Dev

8th generation, Weyland type

- Messages

- 1,307

https://www.mbfg.co.uk/isopropyl-alcohol-ipa.html as well

RS do it as well. For twice the price of course.

RS do it as well. For twice the price of course.

I buy mine from Farnell in aerosol:Regards cleaning the print sheets, where do you guys get the IPA from? Do any highstreet type shops sell it?

Probably better, but IPA is quickHot soapy water and dried with kitchen Roll is just as good as IPA to be honest.

Well the printer is together and I hope I have calibrated it correctly. I printed the batman logo first to check the first layer adhesion, which seemed to work, and then the tree frog, which again came out reasonable.

I to learn the slicing software now and also learn the ins and outs making good usable prints. I also need to get some PETG on order as I currently only have silver and orange PLA.

Regards cleaning the print sheets, where do you guys get the IPA from? Do any highstreet type shops sell it?

By the way, I had one of the small screwdriver sets already. It actually came from B&M bargains and was about £5 when I got it. I think they still stock them but a pound or two more. It doesn't include the extension but it worked a treat putting the printer together. I also had a set of the cheap jewelers screwdrivers. They were useful for scraping out the slots and recesses for screws and nuts so I will keep them handy for my own creations.

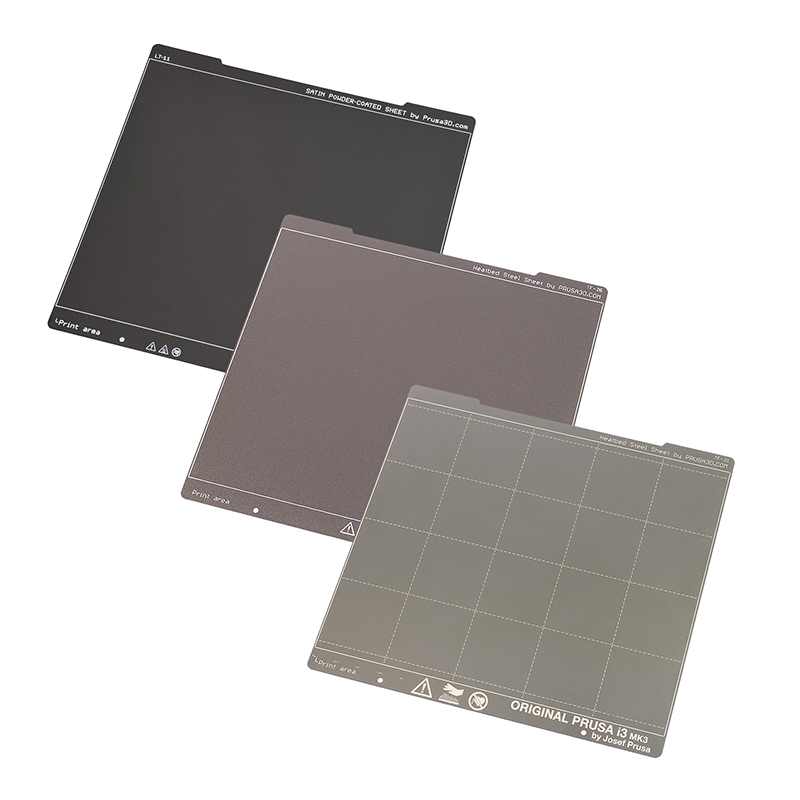

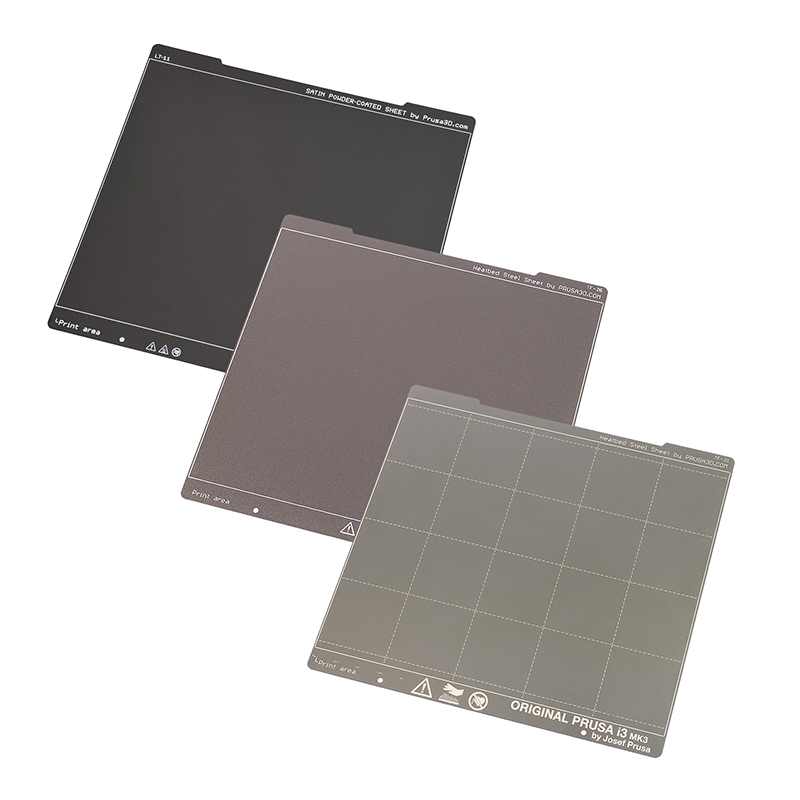

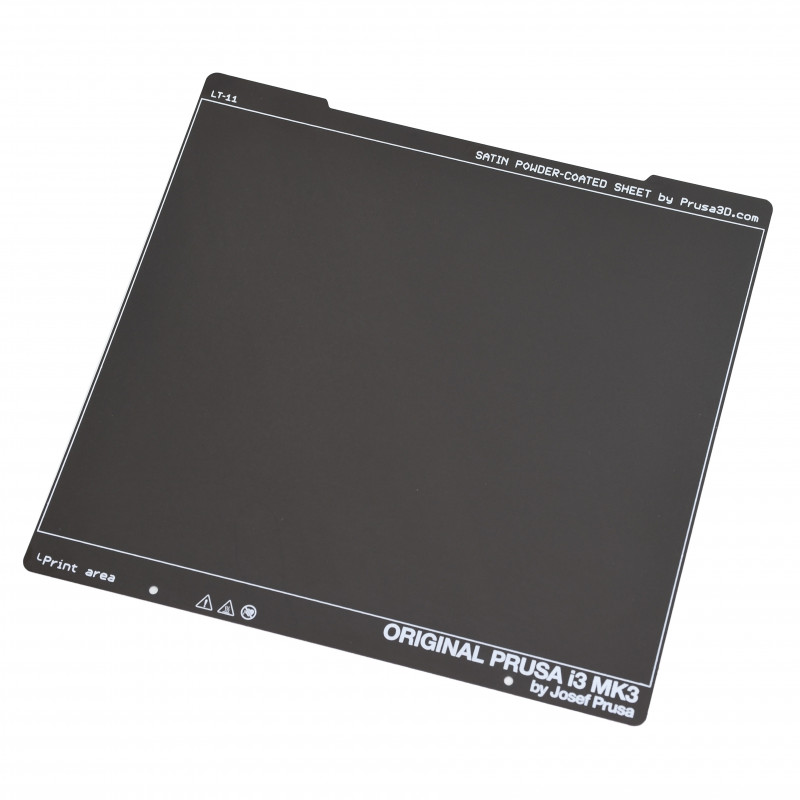

I bought the printer on a bit of a whim really as I don't have anything specific in mind for it, but something I have fancied for a few years. I bought it on prusas black Friday/cyber Monday deal so it included an extra roll of PLA, a textured sheet and free delivery.

So, now I need to find some things to make (not really ornaments or trinkets) to justify my purchase!

One thing I am thinking of is getting together some construction parts. I will start another thread on that so I can avoid hogging this thread, and on that note I will include an image of the tree frog to keep on topic!

Thanks again for the help folks.

View attachment 380393View attachment 380394

Note that for PLA & PETG, nothing should be added to the bed for adhesion with the prusa plates.If you use PVA/gluestick/hairspray for bed adhesion, water is the best solvent to clean up a removable bed. With a little bit of soap.

Once fully dry a quick wipe down with IPA will help keep it grease free before applying hairspray (in my case).

Note that for PLA & PETG, nothing should be added to the bed for adhesion with the prusa plates.

Top tip for stuck models...Cool. I don't have a Prusa so I refer to my Ender3 which has a glass plate (ceramic coat??) and the biggest problem I had initially was getting models off the plate as it sticks too well!

I destroyed a bed cover plate once when the plastic had become solidly welded to the surface.

On the contrary - for PETG you might want to add Something as a barrier and use the textured sheet as PETG adheres to the PEI coating on the bed REALLY tenaciously. Same goes for TPU - the flexible filament.Note that for PLA & PETG, nothing should be added to the bed for adhesion with the prusa plates.

Removing prints

To remove the printed object from the print surface, always wait until the steel sheet cools down to room temperature. Then you can take it off by bending the sheet inwards and outwards, but you may have to assist using a spatula to avoid damage to the sheet. For materials like PETG, ASA, ABS and PC Blend, and/or prints with a large first layer surface, a separation layer in the form of gluestick may be required.

Top tip for stuck models...

Put the model and glass plate in the freezer for a few hours.

On the contrary - for PETG you might want to add Something as a barrier and use the textured sheet as PETG adheres to the PEI coating on the bed REALLY tenaciously. Same goes for TPU - the flexible filament.

From the Prusa site:

Flexible steel sheets (guidepost) | Prusa Knowledge Base

The Original Prusa magnetic heatbed is designed to hold a…help.prusa3d.com

Ditto the satin sheetIt’s fine on the textured sheet which has the added benefit of a really nice surface finish.