slim_boy_fat

Member

- Messages

- 29,540

- Location

- Scottish Highlands

Nice little picket gate

Very neat!!

[that'll keep the dachshunds in...

[that'll keep the dachshunds in...

]

]Nice little picket gate

[that'll keep the dachshunds in...

[that'll keep the dachshunds in...

]

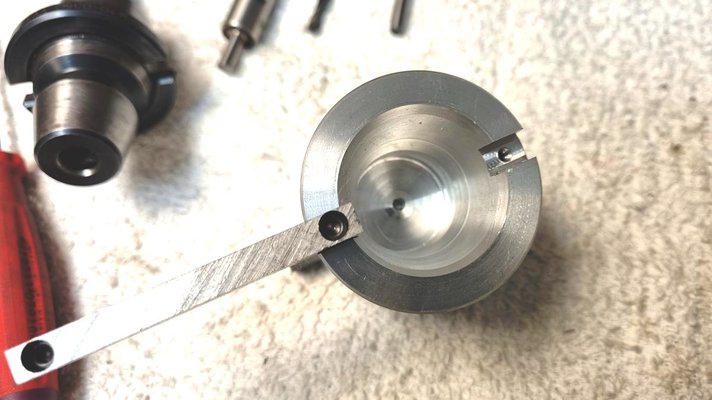

]hope it doesn't get too hot or you'll need to wear oven gloves. but its looking goodMade a knob

View attachment 282176

It's a handle for a cast iron casserole pan, the original was some brittle plastic and broke months ago. I did the bottom with a form tool ground from a parting blade on it's side, couldn't be bothered to grind a concave tool for the top so that was just freehand with a big corner radius tool and a file.M6 thread in the bottom to hold it to the lid and to conveniently hold it for turning the top face, it probably wouldn't have held up to the cutting force on an inch long form tool anyway.

Needs a bell end on it.Didn't have a proper spanner for the ER40 so a quick drawing in Fusion.

View attachment 282162

Some 5mm stainless onto the plasma.

View attachment 282165

I now have an ER40 spanner and it won't rust

View attachment 282166

I wondered who it was in my workshop earlier, are you on holiday? Shouldn't really be travelling to foreign climes at this time you know.It's got one.

so will have to wait 20 hours and more sanding. I swapped the 1.9mm tip, much better no new runs. The fan size about double but I dont understand it. Just checked a review and the guy was getting 17cm with a 1.2tip

so will have to wait 20 hours and more sanding. I swapped the 1.9mm tip, much better no new runs. The fan size about double but I dont understand it. Just checked a review and the guy was getting 17cm with a 1.2tip

Finished. Painted with Lidl metal care and faced with orange leather. Just waiting for the contact adhesive to dry.A guitar stand. Only about the 4th thing I've fabbed. Don't look too closely at the welds: they will get better with practice and it's all well stuck. Clamping things at odd angles was a challenge and it's not exactly precision work but it does what it is supposed to.

View attachment 282105

Hey, another kiwi. Gidday.^^ Nice simple practical design.

Good work thanks for sharing.

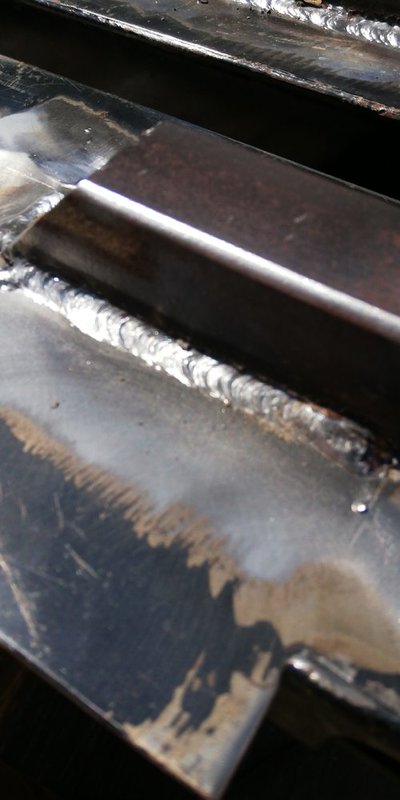

They won't fall off that's for sure.After maybe a month or two I've welded something.

Truck sides column , just added two Square tube receivers for a stiffening bar ,to avoid them to spread open .

I'll weld them on the truck bed most likely next Friday .

Considering that it's been awhile since I've welded something , that it's a fillet joint on 2mm box tube and 10mm plate , that I've used 2.5mm(3/32") 7018 for that .

I think that's not too bad I believe.

It will be way easier to weld them in place ,10 on 5mm vertical up

View attachment 282327 View attachment 282328 View attachment 282329 View attachment 282330 View attachment 282331

Lumpy red poo.

View attachment 282413

Is that for presetting the tool heights or just for tightening?Well, it's different. Need to see it all back together, will prolly look good.

Myself, I made a toolholder for the new quickchange system, fast n dirty. It too came out okay, I was using the system itself to do the drilling and machining and it is one of the best things I have bought. Need more toolholders but they are going to have to wait a while just now. I have milled a 10mm recess in the base and bolted a bit of keysteel in there so when I am using it I just grip it in the vice and off I go.

View attachment 282414View attachment 282415View attachment 282416View attachment 282417View attachment 282418