and just castors but it is for slightly larger engines, 150HP Yammies.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,026

- Location

- France, Brittany.

What's going on in this photo? And what is that tool please ???Today I made lots of swearing sounds.

These turned up earlier than expected and as some things that were expected hadn't turned up I thought I might as well get on with these.

View attachment 288751

They are segmented grabbers for a Capto tooling block. A real nightmare to fit.

They are No 6 in the below diagram. Trying to get them all held whilst I tried to get the O Ring on, then the split collars and all the time struggling for room due to the dished washer and spring. I would get 4 or so in place then fitting the next one a previous one fell out, took me a couple of hours.

View attachment 288750

Completed and ready for putting back into the body.

View attachment 288759

I then hacked up a VDI capto adapter I had made and welded it to a wedge holder, I faced off the wedge holder, some lovely fireworks with that.

View attachment 288760

Once done I had to mill a circular pocket in the top so I could get the adjuster in.

View attachment 288761

And fitted to the lathe with a threading bar inserted.

View attachment 288762

Hood

I am obsessed.

- Messages

- 17,399

- Location

- Carnoustie, Scotland

Just facing off some hardened steel.

pressbrake1

Forum Supporter

- Messages

- 5,556

- Location

- Essex

Blades back from hardening so finish ground on plough grinder (Blanchard)

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,026

- Location

- France, Brittany.

Pretty.Blades back from hardening so finish ground on plough grinder (Blanchard)

View attachment 288769

Maker

Most folk just call me; Orange Joe

- Messages

- 10,530

- Location

- Keeler crater

With a serious price tag to match! It turns out though, a set of 98mm burrs aren't exactly cheap anyway.The EK43 is a serious grinder.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,026

- Location

- France, Brittany.

Burn baby burn, disco inferno.

Memmeddu

Member

- Messages

- 4,948

- Location

- Italia Sardegna

Survived the dentist part 2 ,1st round won

Killed a tooth , next week it will be rebuilt .

I've won the fear of anesthesia and Dremel .

Didn't felt any pain

Once there I was terrified, asked to the dentist to be patient with me because I have no problem with pain because of my kidneys , but a lot with needle .

Once calm down , anesthesia .

He asked I have had allergic reaction to some kind of medicine .

My answer let's find out .

Little bit of panic and struggle for the first minutes then , closed my eyes and shut off the brain or better imagined to be somewhere else doing other .

Come back to the real when he used an instrument heated up to white glow (I presume over 1200°C ) to burn the nerve .

Only moment when I felt something .

Opened my eyes and seen smoke and this thing cherry red .

Overall it's been funny

Hope that next time wouldn't be much different .

It has been a pretty stressful day and that it's only the easy part of it .

Killed a tooth , next week it will be rebuilt .

I've won the fear of anesthesia and Dremel .

Didn't felt any pain

Once there I was terrified, asked to the dentist to be patient with me because I have no problem with pain because of my kidneys , but a lot with needle .

Once calm down , anesthesia .

He asked I have had allergic reaction to some kind of medicine .

My answer let's find out .

Little bit of panic and struggle for the first minutes then , closed my eyes and shut off the brain or better imagined to be somewhere else doing other .

Come back to the real when he used an instrument heated up to white glow (I presume over 1200°C ) to burn the nerve .

Only moment when I felt something .

Opened my eyes and seen smoke and this thing cherry red .

Overall it's been funny

Hope that next time wouldn't be much different .

It has been a pretty stressful day and that it's only the easy part of it .