- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- CAD/CAM, 3D Printing and Laser Cutting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anet A8 3D Printer.

- Thread starter ukracer

- Start date

Thats the stuff that takes time to learn and implement. If you make assumptions they are not always correct. For example in octoprint there is a box that says motors off...which I thought would disable steppers....but it doesnt on mine..lolThere's an extraneous G92 in there but it's because I didn't used to have extruder motor hold on and springy stuff like nylon would push the gear back, you don't need both.

Finally got my new printer, took about 30 mins to assemble, 5 mins to set up, 5 mins to start my first print and about another 10 minutes to now think I should have purchased a bigger one!

Not sure how the slicer works out the nozzle path, it seems a little odd and inefficient at times?

Not sure how the slicer works out the nozzle path, it seems a little odd and inefficient at times?

Wait till you start printing and see how long it actually takes...lolFinally got my new printer, took about 30 mins to assemble, 5 mins to set up, 5 mins to start my first print and about another 10 minutes to now think I should have purchased a bigger one!

Not sure how the slicer works out the nozzle path, it seems a little odd and inefficient at times?

IMHO having just started you are better to get a smaller machine while learning for various reasons not least errors will be exaggerated and temptation to build bigger models straight away will use more time and filament especially if you get errors.

PLUS if you need a larger one you have the small one for any smaller jobs while the larger one is tied up for days.

I have just been offered a Geeetech A30 for under £350 so i am selling my last two vinyl cutters and shifting the rest of my Tshirts to fund the purchase ...

I just had one guy ask me for 5 shirts with

Its back...

HAMMER TIME

out of the blue. I had them advertised on facebook for a fiver and not had one sale in 3 months....strange just when i need the money i get asked...now to find my heat press out.

Wait till you start printing and see how long it actually takes...lol

IMHO having just started you are better to get a smaller machine while learning for various reasons not least errors will be exaggerated and temptation to build bigger models straight away will use more time and filament especially if you get errors.

PLUS if you need a larger one you have the small one for any smaller jobs while the larger one is tied up for days.

I have just been offered a Geeetech A30 for under £350 so i am selling my last two vinyl cutters and shifting the rest of my Tshirts to fund the purchase ...

I just had one guy ask me for 5 shirts with

Its back...

HAMMER TIME

out of the blue. I had them advertised on facebook for a fiver and not had one sale in 3 months....strange just when i need the money i get asked...now to find my heat press out.

There is another 10% off Ebay today which may work out cheaper?

I am now trying a 0.8mm nozzle to see if it works or not, should reduce the print time but not sure if it will stick to the bed, may try a 0.6mm after

How did you find out about the 10% off.There is another 10% off Ebay today which may work out cheaper?

I am now trying a 0.8mm nozzle to see if it works or not, should reduce the print time but not sure if it will stick to the bed, may try a 0.6mm after

How did you find out about the 10% off.

They normally email some people each time they do it, then at times they display it on their home page - but not always

I thought that would be the case...thanks for confirming mate.Everywhere, otherwise the arms won't be supported.

It was actually 13 hours as cura lied again. BUT i had a real piece of bad luck.

Apart from not getting it flat in cura (meaning it built a raft under part of the base) i had an un finished model with spaghetti sitting there in the morning)

Investigation showed a round head screw stuck to part of the plastic spaghetti.

The screw had actually come from my hot end. Has anyone else had /seen/heard of this happening before.?

My guess is that had it not stuck it might have completed..........but whilst cura said 100% it also said a few seconds left and the time lapse did not save, which is annoying as it might have confirmed what actually happened.

Apart from not getting it flat in cura (meaning it built a raft under part of the base) i had an un finished model with spaghetti sitting there in the morning)

Investigation showed a round head screw stuck to part of the plastic spaghetti.

The screw had actually come from my hot end. Has anyone else had /seen/heard of this happening before.?

My guess is that had it not stuck it might have completed..........but whilst cura said 100% it also said a few seconds left and the time lapse did not save, which is annoying as it might have confirmed what actually happened.

on the older version you click on the model then click "lie flat"How do you make sure the base of a model is actually flat on the base using cura?

The screw had actually come from my hot end. Has anyone else had /seen/heard of this happening before.?

I have had mine come loose (I noticed before something dropped off, but only just). For me I suspect it was over extrusion, as the nozzle went back over he workpiece it would clip some of the previous layer - I then found out for PLA you should typically set the flow rate to 90% and then adjust depending upon any remaining over / under extrusion

Print times in Cura are out for my prints as well, but I think this is because my speed settings in Cura are not achieved by either Octoprint or the printer as it slows down for detail areas, sometimes to a very low speed to maintain the quality of print (better than blasting through them and making a mess)

DAPPH

as dyslexik as I'm daft

- Messages

- 7,301

- Location

- Near to Cross Hands Llanelli SouthWales GB

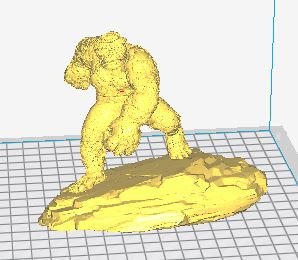

And then there's foundry work: 3d print the pattern, cast it in aluminium

Been thinking of making a 3D three or four piece mould for making an injected wax form and then doing a tree of six lost wax castings in brass.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,301

- Location

- Near to Cross Hands Llanelli SouthWales GB

Oh dear what have you guys done? Pandora's box is now open.

I spent the last few hours reading the thread hoping I'd find some useful names & to get and insight into 3D printing. As you can see I've got to Hoods post # 236. Then the rot's set in, I signed up to " Onshape " & started the tutorial.

I've suddenly discovered the world I've been seeking for about 15 years. When I got a supposedly quality garden designing programme for extortionate price of about £ 35, but my computer memory & speed was not up to handling it so it got dropped as it wouldn't run on my next new bigger better spec computer.

Same thing happened with a 3D self design house build programme . I had all the details for a four double bedroomed bungalow with external workshop , got it down to the type of front door & it all crashed time & time again, all due to computer related technical problems and stone aged internet speeds. BT's recent uplift to a digital cabinet 200 mtrs away has settled down and teething problems have been ironed out … things connection are taking off.

Santa in Fishnets sent an elf back at 21.00 hrs., bearing good news for what appears to be a decent printer a , " FLSUN 3D Printer plus Prusa i3 diy kit, dual nozzle ". It's soon to be ordered & put on his sledge ", unless of course the guys on here start screaming don't do it Dave . (

Speak now or forever hold your piece

Speak now or forever hold your piece  ).

).I'm now going to read the rest of this thread to see what else I can glean besides that, " Using filaments with the variable appearance & lumpy measurements of a pearl bead necklace ain't going to be conclusive to getting an even thickness to the layer of plastic being deposited from the printing head.

One question , putting the glass on the table /base, Is shop window plate glass at say 8 to 10 mm mm thick or so OK ?

Dave

Last edited:

Wendelspanswick

Member

- Messages

- 6,471

You need borscilate glass as it's heat resistant.Oh dear what have you guys done? Pandora's box is now open.

I spent the last few hours reading the thread hoping I'd find some useful names & to get and insight into 3D printing. As you can see I've got to Hoods post # 236. Then the rot's set in, I signed up to " Onshape " & started the tutorial.

I've suddenly discovered the world I've been seeking for about 15 years. When I got a supposedly quality garden designing programme for extortionate price of about £ 35, but my computer memory & speed was not up to handling it so it got dropped as it wouldn't run on my next new bigger better spec computer.

Same thing happened with a 3D self design house build programme . I had all the details for a four double bedroomed bungalow with external workshop , got it down to the type of front door & it all crashed time & time again, all due to computer related technical problems and stone aged internet speeds. BT's recent uplift to a digital cabinet 200 mtrs away has settled down and teething problems have been ironed out … things connection are taking off.

Santa in Fishnets sent an elf back at 21.00 hrs., bearing good news for what appears to be a decent printer FLSUN 3D Printer plus Prusia i3 diy kit, dual nozzle, ". It's soon to be ordered &put on his sledge ", unless of course the guys on here start screaming don't do it Dave . (Speak now or forever hold your piece

).

I'm now going to read the rest of this thread to see what else I can glean besides that, " Using filaments with the variable appearance & lumpy measurements of a pearl bead necklace ain't going to be conclusive to getting an even thickness to the layer of plastic being deposited from the printing head.

One question , putting the glass on the table /base, Is shop window plate glass at say 8 to 10 mm mm thick or so OK ?

Dave

A 200mm square is about a tenner posted.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,301

- Location

- Near to Cross Hands Llanelli SouthWales GB

One more question .

For:- flsun 3d printer plus prusa i3 diy kit, dual nozzle.

The filaments are on reels, I cant see any reel holders for them in the pretty pictures . Do you normally have to make your own reel stand and fit it to a wall or make it a free standing unit that can be stood very close to the machine ?

For:- flsun 3d printer plus prusa i3 diy kit, dual nozzle.

The filaments are on reels, I cant see any reel holders for them in the pretty pictures . Do you normally have to make your own reel stand and fit it to a wall or make it a free standing unit that can be stood very close to the machine ?