grib

Member

- Messages

- 60

- Location

- Holmfirth

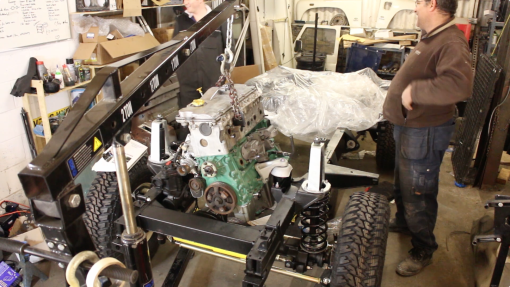

This week, we've been mainly working on our engine, as well as inspecting the rear tub.

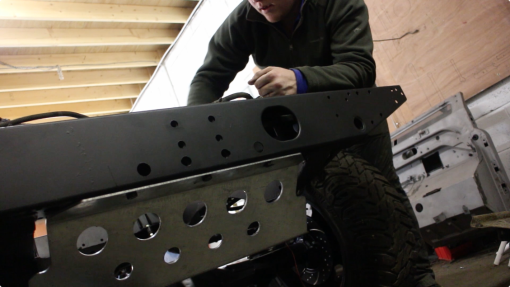

It's a good idea to get the tub sat on an body painting trestle. These can be found on eBay pretty reasonably. They give you really good access to the underside and as an added bonus, fold away when not needed.

The inside of the tub has accumulated a lot of grime from the workshop and so it needed a good clean out. We used a strong road and traffic film remover to strip away any oils that might have been on the surfaces of the tub.

After cleaning, the body mappings have revealed some rust, not to worry, these are going to be blasted and then galved.

There are a lot of holes left in the tub. We'll try alloy brazing to fill them in.

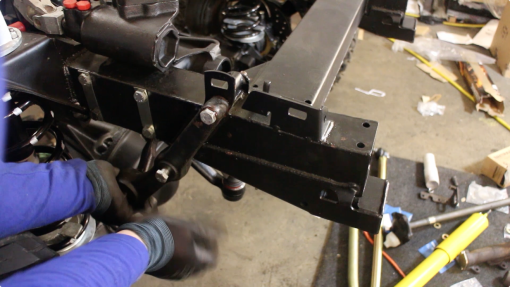

This seat belt mounting bracket is corroded, fortunately YRM metal solutions produces laser cut reproduction panels that we can simply rivet on. The part isn't too expensive either!

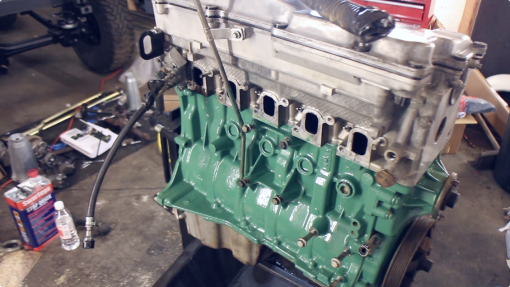

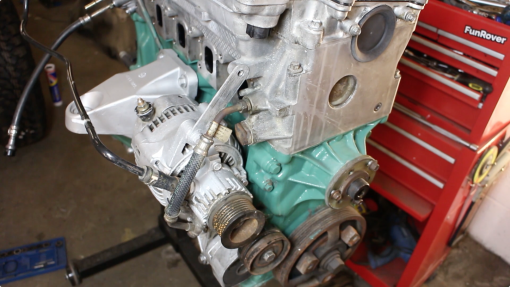

Use a TD5 / V8 Viscous fan set from FlatDog UK we removed the viscous fan in preparation for cleaning and painting the engine.

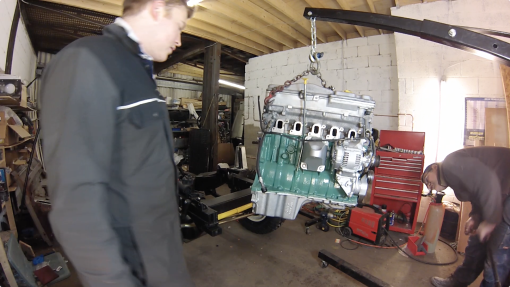

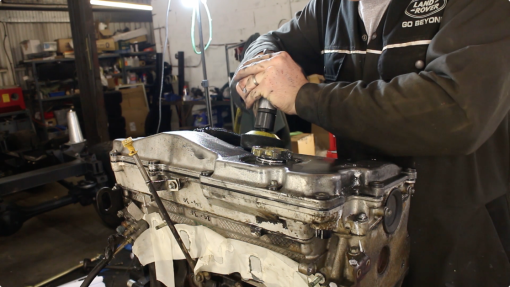

Using a 75mm air polisher and white diamond metal polish and sealer. Why are we polishing the rocker cover? Well, we're not refitting the acoustic cover on the engine, so we want it to look as good as the rest of the vehicle.

Here's a before and part way through, the White Diamond polish is great, it takes very little effort to get to the finish on the right. A few more passes and we'll have a chrome like finish that is protected from further oxidisation thanks to the sealer in the polishing compound.

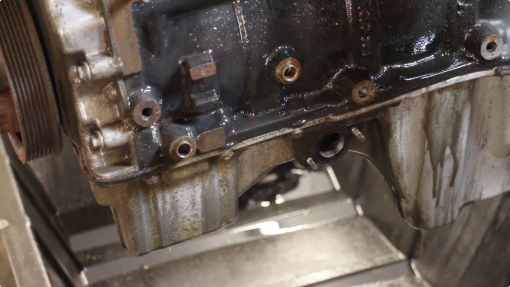

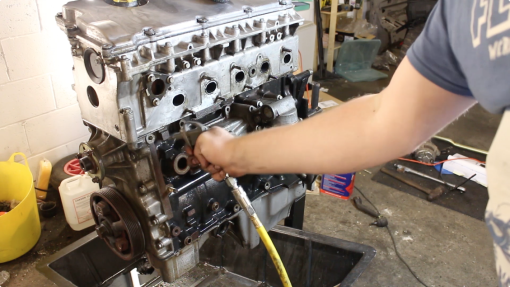

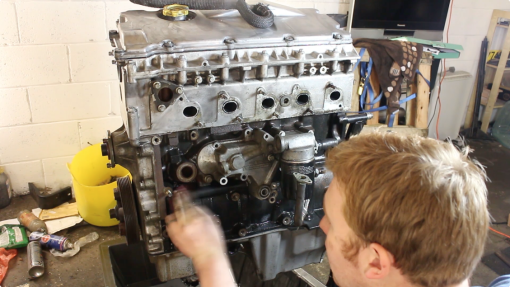

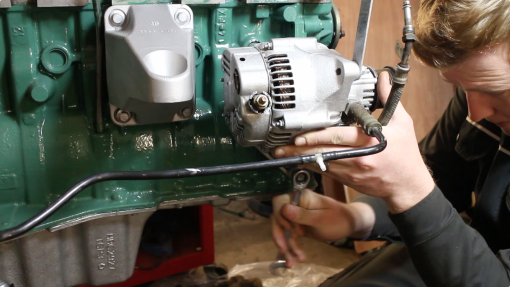

Then we moved onto cleaning the engine, which had a lot of baked on oils, carbon deposits, mud and corrosion.

First, it was given a thorough scrub down with some small stainless steel wire brushes and a degreasing detergent.

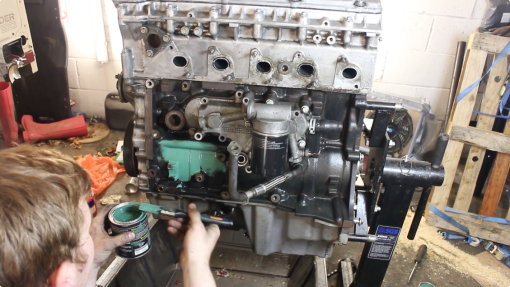

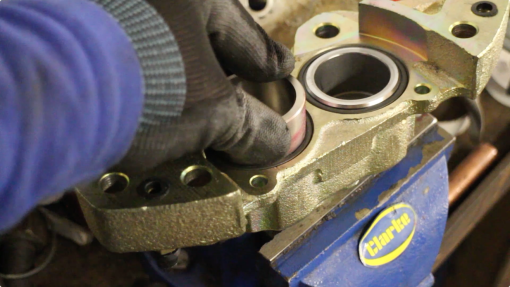

Once dry, we could then tackle the corrosion. Here we're working the corroded areas with the brush more, before switching to a dremel with a wire cup.

Areas such as the end of the block were pretty corroded so it was knocked back with a red scotchbrite pad, polished and then sealed.

Still a little more corrosion that was removed with a flapper wheel on the dremel.]