- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- CAD/CAM, 3D Printing and Laser Cutting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anet A8 3D Printer.

- Thread starter ukracer

- Start date

Mine is an ender 3 with Marlin firmware. So might be different. But from what I have read it sounds like the baby stepping is the same. It's designed so you can lower nozzle while printing after you have levelled the bed and set zero to adjust on the fly. whilst printing and seeing the actual squish..Taking a video is possible , I've not put one on a site though .. still you're not dead till you stop breathing so it's a possibility for me.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Yes , I feel it needs to be water resisting as it will be wetted most days twice in 24 hrs for 2 min at a time throughout the watering seasons.IIRC ABS is bad for warping, and where heated enclosures make a big difference.

Do you really need to use ABS?

It is to be a small bracket ... a closed off hole that will slip over an 8 mm stick of fibre glass rod at one end and at the other a sort of c opening into which I will press a 6.4 mm butyl water line that holds the misting spray heads for my garden & greenhouse irrigation system . I need 60 plus at the end of the day then another 40 or so in a different size.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Yep it is flattening the extruded ABS well & trulyMine is an ender 3 with Marlin firmware. So might be different. But from what I have read it sounds like the baby stepping is the same. It's designed so you can lower nozzle while printing after you have levelled the bed and set zero to adjust on the fly. whilst printing and seeing the actual squish..

So if it is lowering the nozzle and it's wrecking things then resetting the PINDA to a higher 0.5 mm higher then trying to set the Z & then fine adjust should be useful , but I'll have to do it very very carefully as I don't want to kill the bed with any bed crashes .

I didn't get on with the new drawing / design as intended .. got side tracked with a silver blond called " Wife " .

PETG should handle being wet. It does absorb water, but it doesn't affect it's lifespan like it does PLA.Yes , I feel it needs to be water resisting as it will be wetted most days twice in 24 hrs for 2 min at a time throughout the watering seasons.

It is to be a small bracket ... a closed off hole that will slip over an 8 mm stick of fibre glass rod at one end and at the other a sort of c opening into which I will press a 6.4 mm butyl water line that holds the misting spray heads for my garden & greenhouse irrigation system . I need 60 plus at the end of the day then another 40 or so in a different size.

But even PLA would probably even last a while in that situation as well.

If you've not got any PETG and would like a few printed to test, send me over the file and I'll print a few so you can test them.

daedalusminos

Member

- Messages

- 2,401

- Location

- Norwich

I've not had any problems with the PINDA, it needs to be low enough to give a good consistent signal then use the Z adjust to set your first layer height.So if it is lowering the nozzle and it's wrecking things then resetting the PINDA to a higher 0.5 mm higher then trying to set the Z & then fine adjust should be useful , but I'll have to do it very very carefully as I don't want to kill the bed with any bed crashes .

With regards ABS, I assume you're using the smooth flexi plate? I tend to clean with IPA by spraying it directly on to the plate then wipe dry (cold) with a lint free cloth. ABS will pull off the bed due to shrinkage on upper layers but that can be minimised with a raft and also by part geometry...think about printing a truncated cone (not the pointy bit), if you print with large diameter on the bed then all the forces are transmitted straightto the first layer and it will be liable to detach. If you print small diameter on the bed the the shrinkage tends to be absorbed in the structure.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Lets see if this worksPETG should handle being wet. It does absorb water, but it doesn't affect it's lifespan like it does PLA.

But even PLA would probably even last a while in that situation as well.

If you've not got any PETG and would like a few printed to test, send me over the file and I'll print a few so you can test them.

'Arghh ..no it didn't.

Well at least I tried

Well at least I tried

Yes please that would be very kind of you ..where do I send it ? PM me your email please ?PETG should handle being wet. It does absorb water, but it doesn't affect it's lifespan like it does PLA.

But even PLA would probably even last a while in that situation as well.

If you've not got any PETG and would like a few printed to test, send me over the file and I'll print a few so you can test them.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

I've not had any problems with the PINDA, it needs to be low enough to give a good consistent signal then use the Z adjust to set your first layer height.

With regards ABS, I assume you're using the smooth flexi plate? I tend to clean with IPA by spraying it directly on to the plate then wipe dry (cold) with a lint free cloth. ABS will pull off the bed due to shrinkage on upper layers but that can be minimised with a raft and also by part geometry...think about printing a truncated cone (not the pointy bit), if you print with large diameter on the bed then all the forces are transmitted straightto the first layer and it will be liable to detach. If you print small diameter on the bed the the shrinkage tends to be absorbed in the structure.

I think I may need to reset the PINDA . ( tomorrow ) the machine was printing well till I did the filament feeder sensor modification . Then before I cold test it I got a dose of Covid / long covid , brain scrambled well & truly for several months. ( Honestly I' not normally this crazy or stupid

)

)As a result I'd left the machine unused for a year and in need of current updates .

What a PIA ,the printer was in my log cabin down the garden . Meantime my wife binned BT , changing over to Sky . Unfortunately I lost the internet signal out to it ...... despite trying two fairly cheap extenders with the Sky signal .

So I've have had to flit houses and bring it into the bungalow instead.

Everything is updated and the machine has been flashed with the latest programme. I've done the complete resetting of X Y&Z as per the Printer operators manual (POM) .

When the machine has done the first few inches of extruding after the insertion of the memory card & pressing the control knob GO it's nice & thick

Then by the time it's four inches long it reduces to 0.05 mm or so in diameter & height .....

It's usually moved across the bed plate and starts this spiderweb extrusion .....that is not fully laid on the plate ..by the time the nozzle has done two layers high this spider web all too often curls up , fouls the nozzle & tears free.

Been busy today but I have made some ABS juice liquid using scrap ABS and Aldi acetone paint thinners . So I now have that weapon in my armoury to stick the print down ready for when I've redrawn things using fusion 360 and the current slicer g codes.

I'll see if it works before altering /rechecking the PINDA as per the POM .

daedalusminos

Member

- Messages

- 2,401

- Location

- Norwich

What's the purge extrusion like front left of bed before it starts printing the model? Might be worth checking extruder tension.When the machine has done the first few inches of extruding after the insertion of the memory card & pressing the control knob GO it's nice & thick

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

It's a nice fat run about 1.7 mm wide with a rounded top that's securely stuck to the bed ... once it moves to the right after say 3 inches it reduces in diameter & height to around 0.5 mm & occasionally does not stick to the bed ..... the adhesion is erratic .. I can see under the extrusion .. there is around an A4 paper thickness gap . it then droops down on to th plate an inch or so behind the nozzles path .

This thin extrusion carries on discharging as the printer starts the actual print run . There are numerous times when it appears to fail to adhere & I can see light under it , by the time it's reached the third or fourth complete item print the print usually curls and catches , comes free of the plate.

I'm about to have a late tea , Once I've checked the Fusion & Prusa's slicer are fully up to date, I'm going to redraw in a different file , putting it on a plinth and reducing the infill , then get the G code & see if it prints any better .

I've managed to sent the print file to M C he'll be looking at it too.

If your happy to help I can let you have the current file if you PM me your email addy , as I can't seem to get it entered in on the thread .

This thin extrusion carries on discharging as the printer starts the actual print run . There are numerous times when it appears to fail to adhere & I can see light under it , by the time it's reached the third or fourth complete item print the print usually curls and catches , comes free of the plate.

I'm about to have a late tea , Once I've checked the Fusion & Prusa's slicer are fully up to date, I'm going to redraw in a different file , putting it on a plinth and reducing the infill , then get the G code & see if it prints any better .

I've managed to sent the print file to M C he'll be looking at it too.

If your happy to help I can let you have the current file if you PM me your email addy , as I can't seem to get it entered in on the thread .

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Moray ,  That's precisely what I've designed and exactly what I'm am after. Thanks a heck of a lot ..you are a gentleman & a scholar as far as I'm concerned .

That's precisely what I've designed and exactly what I'm am after. Thanks a heck of a lot ..you are a gentleman & a scholar as far as I'm concerned .

I'm using Prusa's own slicer , initially every time I tried to update if from Prusa's own library it flashed up a message at the end of the down load saying ," Some parts of the file could not be loaded " .

Contacted Prusa .. they sent me the Git hub link for the 2.3.1 version , had to tell windows defender to let it in , I down loaded it without problems , opened it up straight away & got the model in off Fusion360 via a file of my own .

I THEN LEVELLED IT to the plate .

I THEN LEVELLED IT to the plate .

Dadalusmino said the same as you .. told me to try levelling it ... Had to play at doing that for 1/2 an hour or so till the penny dropped . I didn't know you could or should high light the object till it went green then click the box in the drop down list on the left that shows the box tipping to the left to put it on its bottom face on the plate .

Dadalusmino said the same as you .. told me to try levelling it ... Had to play at doing that for 1/2 an hour or so till the penny dropped . I didn't know you could or should high light the object till it went green then click the box in the drop down list on the left that shows the box tipping to the left to put it on its bottom face on the plate .

Have now got the G code and put it on a memory card will give it a bash at printing them off first only one then in 10's

What worries me is will I remember it all in a few days time as I've got a lot of "Seniors memory moments stored away in my head somewhere " .

I'm about to start typing a few sheets ( Copy & pasting these posts ) up as a memory jogger & put them in heat sealed envelopes , just in case.

Thanks guys I'll post the results later on after I've done the printing.

TTFN

Dave

That's precisely what I've designed and exactly what I'm am after. Thanks a heck of a lot ..you are a gentleman & a scholar as far as I'm concerned .

That's precisely what I've designed and exactly what I'm am after. Thanks a heck of a lot ..you are a gentleman & a scholar as far as I'm concerned .

I'm using Prusa's own slicer , initially every time I tried to update if from Prusa's own library it flashed up a message at the end of the down load saying ," Some parts of the file could not be loaded " .

Contacted Prusa .. they sent me the Git hub link for the 2.3.1 version , had to tell windows defender to let it in , I down loaded it without problems , opened it up straight away & got the model in off Fusion360 via a file of my own .

I THEN LEVELLED IT to the plate .

I THEN LEVELLED IT to the plate .

Dadalusmino said the same as you .. told me to try levelling it ... Had to play at doing that for 1/2 an hour or so till the penny dropped . I didn't know you could or should high light the object till it went green then click the box in the drop down list on the left that shows the box tipping to the left to put it on its bottom face on the plate .

Dadalusmino said the same as you .. told me to try levelling it ... Had to play at doing that for 1/2 an hour or so till the penny dropped . I didn't know you could or should high light the object till it went green then click the box in the drop down list on the left that shows the box tipping to the left to put it on its bottom face on the plate .Have now got the G code and put it on a memory card will give it a bash at printing them off first only one then in 10's

What worries me is will I remember it all in a few days time as I've got a lot of "Seniors memory moments stored away in my head somewhere " .

I'm about to start typing a few sheets ( Copy & pasting these posts ) up as a memory jogger & put them in heat sealed envelopes , just in case.

Thanks guys I'll post the results later on after I've done the printing.

TTFN

Dave

Last edited:

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

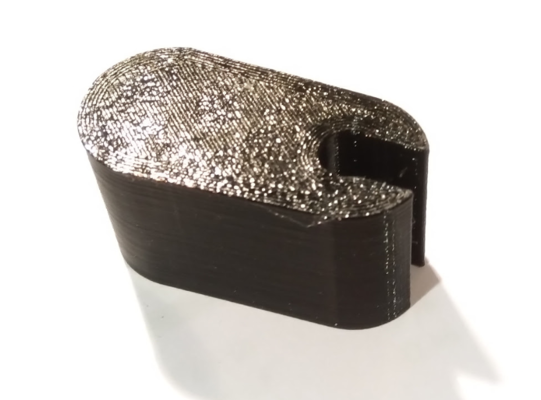

Well , well, well . the top finished surface of the latest test piece looks something like the designed 5 mm thick 19 mm square with an 8 mm hole plonked in it

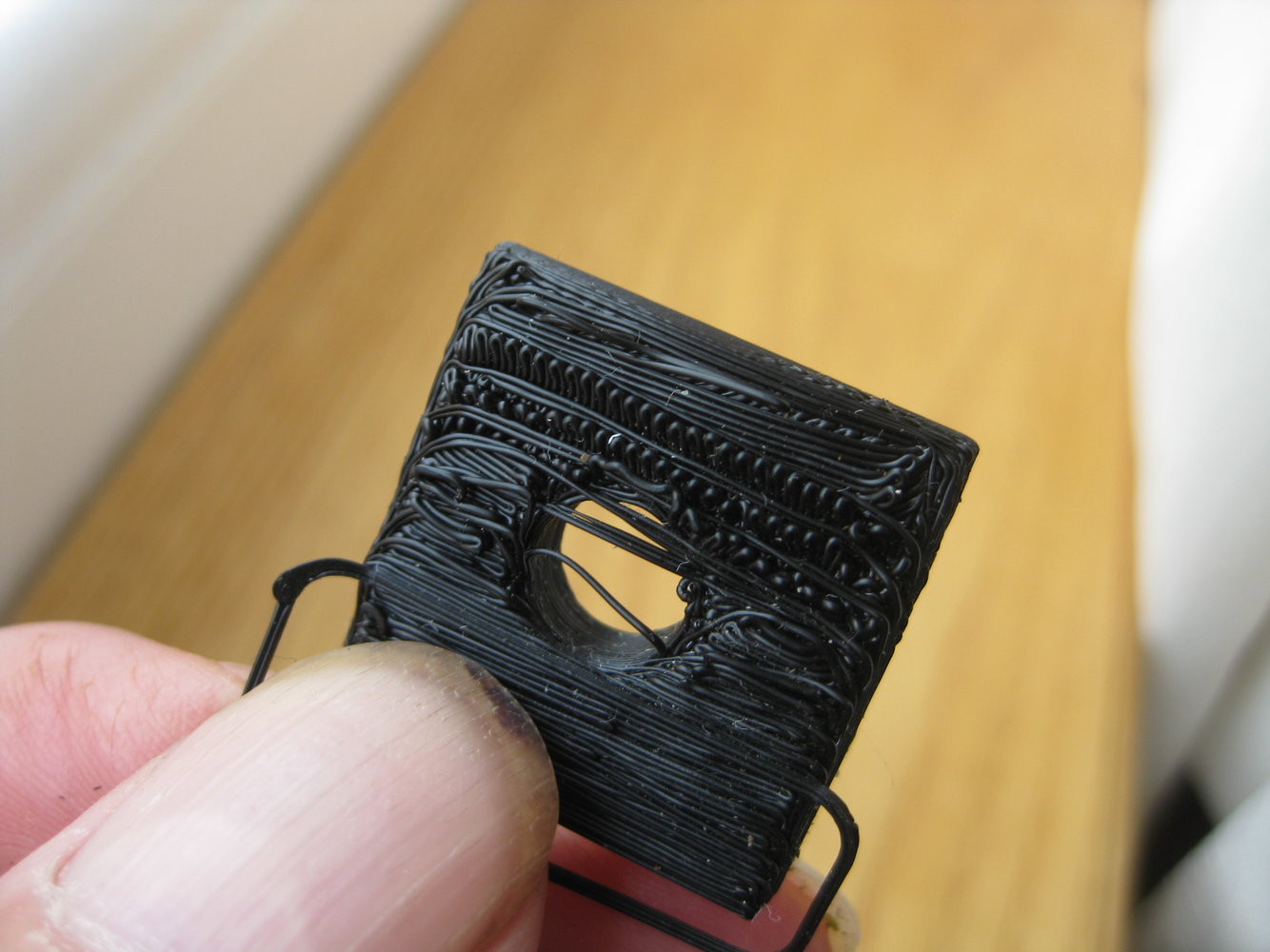

The second shot looks about 5 mm thick , but O my , o my , o my the last two show something quite different

the last two show something quite different

\G

The good news is using the home made ABS juice it did stick to the plate after a fashion . I'm making the solution a bit stronger ,having added all the mistakes in ABS to the original pot of mix , to see if it really was all down to one edge curling because of not sticking to the plate enough .

I'm also going to re-flash the printer with this afternoon's latest checked by me update , just incase things are a few bits & bytes out of sync from what's required. There's never a dull moment is there , when you're learning something complex & new ?

Ah well Rome wasn't built in a day & Davey boy didn't get a successful print first time ( And many other times ) round .

All comments including brilliant sarcasm & quality engineering solutions most welcome.

I'm off outside to give my pair of brain cells a rest and to do a bit of baby plant inserting in my raised veg beds

TTFN

Dave

PS .

I don't know what the handbag loop is attached to the test piece.. it's not my bag & I didn't design it in the drawing.

The second shot looks about 5 mm thick , but O my , o my , o my

the last two show something quite different

the last two show something quite different

\G

The good news is using the home made ABS juice it did stick to the plate after a fashion . I'm making the solution a bit stronger ,having added all the mistakes in ABS to the original pot of mix , to see if it really was all down to one edge curling because of not sticking to the plate enough .

I'm also going to re-flash the printer with this afternoon's latest checked by me update , just incase things are a few bits & bytes out of sync from what's required. There's never a dull moment is there , when you're learning something complex & new ?

Ah well Rome wasn't built in a day & Davey boy didn't get a successful print first time ( And many other times ) round .

All comments including brilliant sarcasm & quality engineering solutions most welcome.

I'm off outside to give my pair of brain cells a rest and to do a bit of baby plant inserting in my raised veg beds

TTFN

Dave

PS .

I don't know what the handbag loop is attached to the test piece.. it's not my bag & I didn't design it in the drawing.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,302

- Location

- Near to Cross Hands Llanelli SouthWales GB

Or is there something wrong with your slicer not putting the part level on the bed?

Thanks ,

As far as I could see I'd successfully laid the part on th bed of the slicer correctly as the finished top was OK and two edges looked OK .

But as it was 04.10 hrs when I did it this morning (

bloody dawn chorus

bloody dawn chorus carbon

Member

- Messages

- 3,063

- Location

- S. Glos. U.K

Well , well, well . the top finished surface of the latest test piece looks something like the designed 5 mm thick 19 mm square with an 8 mm hole plonked in it

The second shot looks about 5 mm thick , but O my , o my , o mythe last two show something quite different

\G

The good news is using the home made ABS juice it did stick to the plate after a fashion . I'm making the solution a bit stronger ,having added all the mistakes in ABS to the original pot of mix , to see if it really was all down to one edge curling because of not sticking to the plate enough .

I'm also going to re-flash the printer with this afternoon's latest checked by me update , just incase things are a few bits & bytes out of sync from what's required. There's never a dull moment is there , when you're learning something complex & new ?

View attachment 293296View attachment 293299View attachment 293298

View attachment 293297

Ah well Rome wasn't built in a day & Davey boy didn't get a successful print first time ( And many other times ) round .

All comments including brilliant sarcasm & quality engineering solutions most welcome.

I'm off outside to give my pair of brain cells a rest and to do a bit of baby plant inserting in my raised veg beds

TTFN

Dave

PS .

I don't know what the handbag loop is attached to the test piece.. it's not my bag & I didn't design it in the drawing.

In the first picture it looks like you are printing with a skirt, but the skirt doesn’t go around the complete part as it should. If the part isn’t flat in the bed I would have expected to see a small skirt around the first layer only which you seem to have. This will lead to a lot of bed adhesion problems as you are then only relying on a small area to hold it in place