You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wire speed temperature sensitivity

- Thread starter malcolm

- Start date

rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

No noticeable resistance there to start with, but a new tip with the 0.8 wire made no difference. I normally find the resistance increases when the tip and wire gets hot - can grab if you really heat them up.

I'm thinking more in a change of mechanical resistance as the tip heats up.

malcolm

& Clementine the Cat

- Messages

- 9,818

- Location

- Bedford UK

Good point to try the wire feed independantly. Other thing I'm tempted to do is try swinging the trimmer backwards and forwards to clear any dirt.

Steve gave me the phone number of an engineer at Portamig. Initially couldn't get hold of him, then realised I couldn't define the problem accurately over the phone. Working during the daytime since then.

Thought I'd check on here first to see if it was something obvious. Talking about it on the forum and trying things really helps define the problem.

Steve gave me the phone number of an engineer at Portamig. Initially couldn't get hold of him, then realised I couldn't define the problem accurately over the phone. Working during the daytime since then.

Thought I'd check on here first to see if it was something obvious. Talking about it on the forum and trying things really helps define the problem.

malcolm

& Clementine the Cat

- Messages

- 9,818

- Location

- Bedford UK

Ckecked what happens just feeding wire through without actually welding - it seems to do the same thing, increasing speed about 50% after 10m of wire. Also tried fiddling with the trimmer but that didn't help - might try it again after it's had the chance to cool.

That rules a lot of stuff out. Probably enough information to go to the technical boffins to see what they make of it. Shall keep you posted, and other suggestions are most welcome.

That rules a lot of stuff out. Probably enough information to go to the technical boffins to see what they make of it. Shall keep you posted, and other suggestions are most welcome.

malcolm

& Clementine the Cat

- Messages

- 9,818

- Location

- Bedford UK

That one to the bottom LHS? I have a thermocouple but no temperature readout. It stabilises at about 40 degrees C based on a rough cal using a hot cup of tea.

Nothing else gets noticeably hot to the touch. Haven't got any freezer spray - will try and get hold of some. What are your thoughts there - I've not figured out the circuit (I'm not all that electrically switched on).

Nothing else gets noticeably hot to the touch. Haven't got any freezer spray - will try and get hold of some. What are your thoughts there - I've not figured out the circuit (I'm not all that electrically switched on).

rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

That's the one, I'd be looking at a rise in temperature the longer the motor is run, until it stabilises at the point where the heat dissipated by the heatsink equals the heat generated by the transistor.

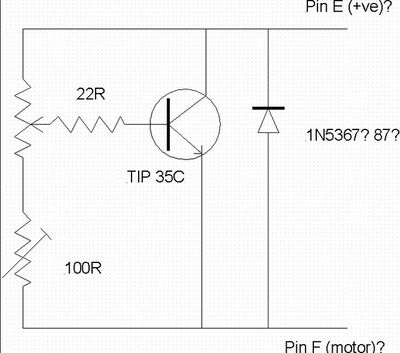

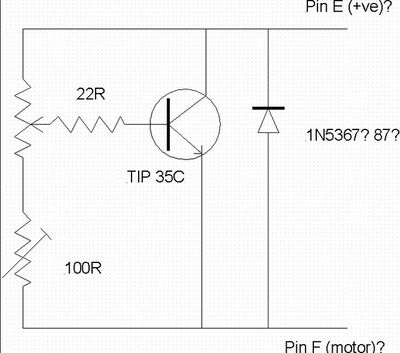

This is the SIP PCB - Yours looks pretty similar

The potentiometer effectively alters the resistance of the transistor, which sets the current going through the motor. This circuit is used because transistors that dissipate heat are smaller and cheaper than wirewound power potentiometers.

The current depends on the resistance, the temperatire depends on the current and the resistance depends on the temperature. Which is nice.

This is the SIP PCB - Yours looks pretty similar

The potentiometer effectively alters the resistance of the transistor, which sets the current going through the motor. This circuit is used because transistors that dissipate heat are smaller and cheaper than wirewound power potentiometers.

The current depends on the resistance, the temperatire depends on the current and the resistance depends on the temperature. Which is nice.

shenion

Tool Pack Rat

- Messages

- 7,586

- Location

- Stone Mountain, GA USA

Malcolm, what is the part # on the transistor? Hope it is something like LM317 (voltage regulator) instead of just a transistor like the SIP's use. Probably a common part.

rtbcomp, that is a variable voltage drop. It sets drops the supply voltage by a fixed amount. It is effected by the gain of the transistor that changes with temperature. Does not regulate the motor voltage well.

rtbcomp, that is a variable voltage drop. It sets drops the supply voltage by a fixed amount. It is effected by the gain of the transistor that changes with temperature. Does not regulate the motor voltage well.

rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

Malcolm, what is the part # on the transistor? Hope it is something like LM317 (voltage regulator) instead of just a transistor like the SIP's use. Probably a common part.

rtbcomp, that is a variable voltage drop. It sets drops the supply voltage by a fixed amount. It is effected by the gain of the transistor that changes with temperature. Does not regulate the motor voltage well.

Exactly, that's what I reckon the problem could be. It's wired in series with the motor, a variable voltage regulator would be much better.

You could make the best of a bad job by increasing the heatsink size or using a small fan to cool it.

malcolm

& Clementine the Cat

- Messages

- 9,818

- Location

- Bedford UK

Strange that it didn't happen from new and that nobody else spotted if it's a design fault. I think something has broken somewhere on my machine.

Here's the transistor. Looked it up - it's a Thyristor - posh! Suggested applications include motor control.

Here's the transistor. Looked it up - it's a Thyristor - posh! Suggested applications include motor control.

Last edited:

- Messages

- 6,344

I have to say malc, If this was one of my machines I would have got the manufacture to sort it, even on the simplest of thing's never mind buggering about with PCBs...Murex sorted me parts FOC even tho, the machine was 10 years old....a simlar story with cebora over an inverter.... Ring em up say its broke, get em to fix it.

malcolm

& Clementine the Cat

- Messages

- 9,818

- Location

- Bedford UK

I have to say malc, If this was one of my machines I would have got the manufacture to sort it, even on the simplest of thing's never mind buggering about with PCBs...Murex sorted me parts FOC even tho, the machine was 10 years old....a simlar story with cebora over an inverter.... Ring em up say its broke, get em to fix it.

Felt it would be a hassle returning the whole thing - would need to post it so need to find a big box and be at home for a day for a transport company to pick it up so a days earnings lost. If I can figure out which bit to ask for I could get that posted here.

Was hoping someone would say it's got to be a bad connection to a certain bit that I could twiddle. But it's interesting to learn about the electrics inside.

- Messages

- 6,344

Felt it would be a hassle returning the whole thing - would need to post it so need to find a big box and be at home for a day for a transport company to pick it up so a days earnings lost. If I can figure out which bit to ask for I could get that posted here.

Thats a fair point. Im lucky the local boys are fairly good, often the main reason for buying something is haveing the dealer on the doorstep.

shenion

Tool Pack Rat

- Messages

- 7,586

- Location

- Stone Mountain, GA USA

Yes, looks like they use pulse-width to control the speed of the motor. I would have expected better for a higher-end machine.Strange that it didn't happen from new and that nobody else spotted if it's a design fault. I think something has broken somewhere on my machine.

Here's the transistor. Looked it up - it's a Thyristor - posh! Suggested applications include motor control.

Thyristors don't like inductive loads like motors. Takes a considerable amount of circuitry to do them well. Looks like the same circuit I saw on one of those Wolf welders

I'ld just replace the board. I would check the brushes first. If they are noisy they can make these circuits unstable.

rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

Yes, looks like they use pulse-width to control the speed of the motor. I would have expected better for a higher-end machine.

Thyristors don't like inductive loads like motors. Takes a considerable amount of circuitry to do them well. Looks like the same circuit I saw on one of those Wolf welders

I'ld just replace the board. I would check the brushes first. If they are noisy they can make these circuits unstable.

Proper PWM is better than linear current control in the motor, especially if it incorporates a feedback loop. Judging by the number of components on the PCB it probably works like a basic drill or vacuum cleaner speed control.

malcolm

& Clementine the Cat

- Messages

- 9,818

- Location

- Bedford UK

I'm sure the motor brushes aren't worn, but wouldn't rule out damage due to under-use. I've hardly had the chance to play with the thing.

What would you suggest for a high end machine? (do include RS part numbers and a circuit diagram and I'll give it a try ). Though do we know what the circuit is? rtbcomp posted a SIP schematic, and the sketches in the manual aren't all that detailed (things just plug into the control unit according to that).

). Though do we know what the circuit is? rtbcomp posted a SIP schematic, and the sketches in the manual aren't all that detailed (things just plug into the control unit according to that).

What would you suggest for a high end machine? (do include RS part numbers and a circuit diagram and I'll give it a try

). Though do we know what the circuit is? rtbcomp posted a SIP schematic, and the sketches in the manual aren't all that detailed (things just plug into the control unit according to that).

). Though do we know what the circuit is? rtbcomp posted a SIP schematic, and the sketches in the manual aren't all that detailed (things just plug into the control unit according to that).rtbcomp

Moderator

- Messages

- 18,573

- Location

- Sheffield UK

Don't use the SIP circuit!

Maplin do a motor control kit that I used for a model aeroplane, but I'd agree with Shenion and change the PCB, or have a chat with the maunfacturers - playing around too much may invalidate the warranty if something else goes wrong.

Maplin do a motor control kit that I used for a model aeroplane, but I'd agree with Shenion and change the PCB, or have a chat with the maunfacturers - playing around too much may invalidate the warranty if something else goes wrong.

malcolm

& Clementine the Cat

- Messages

- 9,818

- Location

- Bedford UK

Don't use the SIP circuit!

To be fair the wire speed control was brilliantly stable and then went wrong fairly suddenly. Suggests broken bit rather than huge design flaw. Sounds like we've diagnosed the problem to the PCB which is good enough as it will fit in an envelope. I'll see if I can't blag one.

shenion

Tool Pack Rat

- Messages

- 7,586

- Location

- Stone Mountain, GA USA

If I was doing a high-end machine I'd use a brushless motor. That way the dial would be in RPM (inches/minute). Speed would be exact, not vary with temperature or voltage, torque high, and no brushes to wear out. It is a single chip to implement.

You can buy geared motors with internal brushless controllers. I have used them. You just supply a 0-5V control voltage to set speed (an another pin sets direction.) Motor and 5V reference and pot to set speed. I'm tempted to put one in my little Clarke.

You can buy motor speed controllers, I have one on my lathe (120V AC/DC motor.) Problem is they are designed for big motors. (1/3 - 5HP) and dont regulate well on this small one (1/6HP)

I did a pump controller for a medical app. Basically a pad with ice water running through it. Pump speed was controlled to keep a constant temperature (they used a bilge pump ). Used PWM and it worked well. Also needed no heat sink as it was efficient. PWM is good as it has high torque at low speeds.

). Used PWM and it worked well. Also needed no heat sink as it was efficient. PWM is good as it has high torque at low speeds.

Maybe I should design a speed controller board. Lots of SIPs could use them

You can buy geared motors with internal brushless controllers. I have used them. You just supply a 0-5V control voltage to set speed (an another pin sets direction.) Motor and 5V reference and pot to set speed. I'm tempted to put one in my little Clarke.

You can buy motor speed controllers, I have one on my lathe (120V AC/DC motor.) Problem is they are designed for big motors. (1/3 - 5HP) and dont regulate well on this small one (1/6HP)

I did a pump controller for a medical app. Basically a pad with ice water running through it. Pump speed was controlled to keep a constant temperature (they used a bilge pump

Maybe I should design a speed controller board. Lots of SIPs could use them

malcolm

& Clementine the Cat

- Messages

- 9,818

- Location

- Bedford UK

Completely as an aside - I love the SIP mods that have been posted on the forum - some really creative stuff there. I'm hoping to bring the information together at some point next year so we can offer a forum super SIP (much like those cat's whiskers radios you would build from plans before you could buy them from China).

Not sure how you'd get around the tiny little motor on the SIP, but apart from that I reckon the building blocks are there with some creative electrics.

Not sure how you'd get around the tiny little motor on the SIP, but apart from that I reckon the building blocks are there with some creative electrics.