You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your bench vice(s)

- Thread starter MattF

- Start date

james butler

Member

- Messages

- 1,522

- Location

- birmingham england

i will have to borrow one but how do i get the two main halves of the vice apart? would be handy to be able to take it apart to get to the screws properly.Impact driver?

ive never took one apart before and this one has a quick release mech.

Arc Tourist

Member

- Messages

- 4,930

- Location

- Wales

Hi James,

Other than drilling them out, I would try heating up the screw heads with a pencil torch to expand and break the bond. Once cooled, they might be easier to remove.

Other than drilling them out, I would try heating up the screw heads with a pencil torch to expand and break the bond. Once cooled, they might be easier to remove.

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

i will have to borrow one but how do i get the two main halves of the vice apart? would be handy to be able to take it apart to get to the screws properly.

ive never took one apart before and this one has a quick release mech.

On that vice there is a taper pin at the back which you have to knock out of a mandrel. After that just wind her out. Bear in mind having another vice makes the process much easier when getting the screws out as impact drivers work best on stationary objects.

Arc Tourist

Member

- Messages

- 4,930

- Location

- Wales

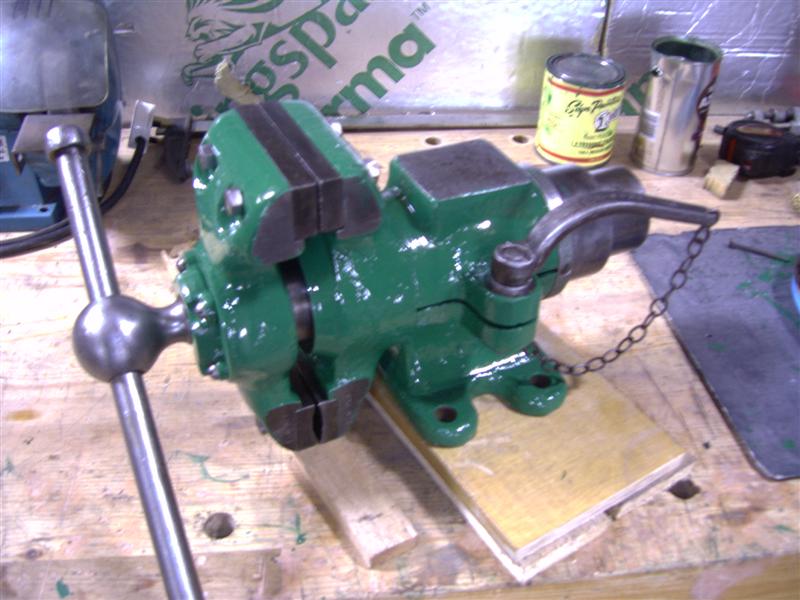

Meh. Looks good to me. Points for not painting the anvil face like some people do.

More I think about it, I shouldn't have painted the horseshoe handle retainer; but then its easy enough to strip it. I am kind of meticulous regarding things being done right and looking right.

Green is good, right ?

james butler

Member

- Messages

- 1,522

- Location

- birmingham england

thats the problem ive got as this is the only vice ive got as i gave away the other one, hence why ive left it with battered jawsOn that vice there is a taper pin at the back which you have to knock out of a mandrel. After that just wind her out. Bear in mind having another vice makes the process much easier when getting the screws out as impact drivers work best on stationary objects.

dobbslc

Forum Supporter

- Messages

- 12,411

- Location

- Hertfordshire UK

thats the problem ive got as this is the only vice ive got as i gave away the other one, hence why ive left it with battered jaws

You know what you have to do then......

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

You know what you have to do then......

Get to your phone book and look up the area code for Barnsley...

slim_boy_fat

Member

- Messages

- 29,540

- Location

- Scottish Highlands

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

This is the problem. You need a vice to repair the other vice...and then you need a few more just because. It's the same with lathes. You need a lathe to repair the other lathe that you got for repairing the other lathe.

slim_boy_fat

Member

- Messages

- 29,540

- Location

- Scottish Highlands

This is the problem. You need a vice to repair the other vice...and then you need a few more just because. It's the same with lathes. You need a lathe to repair the other lathe that you got for repairing the other lathe.

Well, you're the forum expert in that.....

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

This is true I agree. Can't help it....I still hunting for a monster vice for my drillWell, you're the forum expert in that.....

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

This is true I agree. Can't help it....I still hunting for a monster vice for my drill

An Abwood would be nice (and was what I wanted for my Fobco) but then the record turned up. Lots of options, just takes a lot of hunting time. An interesting machine vice I once saw was a Woden drill vice made of phosphor bronze, for use in the manufacturing of munitions where sparks could prove devastating.

Viceman

Member

- Messages

- 83

- Location

- West Midlands, England

Looks like a Record 34, just undo and remove the bolt holding the horseshoe plate on. Press the quick release lever tight against the turnscrew and pull both the turnscrew and quick release out. Simples. Now, Remove the spring, washers and tube spacer now loose from the underside of the vice. Then pull the slider out from the main body. IF it is a No 34 it will have slow taper screws which are a right s*d to get out and has already been covered by others on how to remove, and again IF it is a No34 you might consider replacing with jaws from a No 4 which have the same fixing centres and same width but normal countersunk heads that are a lot easier to remove next time. Just need the fine thread countersunks to match the threads in the vice.i will have to borrow one but how do i get the two main halves of the vice apart? would be handy to be able to take it apart to get to the screws properly.

ive never took one apart before and this one has a quick release mech.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Am planning a visit to the pumphouse. Looks a very interesting placePurely by chance I've been sorting through photos on my phone and came across this

View attachment 147049

It's at a local museum that houses a couple of horizontal pumping engines and various bits of elderly transport - http://e17pumphouse.org.uk/

I keep meaning to volunteer when I can find the time.

This is true I agree. Can't help it....I still hunting for a monster vice for my drill

The drill table is big enough that you could use a small bench vice as a temporary measure, something like a record no 3. Add a piece of wood or box steel as a spacer on top of the slide & you've got a drill vice.

zeppelin builder

Member

- Messages

- 2,166

- Location

- peoples republic of scotland

how do you get the screws out of the jaws if theyre in tight?

i would love to rebuild my vice but cant even get the jaws outthe flat head screws are well stuck.

tig a bit of flat bar on em

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

tig a bit of flat bar on em

Note I sheared one on my 34P and then the jaws were never the same again, the rear one was always loose (which ended in me selling it, complete with snapped easyout in there too). In hindsight I’d have left them in there and just attacked it with a wire wheel - the jaws are hardened steel and very difficult to mark unless you’re actually cutting into them.

Arc Tourist

Member

- Messages

- 4,930

- Location

- Wales

Paint dried, kinda shiny but doesn't look too bad. I think this one is a keeper.

.

.