You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your bench vice(s)

- Thread starter MattF

- Start date

dannysheff

Member

- Messages

- 636

- Location

- UK Sheffield

acquired my second "75", amazing condition, must of been garaged its whole life

I didn't know record highlighted the lettering in black. Also note the anvil removes to the right side only.

View attachment 430992

View attachment 430993

View attachment 430994

View attachment 430995

and the rotator at the back?

Dieselman 63

Forklift Certified

- Messages

- 5,682

- Location

- Wellington, New Zealand

Try putting a 6” board in with no room to hold behind, what a nightmare. Jaws are best proud from the bench.View attachment 426947

This may make it clearer. Having the static jaw flush to the skirt allows you to clamp longer pieces to the bench itself so they don't whip around when planning.

SteveB58

Member

- Messages

- 505

- Location

- Essex, England

I'm no chippy, my experience has been gained from t'net, and books. However, if the jaws are proud you can't use a shooting board or, by using dogs, work on jobs that are wider than you can fin in your vice.Try putting a 6” board in with no room to hold behind, what a nightmare. Jaws are best proud from the bench.

dannysheff

Member

- Messages

- 636

- Location

- UK Sheffield

yup -- looks like that conical swivel, which is good and much more scarce than the vice itself.Parkinson Handy. Good vice. Swivel base is a nice inclusion.

rosinante

Member

- Messages

- 1,342

- Location

- Cornwall England

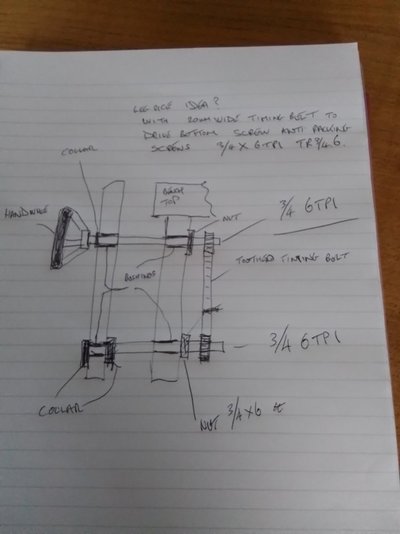

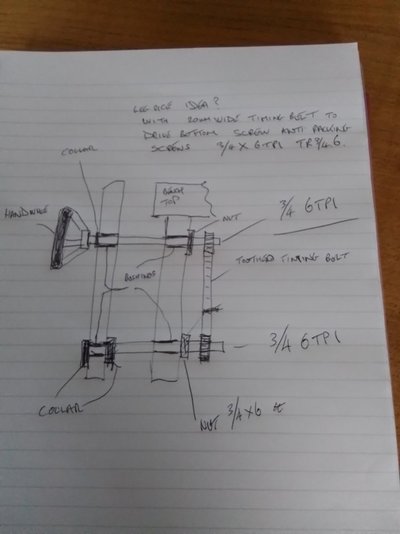

Hi people with many vices, would the idea in the sketch work? Woodworking leg vice with two screws linked by a toothed timing type belt to prevent or minimise racking to an acceptable level for use , have seen lots of other ideas but fancy a go at this just to be different, I have the screws and nuts albeit left hand thread, soon get used to that , I hope , excuse the mixed units of measurements , I'm old ,

Any constructive criticism welcome,

Cheers

Any constructive criticism welcome,

Cheers

cheb

Member

- Messages

- 3,585

- Location

- Outer Hebrides

yup -- looks like that conical swivel, which is good and much more scarce than the vice itself.

It is a conical swivel, it's also looked to be in good condition when I had a peek at it.

I'll take more photos later.

Arc Tourist

Member

- Messages

- 4,935

- Location

- Wales

stanley 700 cast iron corner vice

View attachment 428106

Ahhh, your post reminded me; I have one of these which my Dad kept with his door installation bench. It also has the fibre jaws. Don't recall if I've posted a picture if it before ?

Ahhh, your post reminded me; I have one of these which my Dad kept with his door installation bench. It also has the fibre jaws. Don't recall if I've posted a picture if it before ?

SteveB58

Member

- Messages

- 505

- Location

- Essex, England

Not sure what the advantage of the second driven spindle. I'm assuming that it is a type of leg vice which often have the bottom pivot pegged to allow the clamping of a variety of shapes and sizes. Further is there a risk of your chain becoming clogged with shavings or sawdust? An interesting idea, and is love to see how you develop it.Hi people with many vices, would the idea in the sketch work? Woodworking leg vice with two screws linked by a toothed timing type belt to prevent or minimise racking to an acceptable level for use , have seen lots of other ideas but fancy a go at this just to be different, I have the screws and nuts albeit left hand thread, soon get used to that , I hope , excuse the mixed units of measurements , I'm old ,

Any constructive criticism welcome,

Cheers

View attachment 431769

rosinante

Member

- Messages

- 1,342

- Location

- Cornwall England

The bottom screw is to minimise racking, usually and traditionally they have a bar and a peg , a Saint something cross, latest a linear guide has been used, in my mind the second screw hopefully will eliminate that , also will give me the impetus to start another unnecessary project, consisting of this vice and apart from the vice which will be cherrywood 30mm mdf triple laminated for legs, stretchers and top,Not sure what the advantage of the second driven spindle. I'm assuming that it is a type of leg vice which often have the bottom pivot pegged to allow the clamping of a variety of shapes and sizes. Further is there a risk of your chain becoming clogged with shavings or sawdust? An interesting idea, and is love to see how you develop it.

Cheers

dannysheff

Member

- Messages

- 636

- Location

- UK Sheffield

I expect you may have seen this type, Rosi. - commercially made (Yorkshire?) - interesting to me is that various versions I have seen of this type all have the big bolt thro' the static jaw as if it should be mounted on the corner of a bench and removable.

oak body, brass nut steel screw nd faces

oak body, brass nut steel screw nd faces

dannysheff

Member

- Messages

- 636

- Location

- UK Sheffield

and if anyone knows about the slot in the steel jaw faces, I'd be interested - seen this feature in various examples.

rosinante

Member

- Messages

- 1,342

- Location

- Cornwall England

Yes , similar but my idea is just a variation , essentially eliminating the bottom anti rack drviceand if anyone knows about the slot in the steel jaw faces, I'd be interested - seen this feature in various examples.

Identical to my high school 4th form projectDug this out the shed. Belonged to my grandfather, so it’s a good few years old. No makers names on it. It’s not very big , need a bigger one

View attachment 224424

View attachment 224425

Migmac

Forum Supporter

- Messages

- 8,380

- Location

- Kintyre. Scotland

Pretty close ! My Grandfather was born early 1900’s. Would they have gotten to make things like that in school back then ?Identical to my high school 4th form project

View attachment 431923

good question not sure if they had the resources for kids to make stuff like that at school, could be an apprenticeship piece though, funny how the pattern hasnt changed much, i made mine around 1984ishPretty close ! My Grandfather was born early 1900’s. Would they have gotten to make things like that in school back then ?