- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

mtt.tr

Member

- Messages

- 8,433

- Location

- Essex/Suffolk border

some switchgear for my bike build...

View attachment 199838 View attachment 199839 View attachment 199840

Smart

Now you need in bar cables

lchris21

Member

- Messages

- 1,973

- Location

- South Wales

thats what the slot in the side is forSmart

Now you need in bar cables

Kram

Member

- Messages

- 7,150

- Location

- Sussex

That saying, "Dont put your fingers where you wouldnt put your dick". Well applies to face too. Leaning into the gap behind to fit chip guard and a ccmt tool twatted me in the lip.

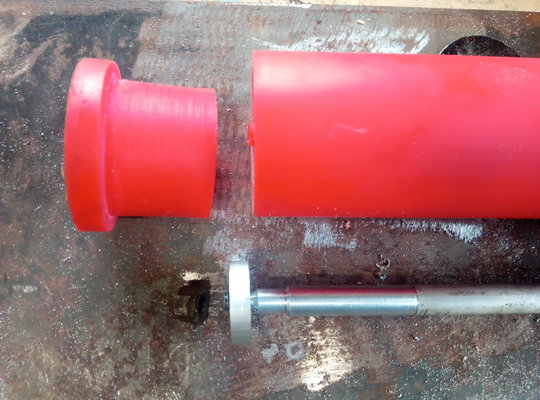

First chips in ages. Boring out a 3" lump to be spindle pulley/hub for the 110mm and 180mm pulleys.

First chips in ages. Boring out a 3" lump to be spindle pulley/hub for the 110mm and 180mm pulleys.

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Lathe. New motor and pulleys.Going on from your wanted thread...can i ask what are you making of fixing with stepped pullys?

https://www.mig-welding.co.uk/forum/threads/new-motor-and-vfd.95777/page-2#post-1444458

Kram

Member

- Messages

- 7,150

- Location

- Sussex

Rough atttempt at a pulley. Started cutting right side angle by compound and the rest is rough.

Problem being, without a tool angled under 38? degrees, wont have clearance enough to sweep the bottom. Should I start with a square groove tool to full depth, and then cut the angles, until they intersect?

Problem being, without a tool angled under 38? degrees, wont have clearance enough to sweep the bottom. Should I start with a square groove tool to full depth, and then cut the angles, until they intersect?

ronan

Member

- Messages

- 11,399

Rough atttempt at a pulley. Started cutting right side angle by compound and the rest is rough.

Problem being, without a tool angled under 38? degrees, wont have clearance enough to sweep the bottom. Should I start with a square groove tool to full depth, and then cut the angles, until they intersect?

Yes, i always plunge with a parting off tool, get the bulk of the material out of the way and give yourself a bit of room to work.

slim_boy_fat

Member

- Messages

- 29,540

- Location

- Scottish Highlands

Just to make some stainless sleeves and its done. Hopefully Only an hour left

You going to knit a jumper?

.

.

mtt.tr

Member

- Messages

- 8,433

- Location

- Essex/Suffolk border

Hood

I am obsessed.

- Messages

- 17,399

- Location

- Carnoustie, Scotland

I have only ever machined it once and thought it was quite nice to machine, maybe a different grade or something. I used a DNMG insert but it was actually a HSS insert, polished and very sharp with a positive rake.Horrible bloody stuff.

mtt.tr

Member

- Messages

- 8,433

- Location

- Essex/Suffolk border

I have only ever machined it once and thought it was quite nice to machine, maybe a different grade or something. I used a DNMG insert but it was actually a HSS insert, polished and very sharp with a positive rake.

If im honest this stuff was pretty easy, just ground a hss blank very positive rake finsh was good. I have machined softer poly and that really is awful as it just doesn't want to come away.

I also find deep depth of cut high speed infeed and fast spindle speed using stabbing moves forces the poly to break away from it self, continuous cuts it get pushed along in a complete ring

Oh and wood spade drills are the nuts for drilling it

Its more akin to wood turning.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,530

- Location

- Keeler crater

I've tried that once, I found it worked much better using the more rigid rear toolpost, tightening the gibs on the compound would have probably helped too.You can do the keyway on the lathe too if you don't have broaches and a press. Using the carriage like a shaper.