You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

Just finished making this highly complex and sophisticated ground breaking circuit board.

It is so that I can enable/disable 3 clutches in the lathes gearbox when I only have 2 outputs spare on my PLC.

And yes I know I have PCB in the ladder description and it is not a PCB but I know what I mean

It is so that I can enable/disable 3 clutches in the lathes gearbox when I only have 2 outputs spare on my PLC.

And yes I know I have PCB in the ladder description and it is not a PCB but I know what I mean

slim_boy_fat

Member

- Messages

- 29,363

- Location

- Scottish Highlands

What does the croc look like after battling you?  At least that's one problem we don't have here, worst we might get is a big spider in the bath!

At least that's one problem we don't have here, worst we might get is a big spider in the bath!

At least that's one problem we don't have here, worst we might get is a big spider in the bath!

At least that's one problem we don't have here, worst we might get is a big spider in the bath! Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

When I thought about where the placement of the above board would be I realised that it would be better if the terminals were all facing me.

Searched for another scrap of vero board but could only find one bit big enough (I need to get some more ordered) so I set about soldering up a new one but I decided to go even more HiTech than before and added some LEDs.

Searched for another scrap of vero board but could only find one bit big enough (I need to get some more ordered) so I set about soldering up a new one but I decided to go even more HiTech than before and added some LEDs.

Jlg

Member

- Messages

- 2,586

- Location

- Cumbria

Was that the one you said about the crocodile in if so how were you being a jerkI asked Hitch to delete my last, it was poorly thought out,my apologist to all for being a jerk

slim_boy_fat

Member

- Messages

- 29,363

- Location

- Scottish Highlands

feeling sorry for myself

I'd say your were justified, after a close encounter of the snappy kind.

Pete.

Member

- Messages

- 15,057

- Location

- Kent, UK

And yes I know I have PCB in the ladder description and it is not a PCB but I know what I mean

Practice circuit board

Prototype circuit board

Jlg

Member

- Messages

- 2,586

- Location

- Cumbria

If you haven't drew blood your not doing it properly so all the picture shows was you did it properlystupid pic, feeling sorry for myself, i am tired of injuring myself, so much pain everywhere, gotta shape up

A friend of mine got quite involved with his men in sheds group, based in a large town in Bucks, they had a fair bit of kit, and a good number of members.

Being a very keen hobby woodworker and recently retired he joind to get out of the house from time to time.

After a while he ended up being responsible for keeping the gear in good condition, safe etc. He ended up spending all his time doing that and not enjoying his time there anymore so knocked it on the head totally.

Anyway, finished this off earlier;

Made the rose a couple of weeks ago, left it to go green a little bit. Turned the base earlier, from some yellow mahogany offcuts I have had for years. Bit of black spray, a burnish... and we have an aged looking base.

Glass dome from an old clock that went to the tip.

I was getting the same feeling from our MIS. I've been going there since June & I've yet to make any of the stuff other guys are making like furniture, etc. I've been mostly using my mechanical & electrical skills in repairing & restoring existing tools for others to use. The only woodwork I've done is to make a set of drawers for tool storage & shelve a storage room, again for tools.

My hard work has not gone unnoticed, I have just been given a set of keys for the mens shed.

Officially this is to open up the shed on the odd occasion that none of the other 3 keyholders can come in. Unofficially I can also come in & use the facilities for my own work.

Officially this is to open up the shed on the odd occasion that none of the other 3 keyholders can come in. Unofficially I can also come in & use the facilities for my own work.  This will be useful as I have nowhere at home dedicated for woodwork, if I need to do any I have to pull out the tools, set them up, do the work then put them away again. For a small job this is a pita, it takes longer to set up than doing the job!

This will be useful as I have nowhere at home dedicated for woodwork, if I need to do any I have to pull out the tools, set them up, do the work then put them away again. For a small job this is a pita, it takes longer to set up than doing the job!I am currently setting up a woodwork bench I have loaned to MIS but I have said it is my last job, I want to make something for myself next.

Dieselman 63

Forklift Certified

- Messages

- 5,868

- Location

- Wellington, New Zealand

I was getting the same feeling from our MIS. I've been going there since June & I've yet to make any of the stuff other guys are making like furniture, etc. I've been mostly using my mechanical & electrical skills in repairing & restoring existing tools for others to use. The only woodwork I've done is to make a set of drawers for tool storage & shelve a storage room, again for tools.

My hard work has not gone unnoticed, I have just been given a set of keys for the mens shed.Officially this is to open up the shed on the odd occasion that none of the other 3 keyholders can come in. Unofficially I can also come in & use the facilities for my own work.

This will be useful as I have nowhere at home dedicated for woodwork, if I need to do any I have to pull out the tools, set them up, do the work then put them away again. For a small job this is a pita, it takes longer to set up than doing the job!

I am currently setting up a woodwork bench I have loaned to MIS but I have said it is my last job, I want to make something for myself next.

I think it was you who told me to pillage the village when these sorts of chances come up and it's dead worthwhile. The amount of sandblasting I've done this year is ridiculous! My entire grinder bar the spindle and main 200kg casting have gone through the blaster which I no longer have access to at uni now that I'm finishing. Three wood vices, two machine vices, one 30kg bench vice, a plethora of parts for my new wood lathe, new knurling for the Fobco drill, a bench grinder completely refurbed, various bits for the Bantam and a few garden tools, it's been amazing. Even using the wood lathe at uni to demonstrate to my parents the sort of stuff I can produce was helpful and probably what meant I was allowed to buy it.

Dieselman 63

Forklift Certified

- Messages

- 5,868

- Location

- Wellington, New Zealand

Have you heard of a Coventry Climax air compressor mine had 6 pots to on the high stage and four on the low stage I ran a 10 mil Venturi nozzle sandblasting my steel boats I could blast of 4 foot by 12 foot plate one side in 12 minutes unfortunately the kids got into it and poured sand into the rocker box cover was a lovely old machine had a P6 Perkins which had a lot of talk not much horsepower it's had an over centre clutch I used to love it I ran a straight pipe and it had 2 axles 14 steering it was a fair bastard to back

This was a proper cabinet affair, gloves and a light and continuous feed.

slim_boy_fat

Member

- Messages

- 29,363

- Location

- Scottish Highlands

Today I was feeling a bit crabbit, so I thought I'd pinch an idea I saw elsewhere [might have been from @The_Yellow_Ardvark ?] and did this........

I'll probably/possibly give it a coat of paint to disguise the poor welding - it amazed me how long it took me to get 'back in the swing' after not welding anything for a while.

- it amazed me how long it took me to get 'back in the swing' after not welding anything for a while.

I'll probably/possibly give it a coat of paint to disguise the poor welding

- it amazed me how long it took me to get 'back in the swing' after not welding anything for a while.

- it amazed me how long it took me to get 'back in the swing' after not welding anything for a while.

Morrisman

Forum Supporter

- Messages

- 9,074

- Location

- Staffordshire, England

have you a step drill bit set?

I have one step drill, and a hole saw set. For the amount of drilling I do I really should invest in a better set of drills, step drills, countersinks etc.

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 20,094

- Location

- Going Away.

Today I was feeling a bit crabbit, so I thought I'd pinch an idea I saw elsewhere [might have been from @The_Yellow_Ardvark ?] and did this........

View attachment 157805

View attachment 157806

View attachment 157807

View attachment 157808

I'll probably/possibly give it a coat of paint to disguise the poor welding- it amazed me how long it took me to get 'back in the swing' after not welding anything for a while.

I have had crabs, but that's another story.

They are quick and easy to make and sell well at Boot sales.

But I am curious why today you made them?

But I am curious why today you made them?The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 20,094

- Location

- Going Away.

@Lazeyjack

Thank you.

It is only recently I have taken picture of what I make, this place is a help for that.

I like to see rubbish reborn. Not up cycled. But as something else.

DO NOT ASK ABOUT FENG SHAI!!!!!!!!!!!!!!!!!!!!

But Things like the crabs and horse shoe animal, friend's have put rules on the making.

So each one is different.

Thank you.

It is only recently I have taken picture of what I make, this place is a help for that.

I like to see rubbish reborn. Not up cycled. But as something else.

DO NOT ASK ABOUT FENG SHAI!!!!!!!!!!!!!!!!!!!!

But Things like the crabs and horse shoe animal, friend's have put rules on the making.

So each one is different.

Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

Started on a housing for a transducer early evening, will get it finished tomorrow hopefully. It is a 410mm long, 130mm wide by 83mm deep lump of Acetal and I love turning and milling this stuff.

This is what it will (hopefully) end up like.

This is what it will (hopefully) end up like.

Hood

I am obsessed.

- Messages

- 17,982

- Location

- Carnoustie, Scotland

The design was a kind of a too'ing and fro'ing between me, the owner of a previous Cat and Cheetah themselves, this seemed to be the best shape for high speed and it has proved much better than the conventional ones on other Cats.yes, normally, the fairing block would be sorta like a symmetrical wing, got keen there for a bit, thought, oh a boatie!!

This was the Cat the first one was fitted to, sadly don't have any pics of the transducer itself.

DennisCA

Member

- Messages

- 2,052

- Location

- Finland

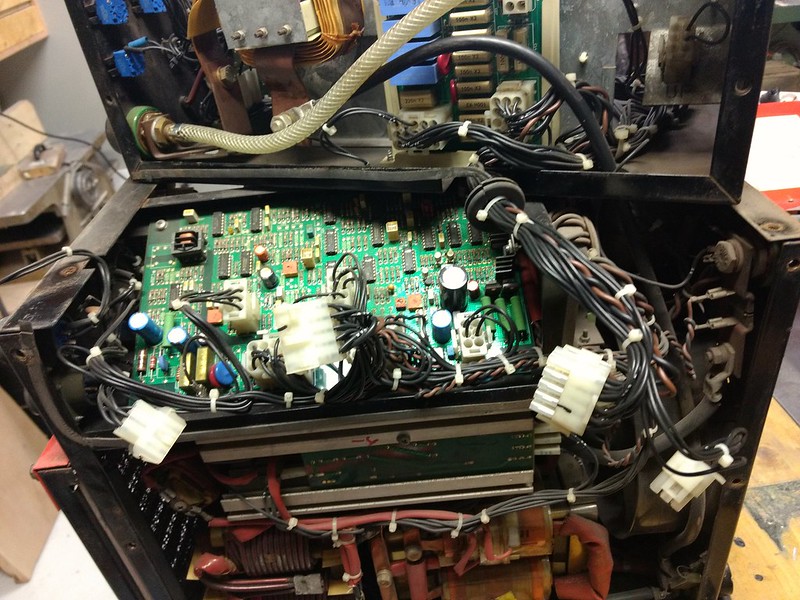

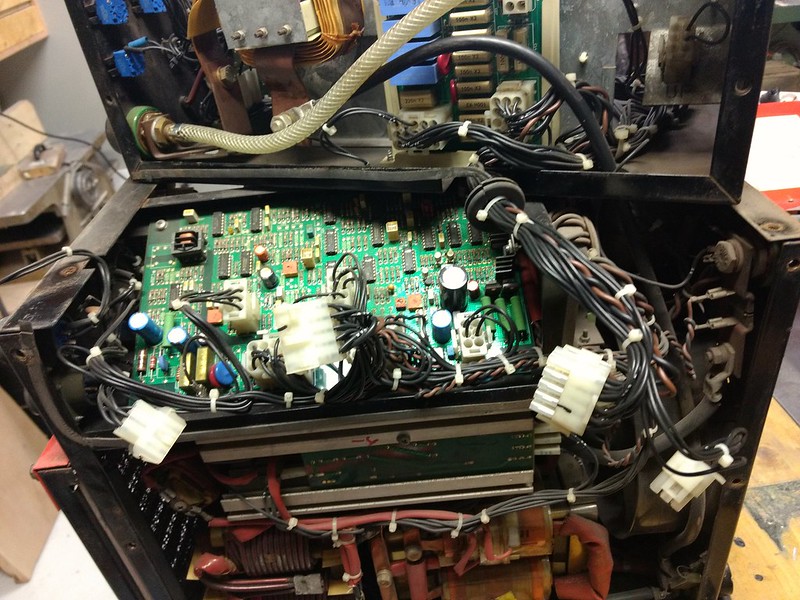

Made, no, more like repaired. Replaced all the Rifa capacitors in my welder, the old ones were degraded. I had to take the welder apart half way to get at the second board. But it was worth it, the arc now feels much nicer and more stable at low currents.

Jlg

Member

- Messages

- 2,586

- Location

- Cumbria

And all the trailers i have owned I have used a steel cable and used the hitch bolt to hold it one same as the trailers I have boughtI don't know what the regulations are like in your respective countries but in this countries there are hundreds of small trailer builders not to mention hundreds of thousands of home handyman equipped with a squirter craft welder and what they do is a weld a piece of chain on for the safety restraint

This is extremely bad engineering and I certainly wouldn't give any of them a warrant of fitness or mot as you say there in fact I would send them all back to where they came from another thing they do is they do not observe continuity of the chassis rails so they often step them stacked the rails on the apex really bad engineering how often do you see 100 ton low loaders with that sort of configuration this is how I normally do itView attachment 157910