grib

Member

- Messages

- 60

- Location

- Holmfirth

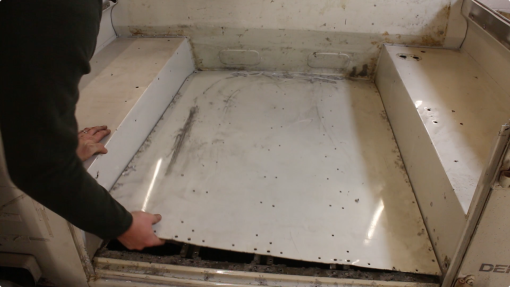

The rear tub is in need of some minor repairs. The tub cappings will be removed and sent off for galvanising. Everywhere else, we have replacement repair sections.

Using a 6mm drill bit, we're drilling into the rivet head, which typically shears off.

Then the crush section of the rivet can be tapped out, this is the quickest way to remove rivets.

There are quite a number of rivets all told on the cappings

In addition to rivets, the cappings are typically held on with some mild adhesives / foam tape and can then be lifted away. Those will be going to the galvanisers along side the bulkhead and will be fitted unpainted to the 90 for that classic Land Rover appearance.

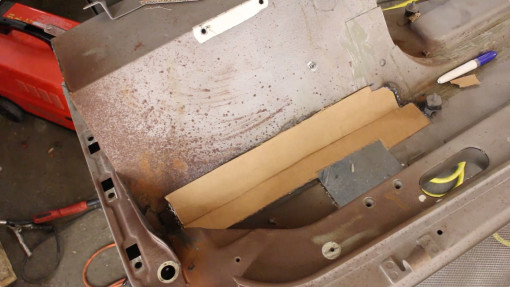

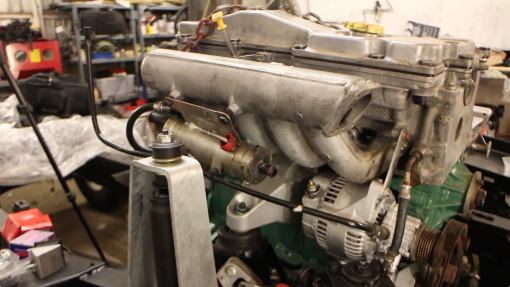

Cappings gone, you can see the Zinc Phosphate primer applied at the factory. Over the primer, the tub is currently overcoated in 2 pack (Chawton White). We'll be going to the classic (and now rather popular) Pastel Green, a Series 1 colour

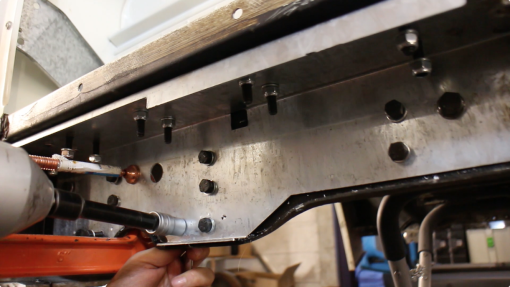

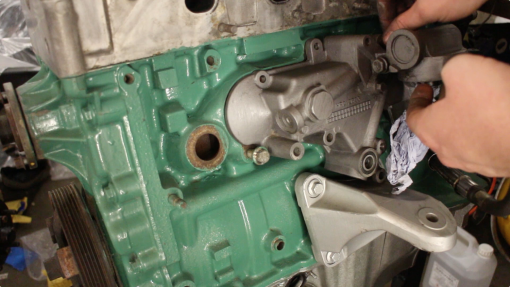

These seatbelt mount brackets panels came from YRM Metal Solutions. They've been laser cut, CNC folded and galvanised. The result is excellent tolerances and a lasting repair!

Fitting is easy, the old seat belt mount bracket is removed.

And any flaky aluminium corrosion is stripped away with a wire wheel.

We applied Dinitrol cavity wax to the tub, before offering up the repair section.

It's supplied in 2 pieces (otherwise it wouldn't fit), there are a few holes that have captive nuts so bolts were installed to hold the panel in place, along with a G clamp.

Before drilling the holes for each fixing.

There are a total of 48 M8 bolts required. Once secured, these panels are very strong! There's zero movement and the whole lot will be overcoated with stone chip for further protection.

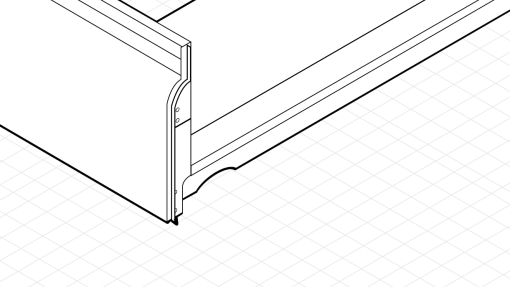

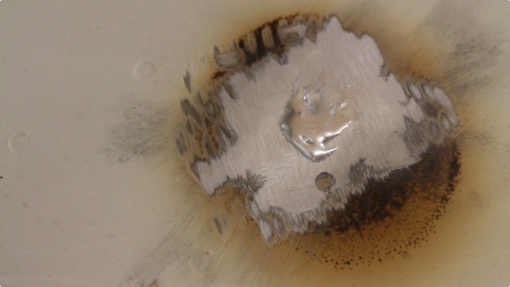

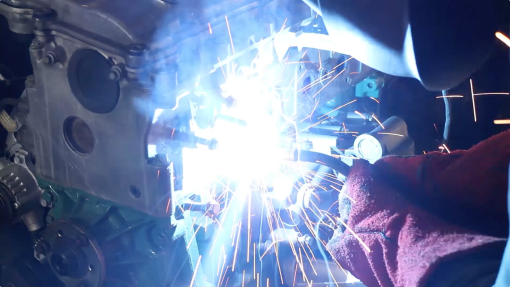

Moving onto the strike plate, this often corrodes where the tub fits to the sill rail, due to bimetallic reaction. The aluminium turns to a powder and is completely unusable.

So to repair we'll fit new strike plate sections from YRM too. These are pretty simple to fit, and once prepared and painted, it should be as good as new.

We're starting by marking off where we'd like to cut off the strike plate.

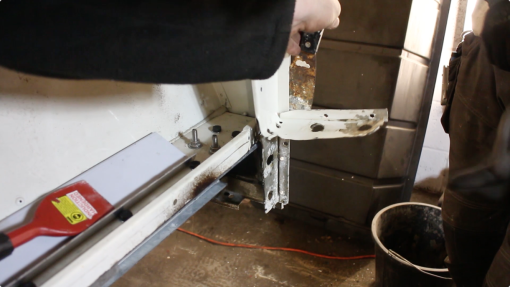

And using a spot weld drill to remove the spot welds and rivets below the line, including on the seal retainer.

Then, using a bolster chisel and a scraper, we can begin to prise the 2 skins apart

Finally, we scored a mark with a Dremel multi tool along the line. Then we were able to fracture the corroded part off, with a clean break formed along our score.

had nothing to do with opie oils but i dont find them very competitive, as i can get oil and filter from a dealer, cheaper than they can supply oil for,

had nothing to do with opie oils but i dont find them very competitive, as i can get oil and filter from a dealer, cheaper than they can supply oil for,