You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Parm

Respect The Sound System

- Messages

- 17,901

- Location

- Towcester

I made this today (well yesterday but I fitted it today). Just a bit of 12mm thick flat bar with a bit of pipe welded on the end and a bolt hole in the other, a rubber bung down the pipe to hold the jet tube to dampen vibrations and hooked it up to a diesel jetwash bowser.

View attachment 103495

It's for keeping the dust to a minimum when breaking out concrete. Site were so impressed with it they gave me a voucher for a free breakfast

I like stuff like that!

Years ago I was involved in a decommissioning project at Hawell. The chaps on site made some special mounts to fix cheap n cheerful digital cameras to various points on the excavator so we could all see what was going on from the comfort of a cabin. Also there was an unknown chemical and radiation risk.

This was in days before go pro and stuff like that

Ton-up

Member

- Messages

- 2,236

- Location

- Essex, England.

Nothing worse than a heap of grinding. Grinding dust gets everywhere..ruins my old woman's Dyson...

And they dont like a rust stain in the shower either!

- Messages

- 13,447

- Location

- England

Not a fan of making angle frames with legs. Putting the legs on always seems more awkward than it should be. Not so bad if you can put the top sideways on the bench.

Thought I posted this last night, but forgot to press the post button

Made this up yesterday, Cookie cutter, this is the third one I've done now of varying shapes...nice simple one, virtually eliminates wastage of the dough.

Thought I posted this last night, but forgot to press the post button

Made this up yesterday, Cookie cutter, this is the third one I've done now of varying shapes...nice simple one, virtually eliminates wastage of the dough.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Template making today.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

LOL. Yes have got loads of different size of sheet steel as I wentered shopping this week. And got every other size via the one I want. Wanted 1.5mm. Got 1mm.2.5mm.3mm ect.I don't think it'll last long made out of paper mate. It needs to be fabricated out of something like sheet steel

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

No expense spared here ..state of the art equipment lol ....I see you're using the CAD design system for the templates.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Guys I need a bit of help here...the template I am making is 1.5mm steel..now on the drivers side I will be using a floor mounted pedal box. I have seen them mounted on a box that's welded to the floor pan. I would like to incorporate a box with the panel I will be making. But not sure if 1.5 mm is adequate for a pedal box.

arther dailey

Member

- Messages

- 6,559

- Location

- England

Can understand your thinking, my iveco daily when bleeding brakes you can see servo move, its solid no rust, but not un common for bulkheads to crack. Is there room for some cross bracing where box mounts? engine bay side? how do you stand with safety regs on something like this?

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Have just spoke to a motor sports company and they use 2mm or 2.5mm . But always good to here other opinions.Can understand your thinking, my iveco daily when bleeding brakes you can see servo move, its solid no rust, but not un common for bulkheads to crack. Is there room for some cross bracing where box mounts? engine bay side? how do you stand with safety regs on something like this?

- Messages

- 14,550

- Location

- UK

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

13 is seriously going some...View attachment 103608 Made 13 staircases today - welded and painted, loaded and gone. Regular job these, In batches of 60 odd, these are destined for London.

- Messages

- 14,550

- Location

- UK

Bit of a junk job, but a morning's work

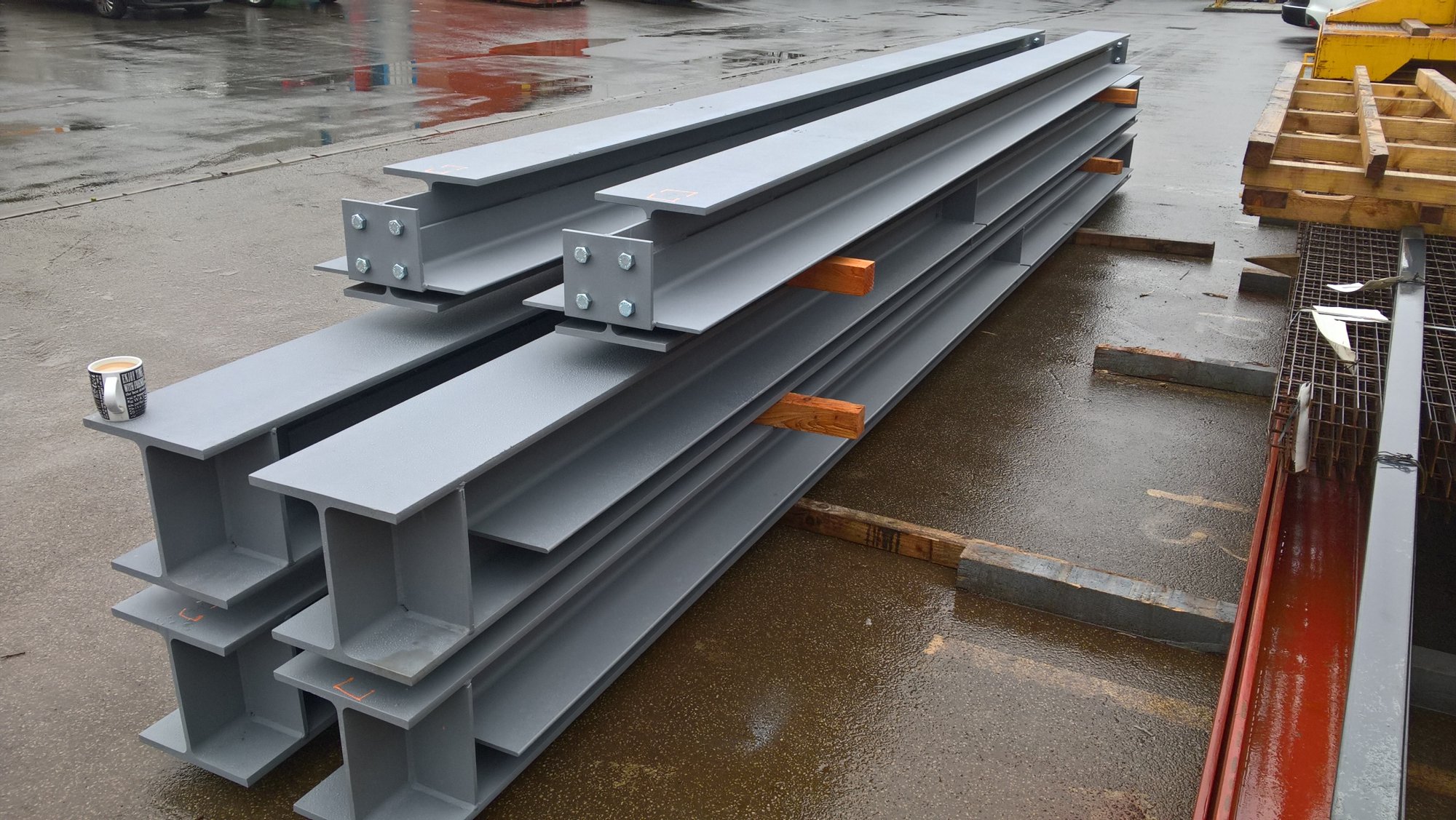

118kg per metre beams, remedial work in an existing building, one year old, where the floor is bouncing...7.5m long with 200*100 angles welded to either one or both sides. Just waiting for a wagon

118kg per metre beams, remedial work in an existing building, one year old, where the floor is bouncing...7.5m long with 200*100 angles welded to either one or both sides. Just waiting for a wagon

cumbriasteve

Moderator

- Messages

- 9,645

- Location

- Cumbria UK

I am surprised at the lack of safety, that full mug of tea could have easily tipped those beams, obviously no risk assessment done....

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

I would of least had three cups a tea on there...you don't mess about you guys...get in with the big stuffI am surprised at the lack of safety, that full mug of tea could have easily tipped those beams, obviously no risk assessment done....

Burdekin

Chief Bodger

- Messages

- 6,685

- Location

- Aberdeen

Guys I need a bit of help here...the template I am making is 1.5mm steel..now on the drivers side I will be using a floor mounted pedal box. I have seen them mounted on a box that's welded to the floor pan. I would like to incorporate a box with the panel I will be making. But not sure if 1.5 mm is adequate for a pedal box.

You're standard pedal box fixed into the firewall would be 1 or 1.2mm normally I would think but will have some extra stiffness with ribs etc in the pressing. But I don't really understand what you are doing, maybe a sketch or mock-up required.

As a general rule I use 2mm for structural like chassis rails or strengthening plates and for body panels whatever was the original size which for my old Volvos is normally 1 or 1.2mm. I'm going to box in from the chassis rail to the bulkhead where it curves upwards from the floor, extra strength but it's also a rust trap. I will make that from 2mm and will be fully welded.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Hi...my floor mounted pedal box will be very similar to the picture below....I have just finished making the bulkhead reinforcing plate that strengthens the footwell and the pick up points . I did make some inquiries and I was told plates reinforce are generally 2 mm 2.5 .You're standard pedal box fixed into the firewall would be 1 or 1.2mm normally I would think but will have some extra stiffness with ribs etc in the pressing. But I don't really understand what you are doing, maybe a sketch or mock-up required.

As a general rule I use 2mm for structural like chassis rails or strengthening plates and for body panels whatever was the original size which for my old Volvos is normally 1 or 1.2mm. I'm going to box in from the chassis rail to the bulkhead where it curves upwards from the floor, extra strength but it's also a rust trap. I will make that from 2mm and will be fully welded.