- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Kram

Member

- Messages

- 7,417

- Location

- Sussex

Preload adjustment for spindles is an art, the second bearings are too tight fit to make it easy. I couldnt find if theres a factory process/method for it, or if it just needs more experience.

With my lathe spindle, a few on here suggested easing the fit for the rear bearing as they tend to jump from loose to too tight.

With my lathe spindle, a few on here suggested easing the fit for the rear bearing as they tend to jump from loose to too tight.

The manual for my Town Woodhouse mill suggested the preload was adjusted “a little”.Preload adjustment for spindles is an art, the second bearings are too tight fit to make it easy. I couldnt find if theres a factory process/method for it, or if it just needs more experience.

With my lathe spindle, a few on here suggested easing the fit for the rear bearing as they tend to jump from loose to too tight.

Pete.

Member

- Messages

- 14,575

- Location

- Kent, UK

Turned a couple of axles to give some podium steps at work a new lease of life. The old tube aaxles had fallen out ages ago and people stopped using them. It so happens that they are perfect for my work so it was worth the hour of turning them out of steel then oil-blackening them so they don't rust too quickly.

Rannsachair

Forum Supporter

- Messages

- 4,107

- Location

- Lochgilphead, Argyll, Republic of Scotland

Turned this tap adaptor in stainless a while ago:

now fitted, filled a gapthat allowed tap to push through worktop on daughter in laws mum's sink:

Father in law asked for some 2 penny washers:

And took a skim of the damaged anvil on my swinden and welded up and spot faced mounting feet.

now fitted, filled a gapthat allowed tap to push through worktop on daughter in laws mum's sink:

Father in law asked for some 2 penny washers:

And took a skim of the damaged anvil on my swinden and welded up and spot faced mounting feet.

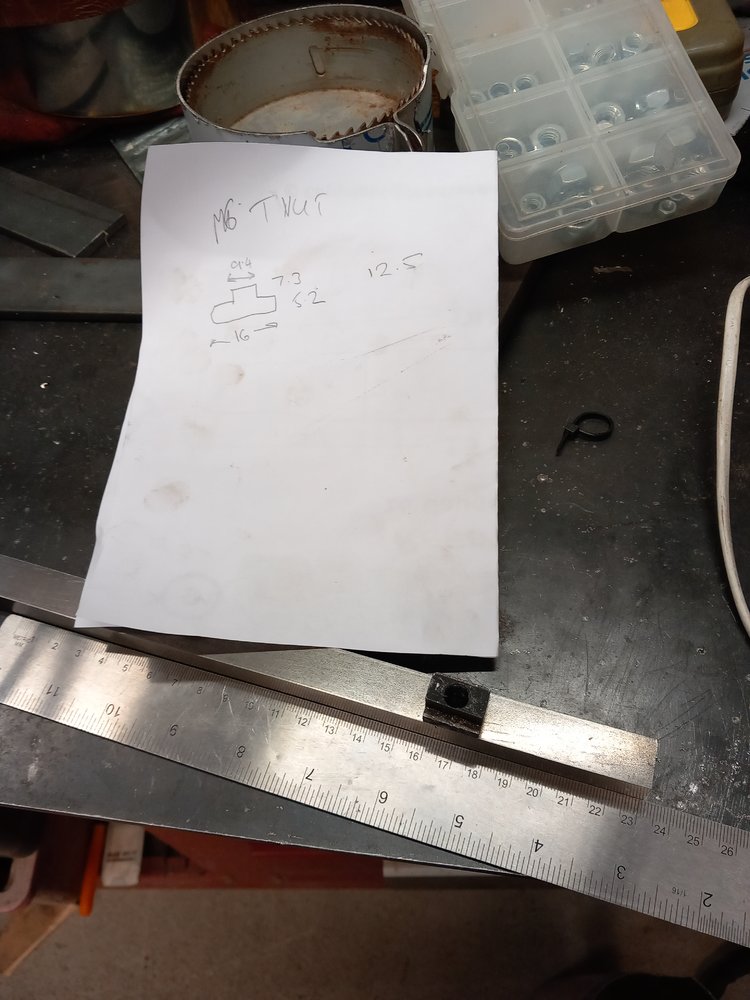

I'm having a go at making some t-nuts with an M6 metric thread. From memory, the set on my mill are nominally 3/8" top slot with a 5/16ths thread.

I want the smaller metric thread so I can mount my work using holes already found in the work piece design. It needs bolting to an adjustable angle plate. There will be a sacrificial spacer to prevent the apprentice marks.

Rough dimensions measured and rounded up as the T nuts that I have seem to be a bit on the small side. I know we don't want them getting stuck, but they seem a rather slack fit.

I've bought some 16mm square bar so my bottom dimension is already done. The black t-nut sat on the bar is a shoddy Chinese one that I'm trying to replicate.

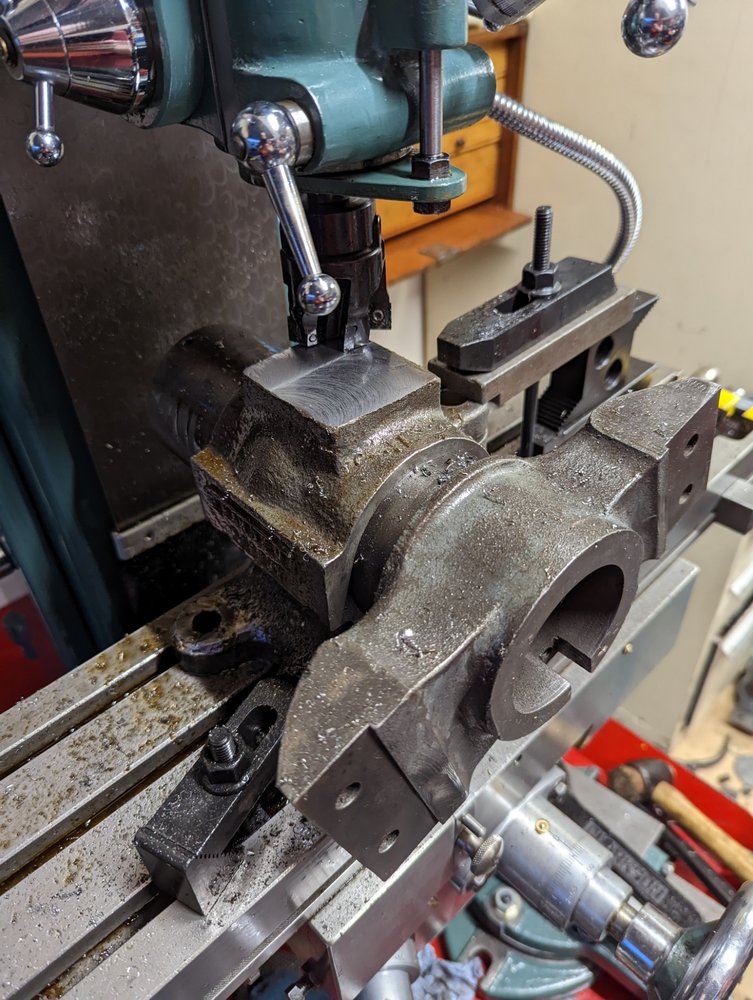

Bar set up on the mill. There's a lot of spare material at the top that I used to finesse my cutting in from the side. The top 3.5mm will be removed so if I cut too far towards the centre it didn't matter. I used an edge finder and my DRO but still needed to make adjustments. Possibly a worn end mill or flex in my shoddy set up. I got it dialled in before I ran out of depth.

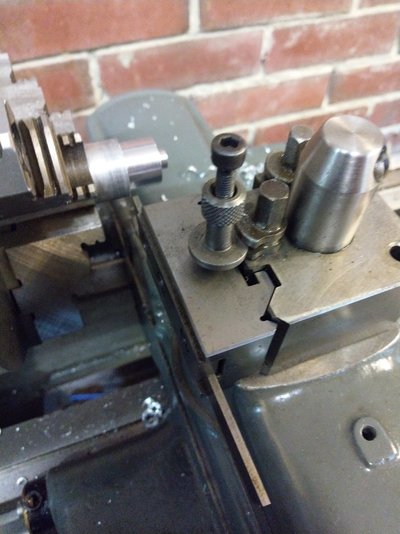

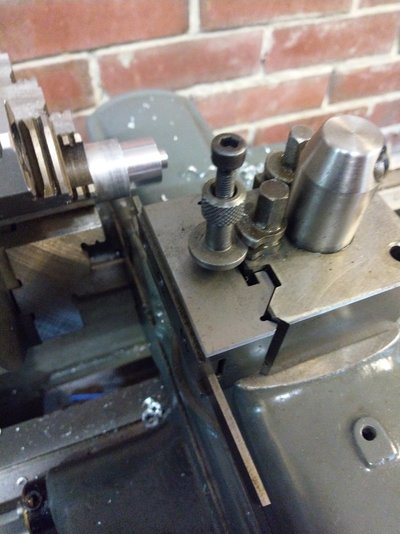

A quick comparison as I go along. Getting there. The T-nuts are a slack fit so as long mine aren't any smaller there is plenty of leeway.

I've milled enough material to make three. I only need two. Stick out from the vice was bad enough without trying for more. This was a fair bit of work for me. I was taking a half mm depth of cut over 3.3mm wide. Lots of passes. A bigger machine would make short work of this, but it's a bit of a slog on a small mill.

Just need to cut in the bandsaw, drill and tap.

I want the smaller metric thread so I can mount my work using holes already found in the work piece design. It needs bolting to an adjustable angle plate. There will be a sacrificial spacer to prevent the apprentice marks.

Rough dimensions measured and rounded up as the T nuts that I have seem to be a bit on the small side. I know we don't want them getting stuck, but they seem a rather slack fit.

I've bought some 16mm square bar so my bottom dimension is already done. The black t-nut sat on the bar is a shoddy Chinese one that I'm trying to replicate.

Bar set up on the mill. There's a lot of spare material at the top that I used to finesse my cutting in from the side. The top 3.5mm will be removed so if I cut too far towards the centre it didn't matter. I used an edge finder and my DRO but still needed to make adjustments. Possibly a worn end mill or flex in my shoddy set up. I got it dialled in before I ran out of depth.

A quick comparison as I go along. Getting there. The T-nuts are a slack fit so as long mine aren't any smaller there is plenty of leeway.

I've milled enough material to make three. I only need two. Stick out from the vice was bad enough without trying for more. This was a fair bit of work for me. I was taking a half mm depth of cut over 3.3mm wide. Lots of passes. A bigger machine would make short work of this, but it's a bit of a slog on a small mill.

Just need to cut in the bandsaw, drill and tap.

Johnnybravo

Member

- Messages

- 3,639

- Location

- Northiam

Clamp it in the vice on top of parallels next time and it will be infinitely easier. Avoid long hang outs like that, like the plague…I'm having a go at making some t-nuts with an M6 metric thread. From memory, the set on my mill are nominally 3/8" top slot with a 5/16ths thread.

I want the smaller metric thread so I can mount my work using holes already found in the work piece design. It needs bolting to an adjustable angle plate. There will be a sacrificial spacer to prevent the apprentice marks.

Rough dimensions measured and rounded up as the T nuts that I have seem to be a bit on the small side. I know we don't want them getting stuck, but they seem a rather slack fit.

I've bought some 16mm square bar so my bottom dimension is already done. The black t-nut sat on the bar is a shoddy Chinese one that I'm trying to replicate.

View attachment 363045

Bar set up on the mill. There's a lot of spare material at the top that I used to finesse my cutting in from the side. The top 3.5mm will be removed so if I cut too far towards the centre it didn't matter. I used an edge finder and my DRO but still needed to make adjustments. Possibly a worn end mill or flex in my shoddy set up. I got it dialled in before I ran out of depth.

View attachment 363047

A quick comparison as I go along. Getting there. The T-nuts are a slack fit so as long mine aren't any smaller there is plenty of leeway.

View attachment 363046

View attachment 363048

I've milled enough material to make three. I only need two. Stick out from the vice was bad enough without trying for more. This was a fair bit of work for me. I was taking a half mm depth of cut over 3.3mm wide. Lots of passes. A bigger machine would make short work of this, but it's a bit of a slog on a small mill.

Just need to cut in the bandsaw, drill and tap.

View attachment 363049

View attachment 363050

Wedg1e

They call me Mr. Bodge-angles

- Messages

- 7,735

- Location

- Teesside, England

RichieW, climb-milling with that bar stuck out the side of the vice that far...

I should imagine it rattled like the bones of a Stockton crack-hooker.

I keep meaning to make some T-nuts for my ancient Perrin drill; I keep on monkeying it with an assortment of lengths of studding and whatever nuts will slide into the grooves

I should imagine it rattled like the bones of a Stockton crack-hooker.

I keep meaning to make some T-nuts for my ancient Perrin drill; I keep on monkeying it with an assortment of lengths of studding and whatever nuts will slide into the grooves

Agroshield

Member

- Messages

- 5,698

...a Stockton crack-hooker.

I keep meaning to make some T-nuts...

Are they the ones who come around to your place and dig the weeds out of the gaps in the crazy paving with a bent implement?

Lazy T-nuts can be made from Unistrut zebedees. Easy to size with a belt sander.

dobbslc

Forum Supporter

- Messages

- 12,417

- Location

- Hertfordshire UK

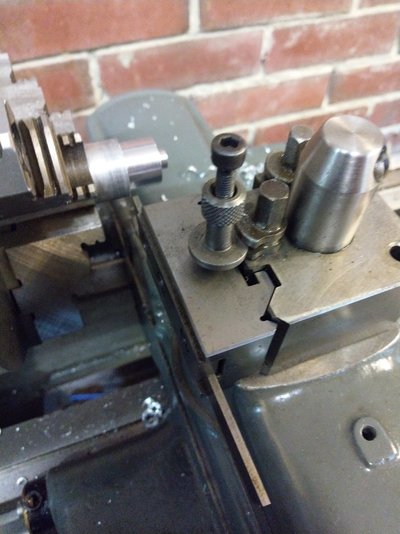

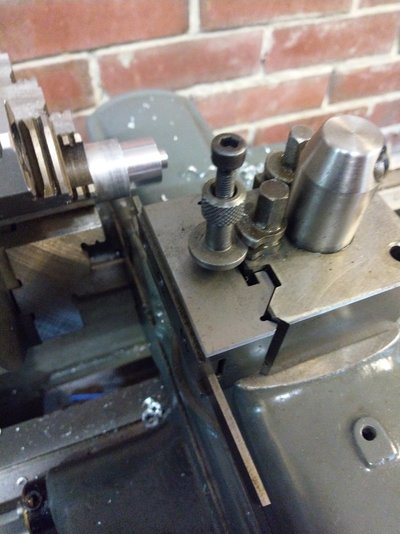

Some serious work needed doing today so I fired up the South Bend lathe.

The locating pin on the bog roll holder has snapped off causing the roll to fall out at the worse possible time.

I chucked it up, it took ages to get dialed in, I don't want too much run out due to the high speed it'll have to work at on the morning after the night before...

Bored out the center and faced it off.

I used a piece of aloominum to make a new pin.

Parted it off but the tool was miles below center and I couldn't get it adjusted correctly so just left the parting tool cam above the locking clamp. I'll need to sort this out later.

Piece turned and inserted into the bog roll holder and fixed with some UHU, I love the smell of UHU!

I presented this to my wife and she seemed quite pleased

It will be replaced when the bathroom eventually gets refurbed but just has to last a bit longer.

The locating pin on the bog roll holder has snapped off causing the roll to fall out at the worse possible time.

I chucked it up, it took ages to get dialed in, I don't want too much run out due to the high speed it'll have to work at on the morning after the night before...

Bored out the center and faced it off.

I used a piece of aloominum to make a new pin.

Parted it off but the tool was miles below center and I couldn't get it adjusted correctly so just left the parting tool cam above the locking clamp. I'll need to sort this out later.

Piece turned and inserted into the bog roll holder and fixed with some UHU, I love the smell of UHU!

I presented this to my wife and she seemed quite pleased

It will be replaced when the bathroom eventually gets refurbed but just has to last a bit longer.

MattF

Forum Supporter

- Messages

- 16,931

- Location

- South Yorkshire

Tigman

Forum Supporter

- Messages

- 3,845

- Location

- Watford UK

A little advice please I'm roughing out a bit of aluminium , it's an extention for an exercise bike saddle , I set the head of the mill to 9 degrees and am using a fly cutter to get it down to size , question is why does the fly cutter cut twice , hence the circle on the piece , it doesnt make sense to me , even on a very fine feed I won't get a finish , any ideas

m

m

m

m

Stood infront of lathe for an hour tidying as couldnt think of anything to turn.

Stood infront of lathe for an hour tidying as couldnt think of anything to turn.