You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TransTig 2000, a new toy

- Thread starter HughF

- Start date

HughF

Member

- Messages

- 6,469

- Location

- Work: Dorchester, Workshop: Corfe Castle, Wife's place: Frome

Yeah not so bad mate. Should get this pulse remote tested tomorrow now the multicore cable is here, RS royally let me down on that one. The connector I decided on for the board meant I was limited to .5mm2 size cable, surprisingly hard to find a 10 core that wasn't 4 quid a meter.How’s the trans tig treating you Hugh?

Been busy with work, family stuff, about to go to Japan and run a trade show stand, need to retire I think ...

Richard.

Member

- Messages

- 18,344

- Location

- Cambridgeshire

HughF

Member

- Messages

- 6,469

- Location

- Work: Dorchester, Workshop: Corfe Castle, Wife's place: Frome

I'm using it for all my Dc bench work, so that's usually just 1-3mm stainless. It saves me having to fire up a generator and a phase converter to power the Hitachi. My travel machine is the little Paton Ukrainian multiprocess machine that I've set up with a valved 17 and a stubby kit.What do you use the TT for mate. Is that your travel machine or do you now do all your dc stuff with it.

Richard.

Member

- Messages

- 18,344

- Location

- Cambridgeshire

Ah very cool.I'm using it for all my Dc bench work, so that's usually just 1-3mm stainless. It saves me having to fire up a generator and a phase converter to power the Hitachi. My travel machine is the little Paton Ukrainian multiprocess machine that I've set up with a valved 17 and a stubby kit.

It will be a lot more useful once the pulse is in action.

You’ll be spoilt because you won’t be limited to 500hz either.

I remember that day round at mine you got some blinding results with that super fast pulse.

HughF

Member

- Messages

- 6,469

- Location

- Work: Dorchester, Workshop: Corfe Castle, Wife's place: Frome

As you might remember, I've not got Any mains electricity at the farm so being able to weld up thin stainless parts just of the solar/battery/inverter system is a big benefit.

It's nice and quiet with that fan on demand too

It's nice and quiet with that fan on demand too

Richard.

Member

- Messages

- 18,344

- Location

- Cambridgeshire

Yeah that’s the thing. You doing stainless at 1-2 mm is never gonna get that unit up to temp inside to get them fans spinning. You’ll probably never hear it make a peep until you slap a 3.2 electrode in it.As you might remember, I've not got Any mains electricity at the farm so being able to weld up thin stainless parts just of the solar/battery/inverter system is a big benefit.

It's nice and quiet with that fan on demand too

BikeWelder

Member

- Messages

- 37

- Location

- Aberdeen

Hi I'm assuming that the MW2000 is the same as the Castotig 2002!!, could you give me a pinout for the Castotig 7 pin Torch Connection, I've fitted a WP26 torch and only need the trigger pins for on/offI can drop down and then come back up again in 4t, I never use 2t anymore, makes my fingers sore.

I'm not sure how to set it to a straight click up/down, there is a 2t and 4t special mode mentioned in the back menu.

Oh, and inside the case of mine is a mw2000 circuit diagram with the pinouts and description of the torch connection. I'll scan it and upload it to my album.

Thanks

BikeWelder

Member

- Messages

- 37

- Location

- Aberdeen

Thanks Hugh, Think I got it figured Pins 2 and 4 are the trigger for the torch, I have a remote RCT-F Pedal also and the control pins on the pedal are B and D for microswitch and A, E and F for the Potentiometer, don't know how these line up with the 10 pin plug on the machine though, hope you can help with that.Ill sort this tomorrow for you

Kind regards

Alex

BikeWelder

Member

- Messages

- 37

- Location

- Aberdeen

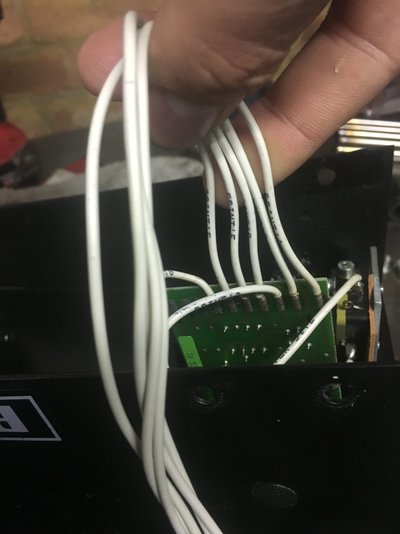

Nope the plug has been removed from the pedal for some reason, these usually come with a plug at either end of the cable with an identical plug on the pedal as fitted to the machine (plastic male 10 pin panel plug) but this one has a cable gland fitted at the Pedal end with the wires soldered directly to the pedal PCB with the wire numbers 1, 2, 3, 4 and 5 connected to the PCB A, B, D, E and F. and no plug on the machine end of the cable.Alex what do you mean by don’t know how they line up on the machine?

Doesn’t the pedal have a plug fitted.

Rgds

Alex

Richard.

Member

- Messages

- 18,344

- Location

- Cambridgeshire

BikeWelder

Member

- Messages

- 37

- Location

- Aberdeen

Thats Great Hugh, Much appreciated thanksI have the exact pedal with proper cable.

I’ll Bell em out and give you pin info later.

Rgds

Alex

Richard.

Member

- Messages

- 18,344

- Location

- Cambridgeshire

I’m not Hugh.Thats Great Hugh, Much appreciated thanks

Rgds

Alex

BikeWelder

Member

- Messages

- 37

- Location

- Aberdeen

Apologies, Thanks RichardI’m not Hugh.

BikeWelder

Member

- Messages

- 37

- Location

- Aberdeen

Can't get that to work, when I switch the machine on the HF starts with the plug connected and there is no response from the machine when the pedal is pressed, do you know if there are any links inside the plug on the machine end of the Pedal cable??There in alphabetical order mate

A on board is A pin on machine plug

B on board is B on plug and so on. Easy.

Rgds

Alex