You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

dan.taylor.1

General Tinkererer

- Messages

- 2,768

- Location

- Kendal, Cumbria

I've a pair of KEF C10 I'd part with. They're black though.Made a 'hi-fi' shelf. I used shellac which I wiped on. I was going to go for a dark finish similar to the bookshelf. I am still experimenting with dark finishes on pine. I used ruby dewaxed shellac for this, but it turned out pretty darn light when I appled it with a rag. The antenna arrangement is temporary.

I also nee d proper speakers, and likely a pair of shelves for them.

Munkul

Jack of some trades, Master of none

- Messages

- 7,661

- Location

- Cumbria

You must be quiet atm, how many sets of pegs have you made now? This the 3rd?Decided to make a start on the one piece pegs today.

Hood

I am obsessed.

- Messages

- 17,478

- Location

- Carnoustie, Scotland

Nah, loads on just can't be ersedYou must be quiet atm, how many sets of pegs have you made now? This the 3rd?

Having said that I am currently having to do some real work

Regarding the pegs, once completed this will be the first full set, the previous set I only (sort of) finished one. It is currently on my Africa Twin, one side OEM the other custom

Thankfully you only see one side at a time.

Thankfully you only see one side at a time.Everyone will think you've dropped it!It is currently on my Africa Twin, one side OEM the other custom

Hood

I am obsessed.

- Messages

- 17,478

- Location

- Carnoustie, Scotland

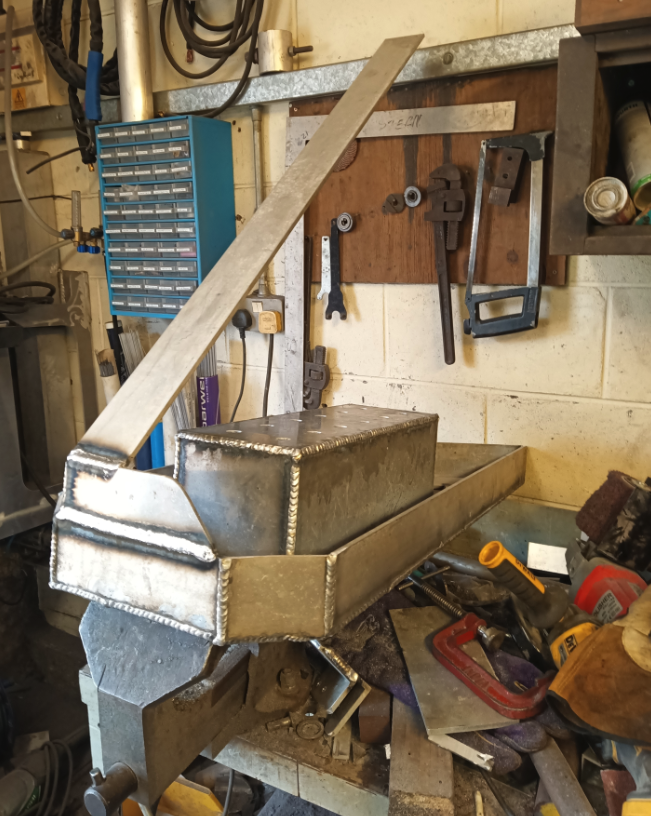

Finished just in time, bleeding screaming gale and the rain is starting.

Welded a leg on.

Made a couple of brackets and bolted them to the original table to hold the extension.

If he doesn't need the extension he just lifts it out of the brackets and stows it away some place.

Welded a leg on.

Made a couple of brackets and bolted them to the original table to hold the extension.

If he doesn't need the extension he just lifts it out of the brackets and stows it away some place.

Memmeddu

Member

- Messages

- 5,054

- Location

- Italia Sardegna

Disassembled 4 hydraulic cylinder ,two conventional and two with hallow rods .

Welded an hospital cart ,like bodywork welding .

Very satisfying.

Put a part material to make a burning guide to use both the cutting torch and plasma cutter.

Used on a side it will keep the plasma nozzle at 3mm from the plate , resting the retaining cap on the guide

On the other it will keep the cutting tip at 10mm from the plate , resting the tip nut on the guide .

Hopefully tomorrow I can start cutting and welding it together .

It will be roughly 600mm long.

Welded an hospital cart ,like bodywork welding .

Very satisfying.

Put a part material to make a burning guide to use both the cutting torch and plasma cutter.

Used on a side it will keep the plasma nozzle at 3mm from the plate , resting the retaining cap on the guide

On the other it will keep the cutting tip at 10mm from the plate , resting the tip nut on the guide .

Hopefully tomorrow I can start cutting and welding it together .

It will be roughly 600mm long.

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Hood

I am obsessed.

- Messages

- 17,478

- Location

- Carnoustie, Scotland

You jinxed meYou must be quiet atm, how many sets of pegs have you made now? This the 3rd?

Either that or I don't know my left from right, should have named them Port and Starboard and I would have been fine

Profile on the end of the lower one is wrong, it is the left hand pegs profile as the cut out section should be at the top

I set up the footpeg in the vice for the final cut which is the profile but I loaded the wrong bleeding code

So I will now have to order some more aluminium and make another right hand one, hopefully with a right hand profile on the end

Here is a vid of the operation before the cockup, cutting the ends with advanced clearing, 10mm DOC per pass. Shame I don't have a faster spindle as I could have ramped up the feedrate.

1min 18 seconds in is where it starts to cut the slot through the ends.

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

AndersK

Member

- Messages

- 1,490

- Location

- Sweden

Engineering is the art of being approximately right rather than totally wrong.Profile on the end of the lower one is wrong, it is the left hand pegs profile as the cut out section should be at the top

First piece often is a no go, second try is right at it. Then you make a third to achieve perfection

Right or wrong, they look great

selectedgrub

Member

- Messages

- 3,346

- Location

- New Zealand

Hood inspires me.

I reprinted them.

I reprinted them.

I thought it was get it nearly right, then be so busy it remains nearly right for the next decade, or until you stop making it . . .Engineering is the art of being approximately right rather than totally wrong.

First piece often is a no go, second try is right at it. Then you make a third to achieve perfection

Right or wrong, they look great

Nick DV

"That's the only name they ever gave me."

- Messages

- 1,673

- Location

- "A long time ago in a galaxy far, far away...."

Nice work, and always the smallest thing that causes the biggest delay!Should have been finished today but thabks to ironmongery directs website not adding the hinge plates to my basket I'm not

View attachment 331976 View attachment 331977 View attachment 331978

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

Finished welding the crud catcher for my T&C grinder. Not pretty but a but of paint should improve it no end

I used it as a way of improving my TIG welding. Thanks for all the help and support.

Quite pleased with the clamp for the shop vac.

Does need a Tee Nut making but that's a job for another day.

I used it as a way of improving my TIG welding. Thanks for all the help and support.

Quite pleased with the clamp for the shop vac.

Does need a Tee Nut making but that's a job for another day.

Hood

I am obsessed.

- Messages

- 17,478

- Location

- Carnoustie, Scotland

Well seeing as I now have a foot peg that is no use unless I want to turn into a bat and hang under the bike, I decided to have a wee mess with some engraving.

Ah, forgot, I killed my engraving tool a while back Ok so what about a 90 degree chamfer tool, nothing to lose as part is scrap anyway.

Ok so what about a 90 degree chamfer tool, nothing to lose as part is scrap anyway.

So drew it up, coded, set the peg up in the mill and pressed the button.

Quite happy with the result

Ah, forgot, I killed my engraving tool a while back

Ok so what about a 90 degree chamfer tool, nothing to lose as part is scrap anyway.

Ok so what about a 90 degree chamfer tool, nothing to lose as part is scrap anyway.So drew it up, coded, set the peg up in the mill and pressed the button.

Quite happy with the result

Brad93

Member

- Messages

- 18,728

- Location

- Essex, United Kingdom

Can you not just use a DBIT tool for the engravingWell seeing as I now have a foot peg that is no use unless I want to turn into a bat and hang under the bike, I decided to have a wee mess with some engraving.

Ah, forgot, I killed my engraving tool a while backOk so what about a 90 degree chamfer tool, nothing to lose as part is scrap anyway.

So drew it up, coded, set the peg up in the mill and pressed the button.

Quite happy with the result

View attachment 332115

![IMG_20220209_112839410_HDR[1].jpg IMG_20220209_112839410_HDR[1].jpg](https://www.mig-welding.co.uk/forum/data/attachments/328/328259-99bdd93b98ad27cbf30a7037b54b5a50.jpg)