- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Think I might have purchased an Atlas Lathe!!!

- Thread starter Exuptoy

- Start date

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,545

- Location

- The Shed of Danger, surrey, England

Zamak, it will weld like butter! Maybe screw and epoxy an ally plate over the crack?

Those magic ally rods (use with a propane torch and stainless brush/scraper) might weld Zamak/Mazak?

Dave H. (the other one)

Exuptoy

Member

- Messages

- 2,933

- Location

- Maesteg, South Wales

Those magic ally rods (use with a propane torch and stainless brush/scraper) might weld Zamak/Mazak?

Dave H. (the other one)

I have some.

Once I get the new one fitted I’ll straighten out the other and give it a shot.

Exuptoy

Member

- Messages

- 2,933

- Location

- Maesteg, South Wales

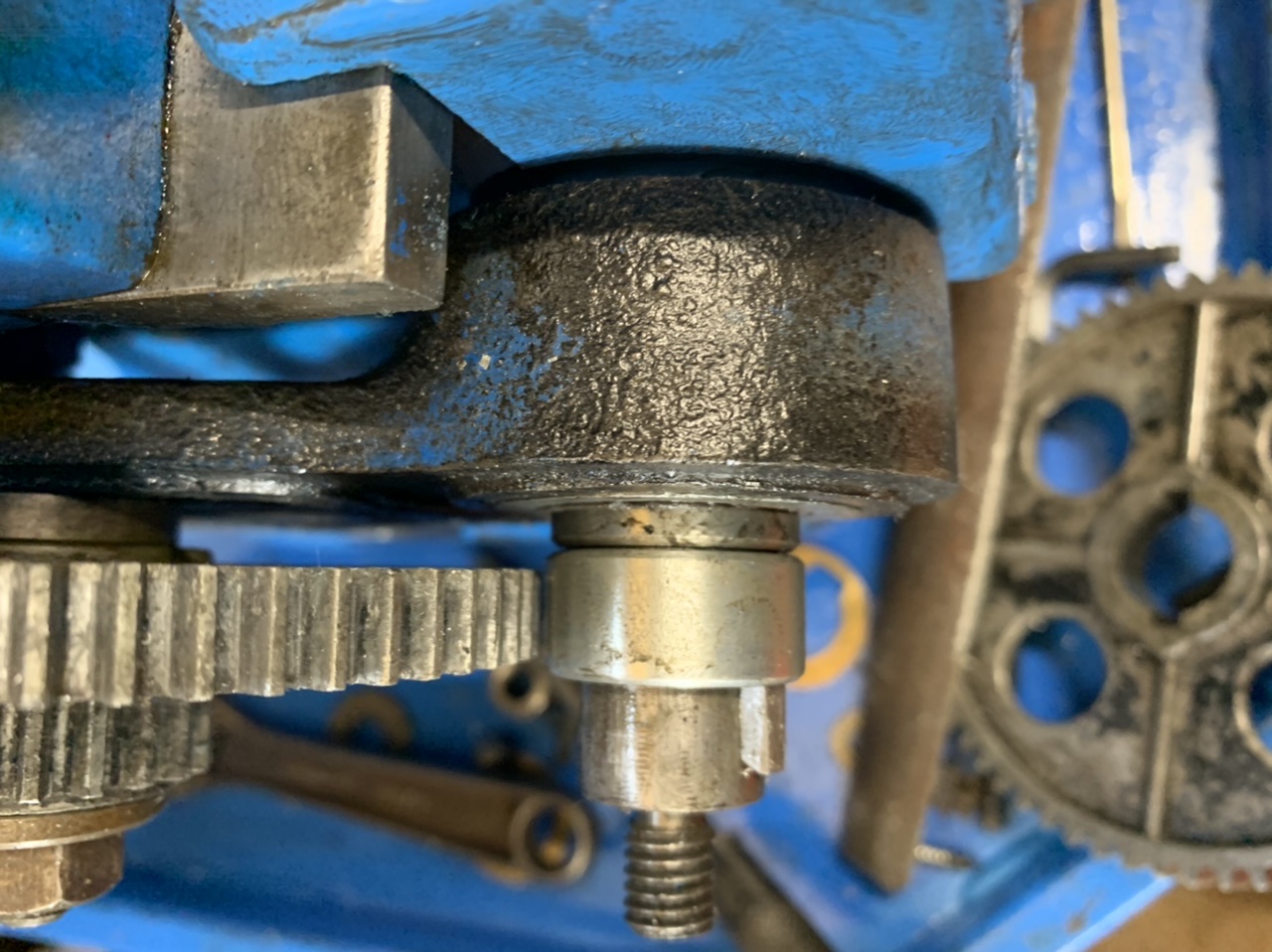

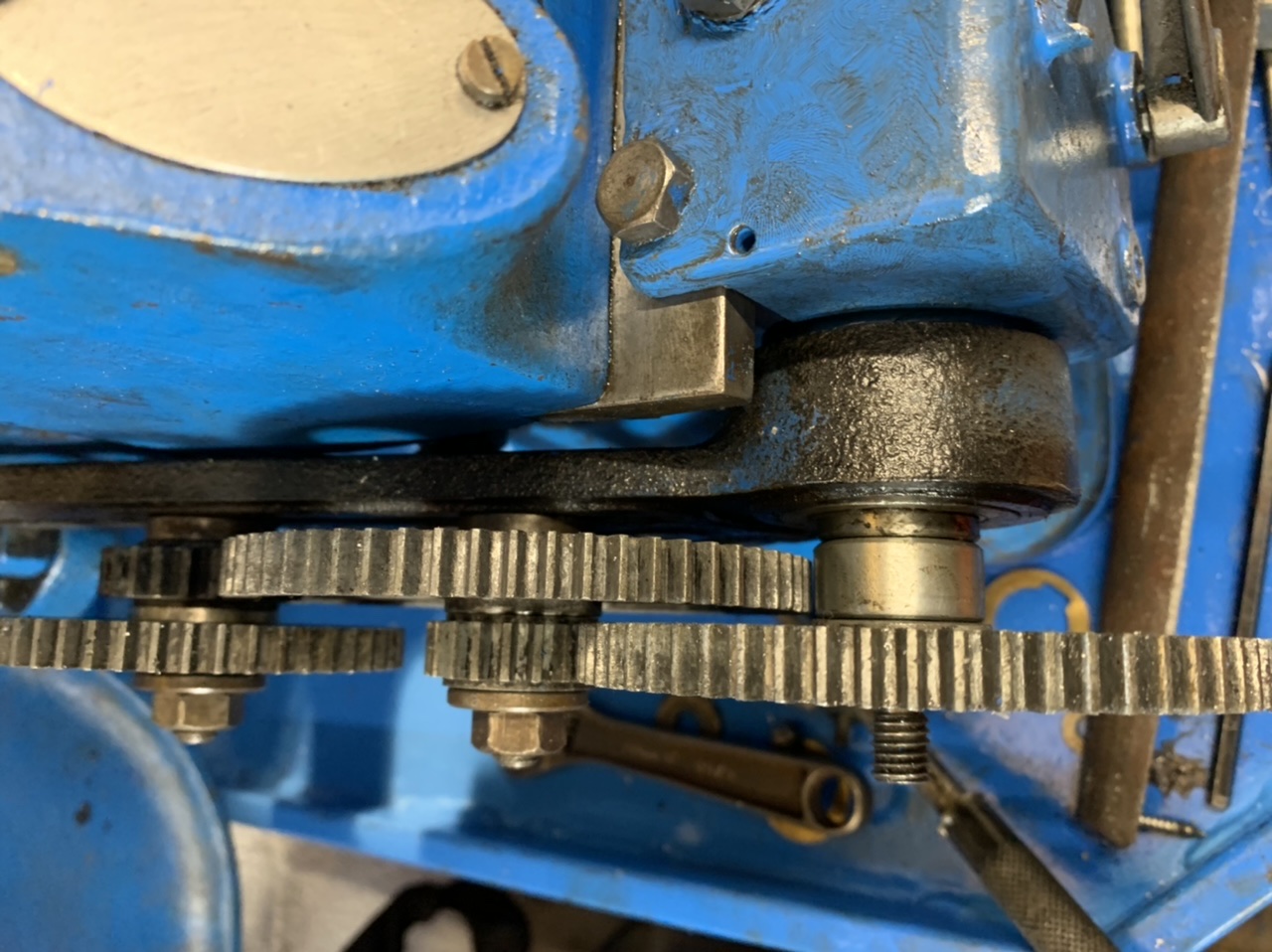

Fitted my gearbox, then made a few spacers to align the transfer gears correctly then when to fit the screw gear and found my stub shaft had been turned down to fit the homemade gearbox!! Not a problem, I managed to swap the stubs over but keep the unmarked bevel gear as it was roll pinned.

Working fine. I’ll post a vid in a bit.

Next repair is the saddle backlash.

Working fine. I’ll post a vid in a bit.

Next repair is the saddle backlash.

Exuptoy

Member

- Messages

- 2,933

- Location

- Maesteg, South Wales

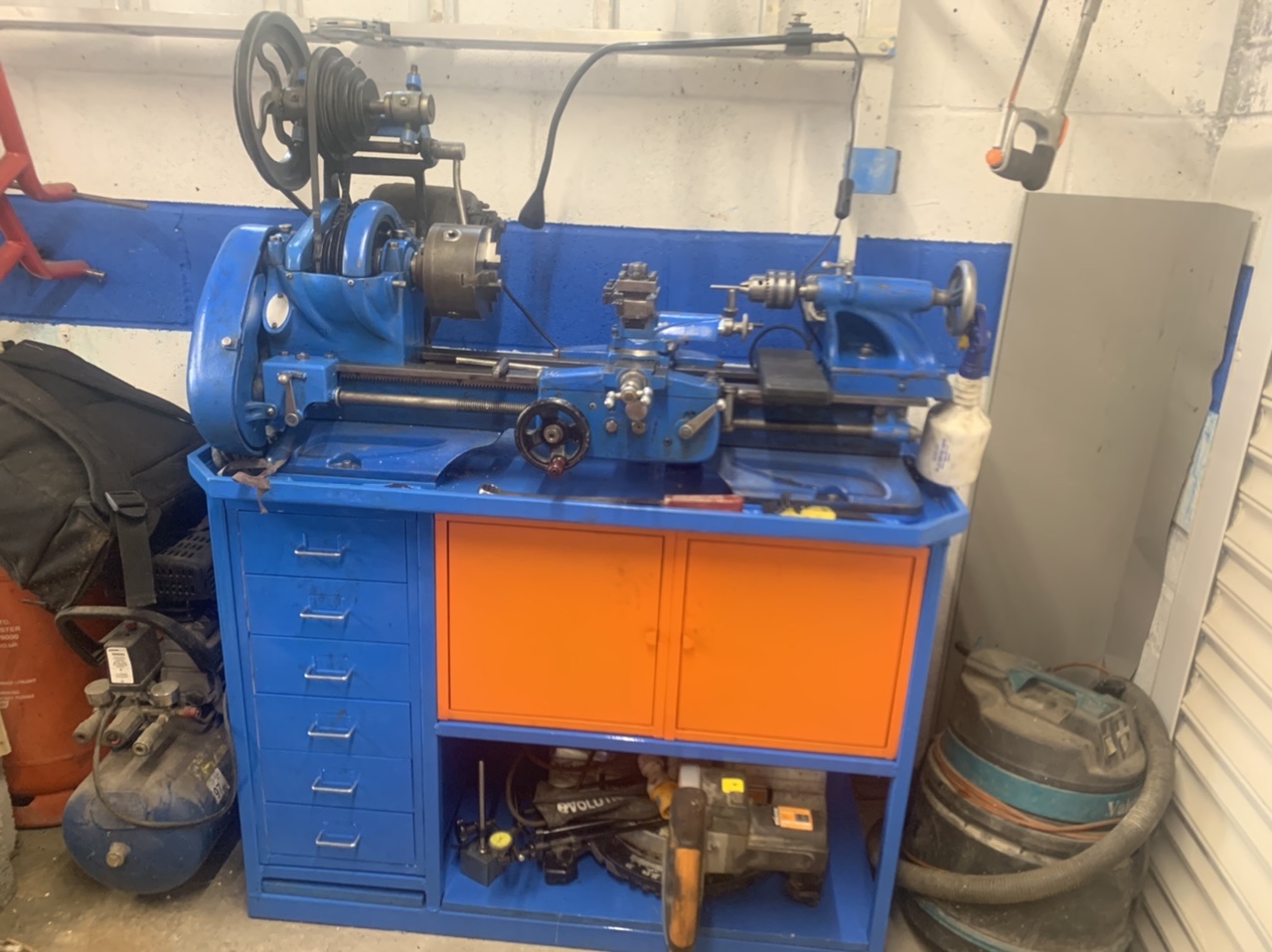

Following repairing the gearbox I fitted the bull gear pin and detent / spring but first I managed to turn drop the spring inside the pulley, which caused me some consternation, so I made the decision to remove the head and retrieve the spring.

Whilst off I decided to use Mike Kurns’ original new old stock bull gear pin with detent feature as it was longer than my one which seems to have been made to fit. I’ve told Mike he can have the spare pin as it does work and when spares dry up he will at least have another spare for someone who is desperate.

Next up was the saddle, I removed the apron and immediately found the gear housing was snapped but still sat in the same position it should be due to its dowel pins. I replaced the gears and shaft as I had intended but also managed to stick the 2 parts together with my Tig . I say stick it together as it was clearly not welded! (I can tell you that it’s either cast or Zamak and it didn’t like being welded! It was fizzing and giving off a white residue on my torch). I have dropped Mike a line as he has a spare gear case for £32.

I will at least have piece of mind then that all is well inside.

Anyway, all in all I now have a lathe which is in rude health and does all it should with no backlash in the carriage and runs fairly quiet, but that’s not to say I won’t buy more parts to refine it even further and get rid of any evidence of it having seen much work in the past.

Whilst off I decided to use Mike Kurns’ original new old stock bull gear pin with detent feature as it was longer than my one which seems to have been made to fit. I’ve told Mike he can have the spare pin as it does work and when spares dry up he will at least have another spare for someone who is desperate.

Next up was the saddle, I removed the apron and immediately found the gear housing was snapped but still sat in the same position it should be due to its dowel pins. I replaced the gears and shaft as I had intended but also managed to stick the 2 parts together with my Tig . I say stick it together as it was clearly not welded! (I can tell you that it’s either cast or Zamak and it didn’t like being welded! It was fizzing and giving off a white residue on my torch). I have dropped Mike a line as he has a spare gear case for £32.

I will at least have piece of mind then that all is well inside.

Anyway, all in all I now have a lathe which is in rude health and does all it should with no backlash in the carriage and runs fairly quiet, but that’s not to say I won’t buy more parts to refine it even further and get rid of any evidence of it having seen much work in the past.

Arc Tourist

Member

- Messages

- 4,923

- Location

- Wales

A match book cover or business card is about the right thickness for clearance.

Exuptoy

Member

- Messages

- 2,933

- Location

- Maesteg, South Wales

Cheers guys. It is quieter now. I found the back gear RH gear had moved over and was grinding in the RH cover. After removing the head to split the bull gear from the pulley to retrieve my spring everything is back where it should be it’s quiet now. Still noisy in back gear but pretty quiet in high speed on Ally. I’ll do another vid tomorrow. I’ll check the gears at the same time just to be sure.

Thanks.

Thanks.

Gritineye

Member

- Messages

- 2,058

Glad you've got it sorted, i've tried most things to lube and quieten the change gears, and what i use now is the treacle like 600w gear oil I drained out of my 1928 Chevy gearbox, almost silent now, but the chip tray underneath is proper messy.

Yes, I did let the oil settle for a month.

Ignore all those pristine oil free restored lathes on the web, lube is your friend and your Atlas will thank you for it, so give it plenty.

Yes, I did let the oil settle for a month.

Ignore all those pristine oil free restored lathes on the web, lube is your friend and your Atlas will thank you for it, so give it plenty.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,342

- Location

- NE London - UK

If you use the change wheels you should lubricate them. A sticky molybdenum Disulphide grease such as Molyslip OCL is perfect, although expensive. Normal motorcycle chain lube is probably adequate for your needs.

Gritineye

Member

- Messages

- 2,058

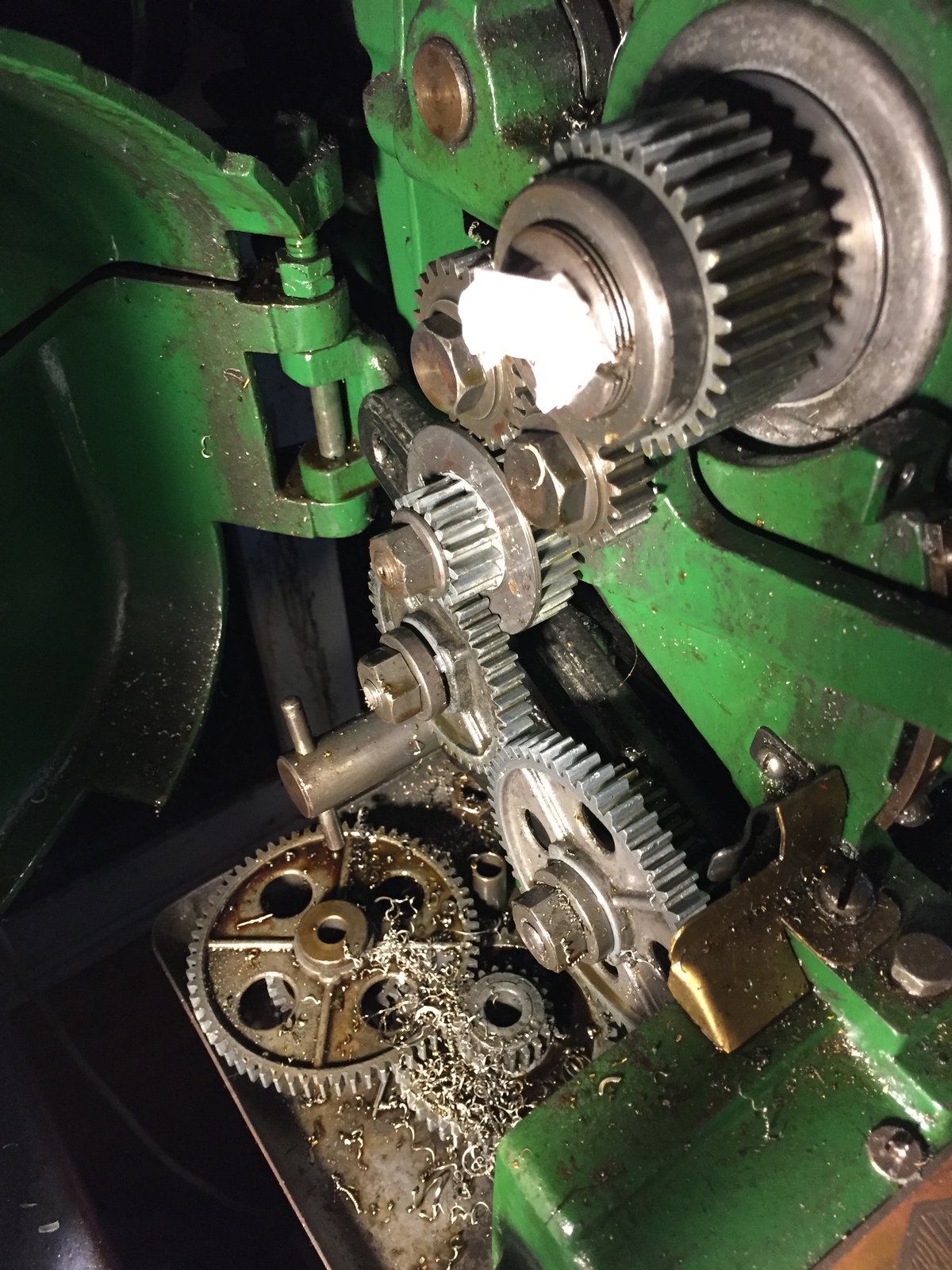

Here's a good tip, always plug the end of your spindle.

Just had a peep at the state of my lathes oilyness, it's actually not quite so bad as usual, but just look at the chips/swarf that's found it's way out of the end of the spindle bore.

I keep it plugged but had forgotten after turning a long rod the other day, and have been making lots of chips today, this will do more damage to the Zamak gears than anything else,

.

.

Just had a peep at the state of my lathes oilyness, it's actually not quite so bad as usual, but just look at the chips/swarf that's found it's way out of the end of the spindle bore.

I keep it plugged but had forgotten after turning a long rod the other day, and have been making lots of chips today, this will do more damage to the Zamak gears than anything else,