Yes! There is a ML7 up for £500 at the mo' - but to be sold without gearbox. So you'd have to hunt one down... & it's 300 miles from here.Rediculous, hasnt even got the screw cutting gear box! Some one must have more money than sense!

- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atlas 10F lathe value

- Thread starter Flowboy

- Start date

Phew! A lot of things to consider... as I wasn't looking for a lathe when it was offered to me I feel I've done ok out of the deal. Had a knackered lathe to mess around on, got to make a few useful things over the years & get chance to buy it. I've known my late mates family for nearly 20 years. The prices I've seen lathes fetch (on ebay) is always higher than I expect or are miles away - not easy to check over. I'm not in the engineering world & have no contacts for old gear at cheap rates. With all the advice I'm getting here it seems the Atlas may be rescuable. Especially having looked at Henricks long term resto' & other dilapidated lathes, seems it can be done.

Gritineye & Ford 34/2 I was thinking along those lines - shimming. Something I've done setting up magnetos for backlash. Just wasn't sure how acceptable this is lathe wise but any improvement over current state has got to be good. I don't like to watch drill bits squirelling about so off-centre =0 (that's eek!) I'm unlikely to be making anything very hi-fi; just the odd bush or spacer. If I could true up a brake drum that'd be good. Last thing was a nylon adaptor for my bro's non-std bathroom basin tap.

we all love a bargain and a cheap one is always so much better, I do think the lathe is rescuable, but you like me want it as cheap as possible. Id still love a look at the tailstock dissmantled. I cant get my head around how low it is and how this may be wear and tear.

Good luck

Stan

I appear to be talking myself into it... Anything's better than having to move it again! Will try & get out to the shed over next few days to look at various suggestions you've all made / take tailstock off Stan / Addjunkie would Timken bearings be worn enough at the back to do that? It would be rattling I would have thought. Babbet might wear but would also rattle. I will inspect.

How do you lock the drive to remove a stuck chuck on the Atlas?

How do you lock the drive to remove a stuck chuck on the Atlas?

penfold

Ambassador plenipotentiary

- Messages

- 2,116

- Location

- Argyll and Bute, God's own country.

This chap's video of dismantling the spindle might be of help; is yours the same as his?

There's also this chap who rebushed his tailstock, but I think that's rather advanced for the OP and needs a mill anyway. if you wind the tailstock ram as far out as it can go, how much can you wobble it about?

There's also this chap who rebushed his tailstock, but I think that's rather advanced for the OP and needs a mill anyway. if you wind the tailstock ram as far out as it can go, how much can you wobble it about?

Gareth J

Member

- Messages

- 3,668

- Location

- North Cornwall

I think it's worth checking the bores of the tailstock and headstock are more or less parallel before you try shimming. See if you can get two solid, straightish things clamped in both the chuck and tailstock. maybe two 6-8" lengths of the same bit of bright mild steel. Get them close to each other and put a straight edge across them to inspect how they are misaligned.

Not the most accurate but seeing as the chuck is stuck and the misalignment is pretty large, you should be able to see if anything is miles out. If somehow the bed is on the wonk or the whole tailstock is angling down, shimming it up wont work.

Not the most accurate but seeing as the chuck is stuck and the misalignment is pretty large, you should be able to see if anything is miles out. If somehow the bed is on the wonk or the whole tailstock is angling down, shimming it up wont work.

Great thanks folks & gaz1 - the practical machinist one was the 1st thing I found last week but haven't tried yet, partic' as it is for a different lathe. Just getting as much advice as poss. before I start wielding sledge hammers. Not... Penfold - headstock vid was handy & easily within my pay grade. Also the Atlas mods was interesting with some useful pointers but such refinements will have to wait awhile. If they don't accept my offer then I wont have a lathe to work on. Will be asking instead for opinions on various affordable alternatives...

Gritineye

Member

- Messages

- 2,101

Before using any brute force you may be able to remove the chuck body from the backplate by undoing the fixings at the back.

Be sure to put a piece of ply or similar on the bed ways to protect them before you start work as the chuck will be surprisingly heavy!

This should enable you to get penetrating oil (not WD40) right onto the threads, apply often over a day or so then use some heat on the back plate to expand it, then use a lever fixed on by using the bolt holes.

Be very careful if you decide to lock the spindle, don't use any of the pulleys or gears as being made of Zamak as they will break, much better to try another method first.

I've had good results by fixing a strong flat bar across the backplate (holes drilled in it to use the bolt holes) then with the V belt in the l/h pulley grooves, hold the big countershaft pulley by both hands and sharply turn it away from you so that the lever strikes against a 10" length of 4 x 2 or bigger timber stood on end beside back of the lathe bed. This eliminates the possibility of damaging anything and delivers quite a big shock.

Best to creep up on these things,

Good luck.

Bernard

Be sure to put a piece of ply or similar on the bed ways to protect them before you start work as the chuck will be surprisingly heavy!

This should enable you to get penetrating oil (not WD40) right onto the threads, apply often over a day or so then use some heat on the back plate to expand it, then use a lever fixed on by using the bolt holes.

Be very careful if you decide to lock the spindle, don't use any of the pulleys or gears as being made of Zamak as they will break, much better to try another method first.

I've had good results by fixing a strong flat bar across the backplate (holes drilled in it to use the bolt holes) then with the V belt in the l/h pulley grooves, hold the big countershaft pulley by both hands and sharply turn it away from you so that the lever strikes against a 10" length of 4 x 2 or bigger timber stood on end beside back of the lathe bed. This eliminates the possibility of damaging anything and delivers quite a big shock.

Best to creep up on these things,

Good luck.

Bernard

addjunkie

Member

- Messages

- 13,588

- Location

- Northumberland. Reet oot in the sticks

Have you got a piece of decent round dar, ground, or something machined round like the handle in the bits and bobs pictures. As long as possible.

Stick it in the chuck. Put a clock on it, run along its length, see if its lying up hill, down hill or to the side, rotate chuck by hand, see what happens.

Stick it in the chuck. Put a clock on it, run along its length, see if its lying up hill, down hill or to the side, rotate chuck by hand, see what happens.

gaz1

Member

- Messages

- 20,088

- Location

- westyorkshire

either your returning it or your looking at another one ?Looks like Saturday has been mapped out for me!

MattF

Forum Supporter

- Messages

- 17,592

- Location

- South Yorkshire

Seems funny to think that such a big chunk of metal could be made to distort but it is heavy.

It's easier than you'd think. It's always surprising to see how just nipping a bolt up can cause something which looks so solid to warp. That's why I clamp a piece of rod in the headstock chuck and then set the DTI up on the saddle/cross-slide against that rod, when bolting down. The slightest amount of induced twist anywhere will show as deflection on the DTI.

One way to bolt a unit down without inducing twist is to bolt it down firmly at the headstock end and then just do any other bolts finger tight. That way it's not moving about but you have it somewhat floating .

With regard removing the chuck, I've used this method in the past. You could quite easily use this wooden clamp method on the back end of the spindle where the gear goes though, if you're not disassembling the headstock. The wood gives you something proper to hold to lock the spindle in place somehow, whilst you try working the chuck loose.

penfold

Ambassador plenipotentiary

- Messages

- 2,116

- Location

- Argyll and Bute, God's own country.

I'd do that, but float the tailstock end on epoxy or polyester resin thickened with balloons or colloid; then tighten down once it's set.One way to bolt a unit down without inducing twist is to bolt it down firmly at the headstock end and then just do any other bolts finger tight. That way it's not moving about but you have it somewhat floating .

Useful info re setting bed, thanks.

1st piece of good news is... I've just been given the Lathe! Wasn't expecting that so I'm going to send them a cheque anyway.

2nd is... I got the chuck off! Thanks Gaz1, I used the spin it back against a block of wood method. Boy did it take a lot of whacks to finally crack it, like 100+.

Was a fair bit of crap in there. Threads in chuck are pretty poor but headstock looks good. Cleaned 'em up but screwing back on the whole thing felt loose on headstock thread until it was tight against the stop. I put a bar in & couldnt feel any play in the headstock.

Took tailstock off - how is the base attached to the top? Some kind of hidden screws or dowels? Funnily enough there was a base sold on ebay this a.m. for £4.99. Would have been handy.

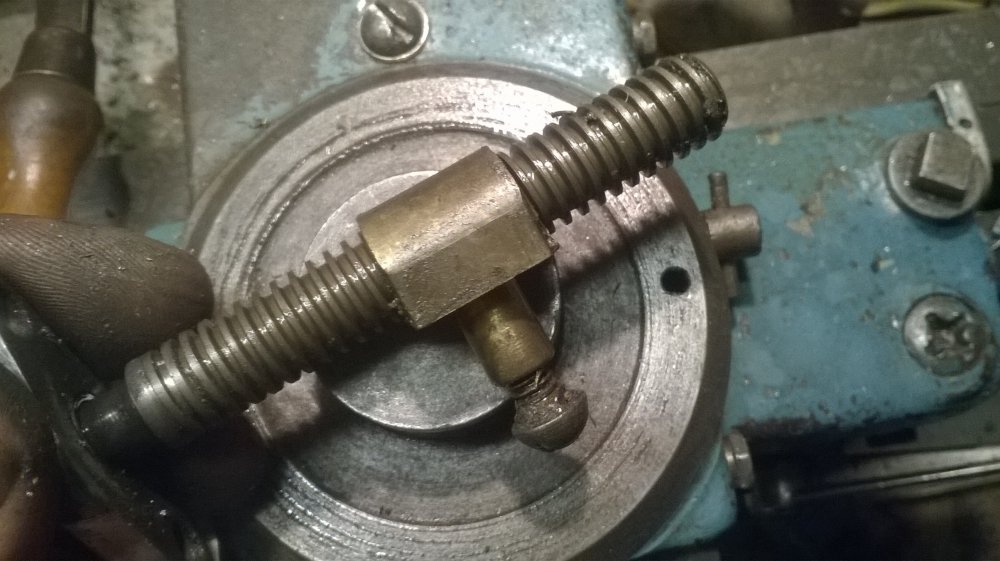

Stripped down compound rest & the bronze screw nut is very sloppy & needs replacing methinks. Screw is worn also; thread width is thinner in central area than at ends by about 10 thou'. A bit tricky to measure.

Oh, & the compound rest has crack damage

1st piece of good news is... I've just been given the Lathe! Wasn't expecting that so I'm going to send them a cheque anyway.

2nd is... I got the chuck off! Thanks Gaz1, I used the spin it back against a block of wood method. Boy did it take a lot of whacks to finally crack it, like 100+.

Was a fair bit of crap in there. Threads in chuck are pretty poor but headstock looks good. Cleaned 'em up but screwing back on the whole thing felt loose on headstock thread until it was tight against the stop. I put a bar in & couldnt feel any play in the headstock.

Took tailstock off - how is the base attached to the top? Some kind of hidden screws or dowels? Funnily enough there was a base sold on ebay this a.m. for £4.99. Would have been handy.

Stripped down compound rest & the bronze screw nut is very sloppy & needs replacing methinks. Screw is worn also; thread width is thinner in central area than at ends by about 10 thou'. A bit tricky to measure.

Oh, & the compound rest has crack damage

off to pub now for last minute celebratory snifter

off to pub now for last minute celebratory snifter