You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Thats better, Thanks.Best description (or comparison) of a diode is to think of it like a funnel: the water (or electrical current) is happy to flow through it one way but can't do so the other. Even the electrical symbol for a diode looks like a coffee filter holder

henry Kadzielski

Member

- Messages

- 1,218

- Location

- Australia Wollongong

The bottom machine, I have her twin sister, she is very happy here at my place

Woody.v8

Blue gluer

- Messages

- 4,181

- Location

- staffs

What's the dice?Was asked to do the hoovering done this instead View attachment 281389View attachment 281390

Very nice my friend.

Fraserb

Member

- Messages

- 1,562

- Location

- Scottish Borders

There may be a delay to mk2, I've forgotten an important ingredient for the Sunday roast.

There's been a bigger delay, had a rush job to finish.

Kram

Member

- Messages

- 7,465

- Location

- Sussex

If the battery polarity was wrong, that would have instantly exploded the diode, but Id expect it to take some time for the mosfet to fatigue from spikes.@Kram, so what do you reckon killed this Duratool multitool. It's 18V and the Makita battery is 18V. As I said the only thing I can think is the Ah on the Makita battery was too high.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,169

- Location

- Sevenoaks, UK

If the battery polarity was wrong, that would have instantly exploded the diode, but Id expect it to take some time for the mosfet to fatigue from spikes.

Right...I don't mind admitting my mistakes...

My finger is on the positive of the battery....spot the mistake?

Htf did I manage that? By getting the polarity marks the wrong way round on the 3D print!

Just the diode died d'you reckon?

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,188

- Location

- France, Brittany.

D'oh..Right...I don't mind admitting my mistakes...

My finger is on the positive of the battery....spot the mistake?

View attachment 281482

Htf did I manage that? By getting the polarity marks the wrong way round on the 3D print!

View attachment 281485

Just the diode died d'you reckon?

Kram

Member

- Messages

- 7,465

- Location

- Sussex

Ive done the same and worse!Right...I don't mind admitting my mistakes...

My finger is on the positive of the battery....spot the mistake?

View attachment 281482

Htf did I manage that? By getting the polarity marks the wrong way round on the 3D print!

View attachment 281485

Just the diode died d'you reckon?

Have you tried it correct polarity since? If the speed control still works, then just replace the diode

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,169

- Location

- Sevenoaks, UK

Ive done the same and worse!

Have you tried it correct polarity since? If the speed control still works, then just replace the diode

I'll give it a go tomorrow. Cheers.

Material?What's the dice?

Very nice my friend.

Dr.Al

Forum Supporter

- Messages

- 2,400

- Location

- Gloucestershire, UK

Right...I don't mind admitting my mistakes...

My finger is on the positive of the battery....spot the mistake?

View attachment 281482

Htf did I manage that? By getting the polarity marks the wrong way round on the 3D print!

View attachment 281485

Just the diode died d'you reckon?

If it's a simple DC motor speed controller, it probably has a circuit that looks a bit like this (the coil is the motor - image stolen from google image search as I was too lazy to draw it):

The MOSFET has what's known as an "intrinsic body diode", so should look more like this:

As a result of that, you have two diodes in series, both pointing "upwards" (from negative to positive). If you connect the power supply the wrong way round, you effectively short circuit the power supply through those two diodes and one or both devices will go pop (probably at that current an internal bond wire will break and it will have an unconnected pin).

If you're lucky, one or other will have broken and the break will have protected the other one (but it's pot luck which one will go first). If you're unlucky both will have broken. If you're really unlucky, other devices on the board will have gone as well (lots of ICs have parasitic or protection diodes that point "upwards").

slim_boy_fat

Member

- Messages

- 29,540

- Location

- Scottish Highlands

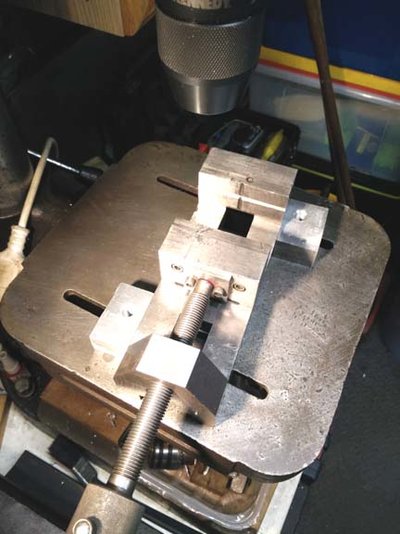

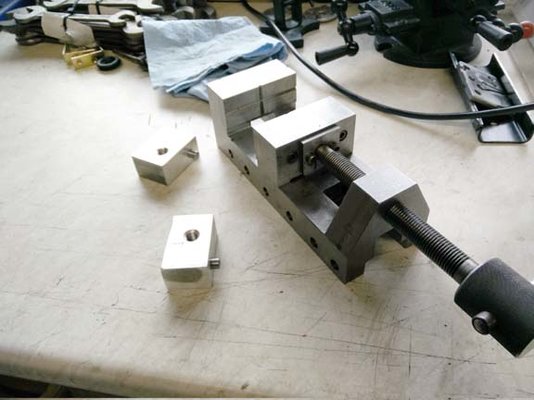

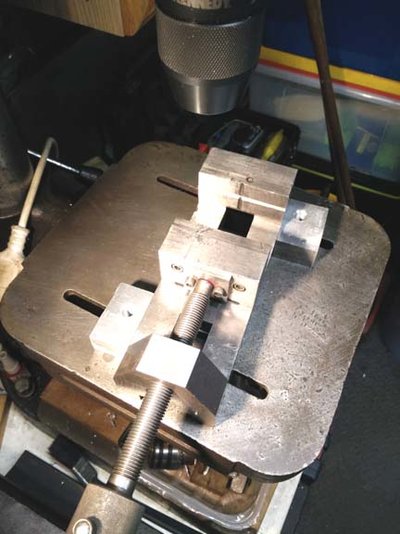

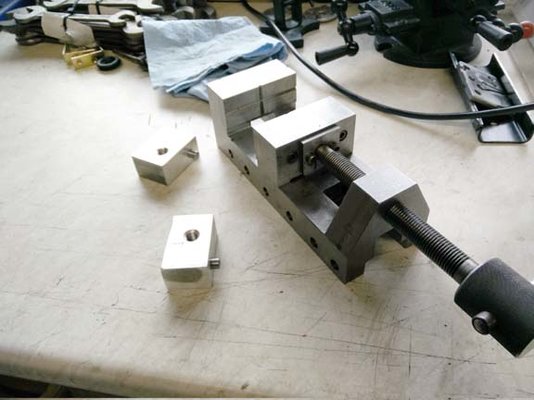

Today I made [well nearly finished] a pair of machine vice 'hold-downs for the pillar drill table [a big thanks to Mike @Wallace ] for the alloy blocks.

Thanks to the Member on here who suggested the pattern, sorry but I've forgotten who it was . They still need a tiny bit of fettling but I've proved they'll do the job - just have to get/make M10 bolts. Don't you hate it when a drill bit grabs and nearly breaks your wrist....

. They still need a tiny bit of fettling but I've proved they'll do the job - just have to get/make M10 bolts. Don't you hate it when a drill bit grabs and nearly breaks your wrist.... .

.

I want to radius the edges as they're sharp but don't have a suitably profiled milling cutter. I'm thinking I might carefully & gently try a router bit in the mill, but I'm not sure if they'll do alloy..... . Answers & the address of a good A & E, please.

. Answers & the address of a good A & E, please.

Thanks to the Member on here who suggested the pattern, sorry but I've forgotten who it was

. They still need a tiny bit of fettling but I've proved they'll do the job - just have to get/make M10 bolts. Don't you hate it when a drill bit grabs and nearly breaks your wrist....

. They still need a tiny bit of fettling but I've proved they'll do the job - just have to get/make M10 bolts. Don't you hate it when a drill bit grabs and nearly breaks your wrist.... .

.I want to radius the edges as they're sharp but don't have a suitably profiled milling cutter. I'm thinking I might carefully & gently try a router bit in the mill, but I'm not sure if they'll do alloy.....

. Answers & the address of a good A & E, please.

. Answers & the address of a good A & E, please.

Last edited:

Hood

I am obsessed.

- Messages

- 17,487

- Location

- Carnoustie, Scotland

Handrail hinges fitted today, will let someone else do the polishing

and pic of the aft section hinged open and in the keeper.

The two cap screws below at either side of the stanchion are adjusters to get the rails sitting level when shut, they will be replaced by grub screws but had forgotten to take them so just shoved capscrews in to check all was well.

and pic of the aft section hinged open and in the keeper.

The two cap screws below at either side of the stanchion are adjusters to get the rails sitting level when shut, they will be replaced by grub screws but had forgotten to take them so just shoved capscrews in to check all was well.

zx9

Forum Supporter

- Messages

- 5,182

- Location

- South East London

Router bits will probably 'do' aluminium for a while, lubricate with WD40 and don't complain that they no longer cut wood nicely afterwards.I want to radius the edges as they're sharp but don't have a suitably profiled milling cutter. I'm thinking I might carefully & gently try a router bit in the mill, but I'm not sure if they'll do alloy

Maker

Most folk just call me; Orange Joe

- Messages

- 10,555

- Location

- Keeler crater

I think I've seen Tom Lipton use a router bit in his mill on steel, aluminium wouldn't be a problem.Router bits will probably 'do' aluminium for a while, lubricate with WD40 and don't complain that they no longer cut wood nicely afterwards.

zx9

Forum Supporter

- Messages

- 5,182

- Location

- South East London

Rather him than me, I can trash end mills quick enough.I think I've seen Tom Lipton use a router bit in his mill on steel, aluminium wouldn't be a problem.

northwest

Searching for the Holy Grail.........

- Messages

- 6,008

- Location

- Manchester UK

Needed to make a couple of stools for the range as they have destroyed every type of bar stool we have had, some of em could break a cannon ball! Anyhow these are fast and dirty, fit where they touch tripod style stools. So while I was at it, going like a lunatic I decided to make a stand for my little folder. Naturally I should have thought it through a bit more but you only get to know this towards the end

Chopped a few bits up:

Mostly 30mm 3mm wall box but 40mm for the stand:

They came out well, made three stools:

Naturally, back at base I realised the error, cant get bolts through:

Ahhhh.... But I have a tig welder and some stainless bushes in 10mm:

Powder coat tomorrow.

Chopped a few bits up:

Mostly 30mm 3mm wall box but 40mm for the stand:

They came out well, made three stools:

Naturally, back at base I realised the error, cant get bolts through:

Ahhhh.... But I have a tig welder and some stainless bushes in 10mm:

Powder coat tomorrow.