You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knife making , Suitable steel ?

- Thread starter Lewis_RX8

- Start date

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Bit too late for angle grinder now but ready for it

5mm rod for the handle pins

Got quite a few bits of scrap oak balustrade was thinking what nice hard woods I had for handles so tried a bit of beeswax on it seems alright will try some other types, suppose you can always rehandle a knife if I get sick of what I put on it.

5mm rod for the handle pins

Got quite a few bits of scrap oak balustrade was thinking what nice hard woods I had for handles so tried a bit of beeswax on it seems alright will try some other types, suppose you can always rehandle a knife if I get sick of what I put on it.

Screwdriver

Member

- Messages

- 10,519

I think you will find with that design, it should have a very subtle curve all the way along the spine. Makes a huge difference to the look...

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

I think you will find with that design, it should have a very subtle curve all the way along the spine. Makes a huge difference to the look...

Ah yes I made the mistake of only adding a drop point at the end but it does definitely taper down , Good spot

Thought I would keep updating to get some more eyes looking for what I never noticed

Screwdriver

Member

- Messages

- 10,519

Doesn't look that much of a curve.

...but it is.

If you leave it straight, it will look "wrong" even if you can't put your finger on why. The annoying thing is, it will subtract a fair bit of blade width and reduce the possibility of having a deep ricasso from relatively narrow stock.

...but it is.

If you leave it straight, it will look "wrong" even if you can't put your finger on why. The annoying thing is, it will subtract a fair bit of blade width and reduce the possibility of having a deep ricasso from relatively narrow stock.

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Bevels under attack today

Made one bit slightly too high but hopefully be able to file.out that and the imperfections, just to make it look nicer as i don't imagine it'll effect the way the knife works as a tool lol

Quite happy with how close I am to the scribe line in the center however didn't want to go all the way up to the edge with angle grinder for fear of cocking it up so going to do the finishing with a file

Made one bit slightly too high but hopefully be able to file.out that and the imperfections, just to make it look nicer as i don't imagine it'll effect the way the knife works as a tool lol

Quite happy with how close I am to the scribe line in the center however didn't want to go all the way up to the edge with angle grinder for fear of cocking it up so going to do the finishing with a file

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Cheers it's about 6.5mm thick so yes quite a thick bladeLooks good, how thick is the stock you started with? Looks thick, you might want to take the bevels up higher so it's not such a stout edge if it is as thick as it looks.

Do you normally bevel all the way up to the top ridge or leave a bevel line like I have done , I think it's about 14mm from the blade to edge of bevel which I suppose is it going from 0mm to 6.5mm thickness

h-dom

Member

- Messages

- 593

- Location

- Lincs

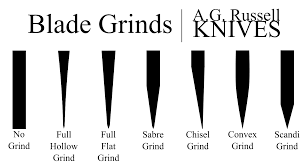

That's a thick spine. On something that thick I would go full flat grind. You can see why below, you will get a better slicer. It will be more like an axe edge like that I would think with such a thick spine.

You don't need to go all the way to the top but if it was me I would go pretty close. More work but hopefully you will get a more useable knife when you're done.

When I first started I made the mistake of making really thick knives which were obviously strong but just weren't good at cutting. Now I try to make them max 4mm thick spine for that size knife. I realise that's no use to you because the stock you have is 6.5mm but doing a higher grind will make it better.

You don't need to go all the way to the top but if it was me I would go pretty close. More work but hopefully you will get a more useable knife when you're done.

When I first started I made the mistake of making really thick knives which were obviously strong but just weren't good at cutting. Now I try to make them max 4mm thick spine for that size knife. I realise that's no use to you because the stock you have is 6.5mm but doing a higher grind will make it better.

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Brilliant cheers I will got for the full flat type grindThat's a thick spine. On something that thick I would go full flat grind. You can see why below, you will get a better slicer. It will be more like an axe edge like that I would think with such a thick spine.

You don't need to go all the way to the top but if it was me I would go pretty close. More work but hopefully you will get a more useable knife when you're done.

When I first started I made the mistake of making really thick knives which were obviously strong but just weren't good at cutting. Now I try to make them max 4mm thick spine for that size knife. I realise that's no use to you because the stock you have is 6.5mm but doing a higher grind will make it better.

View attachment 349775

I suppose I could also grind down flat on the stock just to make it thinner overall but not sure if that's a good idea

h-dom

Member

- Messages

- 593

- Location

- Lincs

Unless you have a mill or surface grinder I wouldn't grind it flat to thin it out.Brilliant cheers I will got for the full flat type grind

I suppose I could also grind down flat on the stock just to make it thinner overall but not sure if that's a good idea

You have plenty of steel to play with, don't expect it to come out perfect on your first knife!! I've made probably a hundred and still have a way to go.

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

I've got a mill so could try it but this is a chopper bushcraft type knife not going to be slicing tomatoes ultra thin lolUnless you have a mill or surface grinder I wouldn't grind it flat to thin it out.

You have plenty of steel to play with, don't expect it to come out perfect on your first knife!! I've made probably a hundred and still have a way to go.

To be honest I'm actually preferring the look of this deeper grind aswell I really like it

Great fun

magnet

Member

- Messages

- 1,354

Looking great that mateI've got a mill so could try it but this is a chopper bushcraft type knife not going to be slicing tomatoes ultra thin lol

To be honest I'm actually preferring the look of this deeper grind aswell I really like it

View attachment 349791

Great fun

Screwdriver

Member

- Messages

- 10,519

Looking good. Biggest mistake I made with mine is going too thin before heat treatment. Ideally you want to leave it pretty thick and even keep a lump on the tip to stop that burning out. depending how much you like grinding, probably 10-20 thou at the cutting edge. Otherwise the thin parts overheat before the entire blade gets up to temperature and the edge can decarburise. Had that happen with a kiridashi and I had to grind the whole tip off. Next time I'll leave the very tip really chunky and finish grind that to shape once its hardened.

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Oops may be a bit thin hereLooking good. Biggest mistake I made with mine is going too thin before heat treatment. Ideally you want to leave it pretty thick and even keep a lump on the tip to stop that burning out. depending how much you like grinding, probably 10-20 thou at the cutting edge. Otherwise the thin parts overheat before the entire blade gets up to temperature and the edge can decarburise. Had that happen with a kiridashi and I had to grind the whole tip off. Next time I'll leave the very tip really chunky and finish grind that to shape once its hardened.

I'll make sure to watch it when I'm heating it up and there is plenty thickness of spine behind it which hopefully will help but can always grind it down some.more

Just measuring my thinnest parts at about 20 thou actually hopefully I'll be okay

Both sides beveled with the angry grinder , following Walter sorrels and how he makes his technique with trying to keep your hands into your body then move the hips back and forth to keep a nice pattern , now to clean up with a file

Screwdriver

Member

- Messages

- 10,519

If I was being cheeky, I'd recall Walter being one of the few "big name" bladesmiths whose blade snapped in half during Forged in Fire.

Luckily, I'm not that mean...

Luckily, I'm not that mean...

With a 6.5mm steel and a bevel height of 14mm you’re about 13 degrees per side (dps) so 26 degrees overall. That’s a fairly good angle for bushcraft/woodwork. I grind my kitchen knives at about 5 dps but wouldn’t be confident using one of them for battoning.

The grind you have looks good, aim for at least 0.5mm on the edge, and try to keep the grinds symmetrical to help with straightness in the HT.

The grind you have looks good, aim for at least 0.5mm on the edge, and try to keep the grinds symmetrical to help with straightness in the HT.

Lewis_RX8

Member

- Messages

- 1,574

- Location

- Scotland

Think nearly ready for heat treat

Emery clothed out most of the scratch's from flap disk and angry grinder , thinking I will sand blast where the handle scales will go after heat treat to give the epoxy a good surface to key to

Was using the file to finish off these sections by the choil as I couldn't quite get in wih the grinder , file marks are a pain to try and sand out got most of them

Found some 8mm thick walnut I believe wood for the scales , bit of IPA to see what it's like with oil applied and think it'll look nice , not mega fancy but works for me

Cheers for all the advice so far folks

Emery clothed out most of the scratch's from flap disk and angry grinder , thinking I will sand blast where the handle scales will go after heat treat to give the epoxy a good surface to key to

Was using the file to finish off these sections by the choil as I couldn't quite get in wih the grinder , file marks are a pain to try and sand out got most of them

Found some 8mm thick walnut I believe wood for the scales , bit of IPA to see what it's like with oil applied and think it'll look nice , not mega fancy but works for me

Cheers for all the advice so far folks