You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Like a lot. We aren't worthy...Cut a load of bits up in preparation for, hopefully, finishing the hopper tomorrow.

View attachment 320446View attachment 320447View attachment 320448

Welded up the 3 funnels of which one is shown below.

View attachment 320449

Screwdriver

Member

- Messages

- 10,552

View attachment 320465

Another hole just for @Screwdriver

Turned out the insert I'd used was chipped.

I assumed there was something wrong...

I often have trouble with aluminium and carbide inserts, I find HSS gives me much better results. I'd be happy to achieve results like these though, especially considering the scale and resulting magnification.

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

You'll have more luck if it has a light bulb on it.

Quite like the bandy legs

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

Quite apt for a cowboyCouldn't find a straighter horse shoe

I assumed there was something wrong...

I often have trouble with aluminium and carbide inserts, I find HSS gives me much better results. I'd be happy to achieve results like these though, especially considering the scale and resulting magnification.

I think I chipped it running some test bits in stainless a few weeks ago, but the other parts I've been making haven't shown any finish issues until the latest stock.

I had to go and get a mirror to check it, as with the polished inserts and the lighting in the lathe, it's hard to tell from above if the insert is damaged, unless I've managed to completely destroy it.

That was one benefit of the old lathe, I could just spin the turret around to see inserts end-on, but that's a bit harder on something with no turret.

Screwdriver

Member

- Messages

- 10,552

I think I chipped it running some test bits in stainless a few weeks ago, but the other parts I've been making haven't shown any finish issues until the latest stock.

I had to go and get a mirror to check it, as with the polished inserts and the lighting in the lathe, it's hard to tell from above if the insert is damaged, unless I've managed to completely destroy it.

That was one benefit of the old lathe, I could just spin the turret around to see inserts end-on, but that's a bit harder on something with no turret.

I should say the project itself, setting up a CNC lathe, is massively impressive and no doubt full of such hurdles. Have I missed a dedicated thread on it somewhere?

Only thing on here, are a couple photos of it.I should say the project itself, setting up a CNC lathe, is massively impressive and no doubt full of such hurdles. Have I missed a dedicated thread on it somewhere?

It's one I imported from China last year, and is a bit of step up from what it replaced. I can't fault it for what it cost, and I'm only just getting around to expanding what I make on it.

Kram

Member

- Messages

- 7,465

- Location

- Sussex

A thread about it would be an interesting read, and by read, I mean photos.Only thing on here, are a couple photos of it.

It's one I imported from China last year, and is a bit of step up from what it replaced. I can't fault it for what it cost, and I'm only just getting around to expanding what I make on it.

I just need to find some parting inserts more suitable for aluminium

Ive got a few PCD's in dcmt/ccmt, they beat the polished carbide types for finish. Im yet to see any in GTN2 shape or Id buy one, only MGMN shape, but the holders only allow small diameters under 30mm. This sort

2pcs (CK-CNC) MGMN200 PCD for Aluminum Diamond Insert Carbide Bits | eBay

Find many great new & used options and get the best deals for 2pcs (CK-CNC) MGMN200 PCD for Aluminum Diamond Insert Carbide Bits at the best online prices at eBay! Free delivery for many products.

www.ebay.co.uk

MGMN 200 PCD1300 Diamond Grooving Insert for Aluminium Alloys with less than 12% Si content

MGMN 200 PCD1300 Diamond Grooving Insert for Aluminium Alloys with less than 12% Si content.

www.shop-apt.co.uk

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

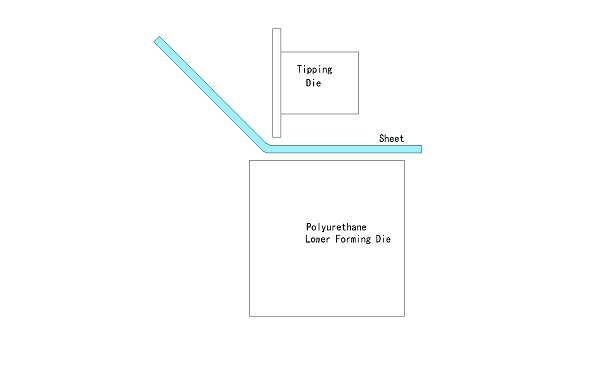

Something that looks a bit like a tipping die for a bead roller.

It's a first go at making one so not sure if my dimensions are suitable as I've just copied it from images off the internet. None of the sellers are daft enought to provide dimensions as they are pretty simple to make. I need a skateboard wheel or some firm plastic to make the part it rolls against. 22mm ID to fit my rollers. The tippy bit is 3mm wide with a bit of a radius done with a file on the lathe. Grub screw is M8 so it matches all my other rollers. It might need a little spacer on the back as the material I used was a bit short. It's not hardened but it only needs to upset 1mm steel or ally sheet so I think it should hold up.

This is what the Chinese will sell to you for about 40 quid.

This is what it does on the bead roller.

It's a first go at making one so not sure if my dimensions are suitable as I've just copied it from images off the internet. None of the sellers are daft enought to provide dimensions as they are pretty simple to make. I need a skateboard wheel or some firm plastic to make the part it rolls against. 22mm ID to fit my rollers. The tippy bit is 3mm wide with a bit of a radius done with a file on the lathe. Grub screw is M8 so it matches all my other rollers. It might need a little spacer on the back as the material I used was a bit short. It's not hardened but it only needs to upset 1mm steel or ally sheet so I think it should hold up.

This is what the Chinese will sell to you for about 40 quid.

This is what it does on the bead roller.

cardiffrob

Member

- Messages

- 1,605

- Location

- Wales, Llantwit Major.