You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

Made a shelf today.

Fine piece of bespoke carpentry.

Wasted in the workshop really, no one else gets to admire it.

Still, keeps the little hydrovane off the floor. Got my old pcl hose reel 're hosed too and mounted that up.

Ordered a few more connection bits as this will have a receiver, regulator and honeywell pressure switch bodged into the set up too.

Only 70psi but so quiet! Saves firing up the big compressor if I don't need to.

Fine piece of bespoke carpentry.

Wasted in the workshop really, no one else gets to admire it.

Still, keeps the little hydrovane off the floor. Got my old pcl hose reel 're hosed too and mounted that up.

Ordered a few more connection bits as this will have a receiver, regulator and honeywell pressure switch bodged into the set up too.

Only 70psi but so quiet! Saves firing up the big compressor if I don't need to.

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

DON'T LEAVE THAT CROWBAR HANGING LIKE THAT !!!!!!! .

It's not it's permanent home, but they normally hang like that. Not fallen off in 8 years.

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

Ouch!famous last words , till it lands blade down on some ones toes. As happened to me many years ago when some one left a crowbar hanging on the header plate of some studwork !

It's only my toes in there and there is a tool box about 12" below it, but point taken.

The smaller ones are now all in my tool box.

They all used to hang on the top of the blockwork in between the roof joists, but uve just filled that with insulation.

Maybe I'll mount a bar on the wall and hang them over that.

James1979

Member

- Messages

- 8,434

- Location

- Orkney

If you can find them, 312’s may help next time you’ve dis similar metals.Used my best (whatever I could find 316 rods), works for me.

Always done it like that.

What do you dislike ?

I'm not a pro, oh no...

Looks good

James1979

Member

- Messages

- 8,434

- Location

- Orkney

Yeah my bad. One of those days309 is what I would use, well if I have any at the time, if not 316 is what I use, usually have them

Hood

I am obsessed.

- Messages

- 17,485

- Location

- Carnoustie, Scotland

I think, and I am saying, think. 312 is usually for higher alloy steels rather than mild steels but...Yeah my bad. One of those days

Tangledfeet

Think outside, no box required.

- Messages

- 3,142

- Location

- Top of a hill above St Andrews, Fife

15 metres of valley gutter in 4 sections. Press brake getting some use recently which is good, I've hardly touched the thing since I re tooled it!

View attachment 320129

That isn't guttering, is it.

'Fess up; it's really a urinal isn't it?

Memmeddu

Member

- Messages

- 5,062

- Location

- Italia Sardegna

One of the happiest day of my life.

First day as apprentice in a machine shop.

I was like child at Legoland

Gantry cranes,lathes,radial arm drill, Bridgeport style mill drill,horizontal milling machines, surface grinders, honing machines, slotting machines,power hacksaw, hydraulic bandsaw, mig ,stick,Tig welders , cutting torches.

That's a dream.

I've done so many things today , working , learning and trying to give everything I could.

Employees and employers happy of me and of my approach to work.

Look , think, ask get done.

Example I know they will soon need a tool ,I ask I they need it , and take it where it's needed.

They made me use a oxy propane torch to cut a dozer blade , and they said me that I wouldn't have much to wait prior to start using a lathe (under their supervision because I've never used one)

Essentially I got to say , today was a good day (cit.)

First day as apprentice in a machine shop.

I was like child at Legoland

Gantry cranes,lathes,radial arm drill, Bridgeport style mill drill,horizontal milling machines, surface grinders, honing machines, slotting machines,power hacksaw, hydraulic bandsaw, mig ,stick,Tig welders , cutting torches.

That's a dream.

I've done so many things today , working , learning and trying to give everything I could.

Employees and employers happy of me and of my approach to work.

Look , think, ask get done.

Example I know they will soon need a tool ,I ask I they need it , and take it where it's needed.

They made me use a oxy propane torch to cut a dozer blade , and they said me that I wouldn't have much to wait prior to start using a lathe (under their supervision because I've never used one)

Essentially I got to say , today was a good day (cit.)

James1979

Member

- Messages

- 8,434

- Location

- Orkney

I am pleased you’ve found something.One of the happiest day of my life.

First day as apprentice in a machine shop.

I was like child at Legoland

Gantry cranes,lathes,radial arm drill, Bridgeport style mill drill,horizontal milling machines, surface grinders, honing machines, slotting machines,power hacksaw, hydraulic bandsaw, mig ,stick,Tig welders , cutting torches.

That's a dream.

I've done so many things today , working , learning and trying to give everything I could.

Employees and employers happy of me and of my approach to work.

Look , think, ask get done.

Example I know they will soon need a tool ,I ask I they need it , and take it where it's needed.

They made me use a oxy propane torch to cut a dozer blade , and they said me that I wouldn't have much to wait prior to start using a lathe (under their supervision because I've never used one)

Essentially I got to say , today was a good day (cit.)

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

One of the happiest day of my life.

First day as apprentice in a machine shop.

I was like child at Legoland

Gantry cranes,lathes,radial arm drill, Bridgeport style mill drill,horizontal milling machines, surface grinders, honing machines, slotting machines,power hacksaw, hydraulic bandsaw, mig ,stick,Tig welders , cutting torches.

That's a dream.

I've done so many things today , working , learning and trying to give everything I could.

Employees and employers happy of me and of my approach to work.

Look , think, ask get done.

Example I know they will soon need a tool ,I ask I they need it , and take it where it's needed.

They made me use a oxy propane torch to cut a dozer blade , and they said me that I wouldn't have much to wait prior to start using a lathe (under their supervision because I've never used one)

Essentially I got to say , today was a good day (cit.)

Great stuff , It's a good feeling doing what you enjoy and interested in

, If your allowed to pics would be cool but alot of places don't like that

, If your allowed to pics would be cool but alot of places don't like thatMick Annick

Forum Supporter

- Messages

- 2,740

- Location

- Burgundy, France (450 miles SE of Somerset)

One of the happiest day of my life.

First day as apprentice in a machine shop.

I was like child at Legoland

Gantry cranes,lathes,radial arm drill, Bridgeport style mill drill,horizontal milling machines, surface grinders, honing machines, slotting machines,power hacksaw, hydraulic bandsaw, mig ,stick,Tig welders , cutting torches.

That's a dream.

I've done so many things today , working , learning and trying to give everything I could.

Employees and employers happy of me and of my approach to work.

Look , think, ask get done.

Example I know they will soon need a tool ,I ask I they need it , and take it where it's needed.

They made me use a oxy propane torch to cut a dozer blade , and they said me that I wouldn't have much to wait prior to start using a lathe (under their supervision because I've never used one)

Essentially I got to say , today was a good day (cit.)

That’s great, really pleased for you Memmeddu

Kram

Member

- Messages

- 7,462

- Location

- Sussex

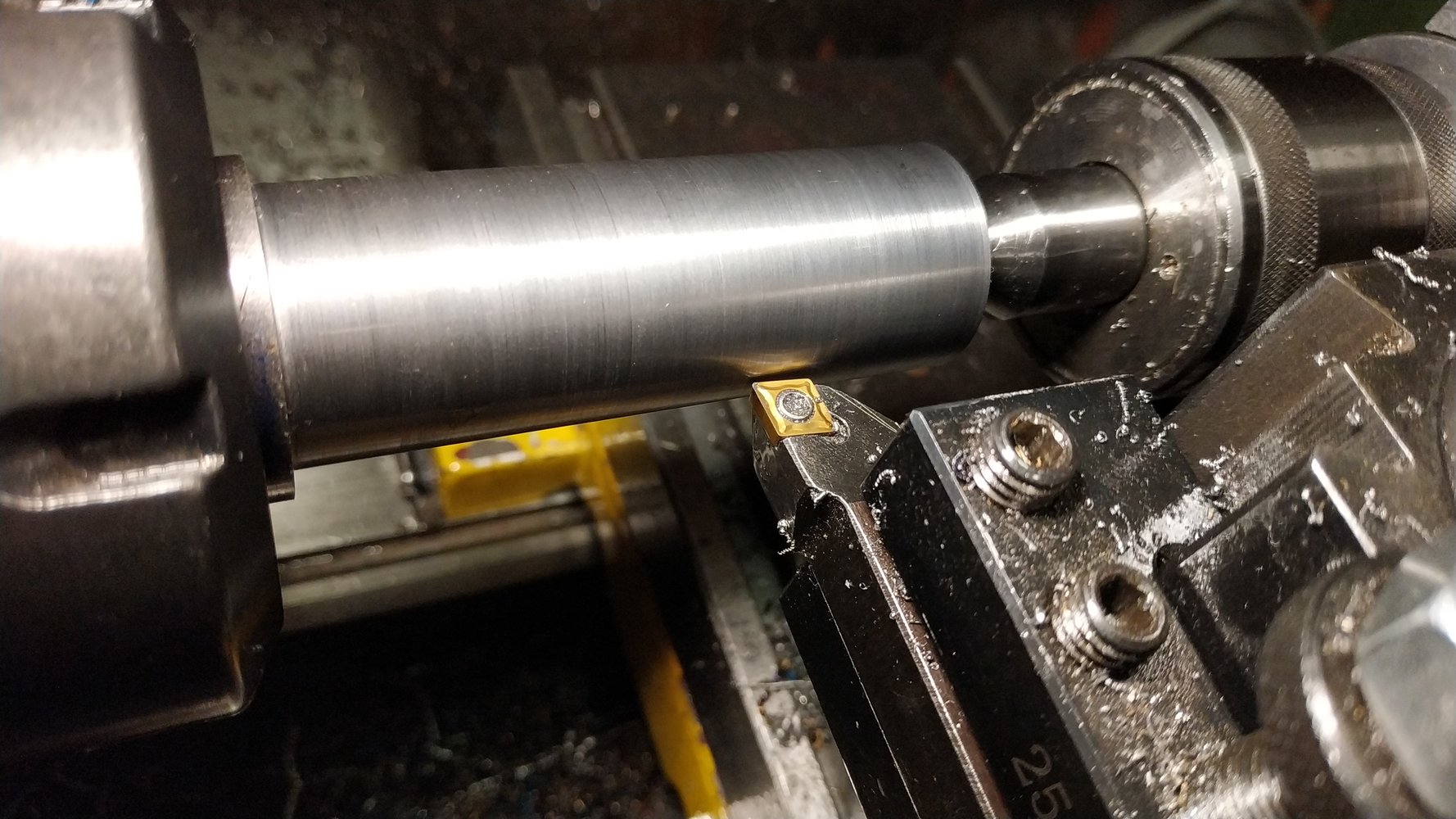

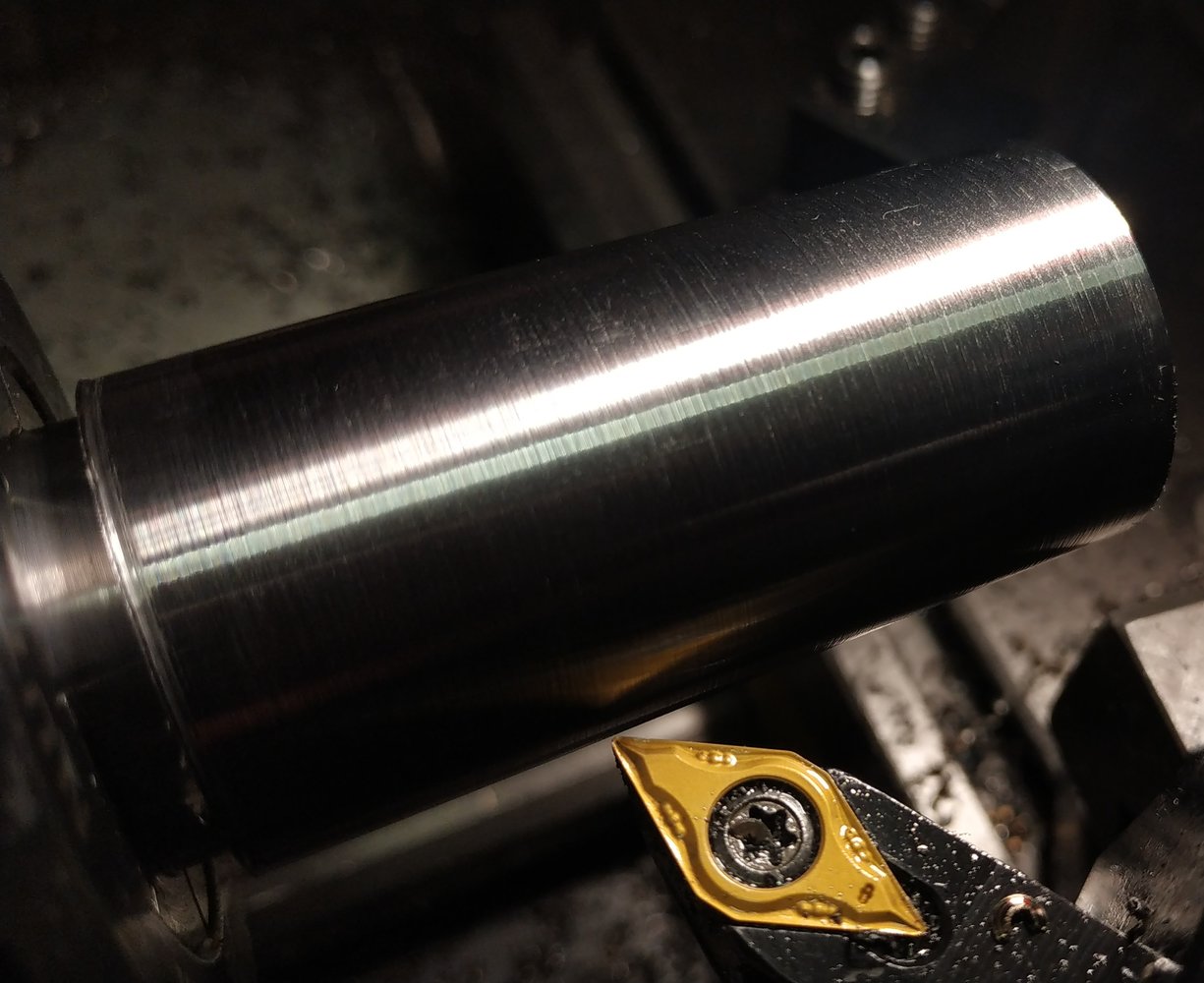

Thanks to @Lewis_RX8 and his lathe thread I have been converted to powerfeeding, only had my lathe 6 years! I set it at 0.092mm/R, the lowest my gears will go. It wasnt anywhere near a mirror finish but probably the smoothest and most consistent I have done on en3b mild. It looks rough but cant feel it.

1mm DoC and 700 rpm. Followed by a 0.05mm dia. pass to get on size. More testing needed..

I know these inserts dont like bigger DoC so swapped a Pramet dcmt. All my packets show 0.1mm/r feed as the minimum so swapped the gears to that. This test was 0.8mm DoC/1.6 dia. Mirror but rougher than the moon. A few more passes and got the roughness down.

Some deflection without the center so needed another very light cut, this is the result before parting.

The problem with these deeper cuts is you hit your final size well before you finish testing!

Too lazy to swap belt for high speed but I think it will be much better at 2200 rpm, but thats still well below half the rated SFM for most inserts on 25mm bar.

Then finshed the loupe. I used the push knurler. How bad could it be on soft mild steel?! Terrible. It just about managed an even print but, very shallow and wont go deeper.

1mm DoC and 700 rpm. Followed by a 0.05mm dia. pass to get on size. More testing needed..

I know these inserts dont like bigger DoC so swapped a Pramet dcmt. All my packets show 0.1mm/r feed as the minimum so swapped the gears to that. This test was 0.8mm DoC/1.6 dia. Mirror but rougher than the moon. A few more passes and got the roughness down.

Some deflection without the center so needed another very light cut, this is the result before parting.

The problem with these deeper cuts is you hit your final size well before you finish testing!

Too lazy to swap belt for high speed but I think it will be much better at 2200 rpm, but thats still well below half the rated SFM for most inserts on 25mm bar.

Then finshed the loupe. I used the push knurler. How bad could it be on soft mild steel?! Terrible. It just about managed an even print but, very shallow and wont go deeper.

Last edited:

NOOOOOOO!!!!!!If your allowed to pics would be cool but alot of places don't like that

Don't get the reputation of a youth of today, always on his phone, this early into the job . . .

Bloke next to you might be okay, but the three down the other end of the shop, seeing the phone out . . .

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

NOOOOOOO!!!!!!

Don't get the reputation of a youth of today, always on his phone, this early into the job . . .

Bloke next to you might be okay, but the three down the other end of the shop, seeing the phone out . . .

I would say it depends if your are keen asking questions and asking if it's okay to take photos for notes or looking back on etc its a good sign quick photo then back to work.

Now sitting there scrolling for five minutes different story but a lot of apprentices here need photos for their qualifications and evidencing as well so not a big deal IMO however like you say maybe could be confused for just sitting on it at a quick glance

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Thanks to @Lewis_RX8 and his lathe thread I have been converted to powerfeeding, only had my lathe 6 years! I set it at 0.092mm/R, the lowest my gears will go. It wasnt anywhere near a mirror finish but probably the smoothest and most consistent I have done on en3b mild. It looks rough but cant feel it.

1mm DoC and 700 rpm. Followed by a 0.05mm dia. pass to get on size. More testing needed..

I know these inserts dont like bigger DoC so swapped a Pramet dcmt. All my packets show 0.1mm/r feed as the minimum so swapped the gears to that. This test was 0.8mm DoC/1.6 dia. Mirror but rougher than the moon. A few more passes and got the roughness down.

Some deflection without the center so needed another very light cut, this is the result before parting.

View attachment 321958

The problem with these deeper cuts is you hit your final size well before you finish testing!

Too lazy to swap belt for high speed but I think it will be much better at 2200 rpm, but thats still well below half the rated SFM for most inserts on 25mm bar

You where hand feeding this whole time , How big are your wrists

Glad it was helpful I tried to post the whole story to my thread from crap finish and no idea to improving it making sure to include the speeds and feeds because pictures not that much help with out them