Screwdriver

Member

- Messages

- 10,912

Good thinking - and investment casting can get very close (see high pressure section turbine blades in jet engines - main surfaces not machined) but that's not cheap.

A normal foundry won't do investment. A precision foundry will, but pricy. An art foundry will, but prob not the high precision needed.

And then your 3D printing material can't be any old plastic - must be a fully melt-out-able wax type -- no good if crud left in the mould on burn-out.

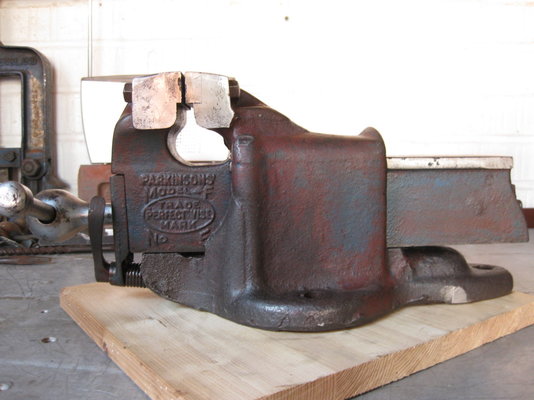

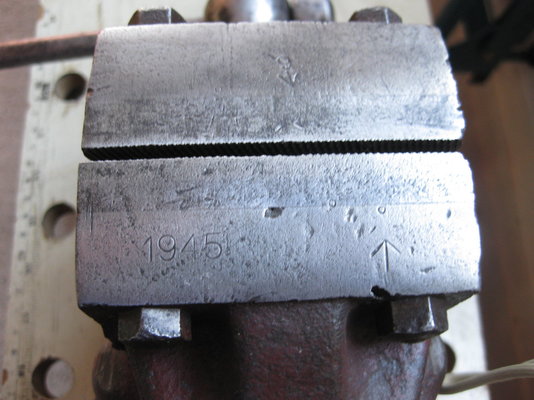

And then I'd say it still won't be precision enough for this type --- redesign the vice?

Ah well - maybe some other project?

Moldlay wax filament specifically designed for lost wax casting.