zx9

Forum Supporter

- Messages

- 5,182

- Location

- South East London

Yes it works fine, I liked the post after watching your vid.Does the link work for anyone because it won't for me

Yes it works fine, I liked the post after watching your vid.Does the link work for anyone because it won't for me

Yes but you have to copy and paste then delete the vidio bit.

Here it is for you to save having to do that.

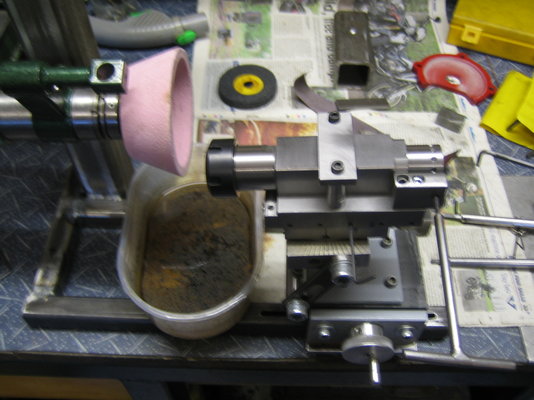

Forgot to take picturesbut had to machine 2 new shaft ends for a Westwood powered grass collector sweeper today. The bearings on both ends of the shaft were goosed. The pulley side was so bad there were no balls left in the bearing and it had obviously been run like this for some time as the shaft end was extremely worn. (Note I got the sweeper unit 2nd hand for £30, so worth taking the time to repair). An hour later and I had 2 shaft ends machined up on the lathe. I then had to grind off the weld on the outside of the pulley to remove the worn shaft end and a good pressed in fit for the new shaft end was achieved and welded for good measure.

It was a very poor design and as you discovered it is a faff to change them. We didn't have a lathe so it was a matter of building up a worn shaft with weld & 'machining' it to size with an angle grinder!

It was a very poor design and as you discovered it is a faff to change them. We didn't have a lathe so it was a matter of building up a worn shaft with weld & 'machining' it to size with an angle grinder!

Thanks, it's coming along.That's a work of art Richardm

Nicely done and I love seeing things like this because it reminds me why I don't do production stuff......... only another 1650 holes to go! .......

To me that is a very patient man loading the machine, to heck with that

Nicely done and I love seeing things like this because it reminds me why I don't do production stuff.

To me that is a very patient man loading the machine, to heck with that