- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I have just purchased a Boxford Lathe

- Thread starter 123hotchef

- Start date

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

The tang snaps off, so it's not a problem. In fact, you always snap the tang off to stop the stud or bolt jamming on it. It is 2BA I believe (may be 3/16 Whit. though)

If I have to drill the hole out anyway I may as well use a M6 helicoil and a nice new M6 bolt, I cant remember the last time I used a helicoil TBH

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

just googled dog point, well the one in there was a normal bolt that explains why it was hard to remove from the stud, I cleaned the stud up with a file now it slides on and off lovely. I guess I need to turn the end of a normal screw down to make it a dog point that can be my first job on the lathe I guess!Make sure it's a dog point screw or you'll burr tthe stud and make removal difficult.

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

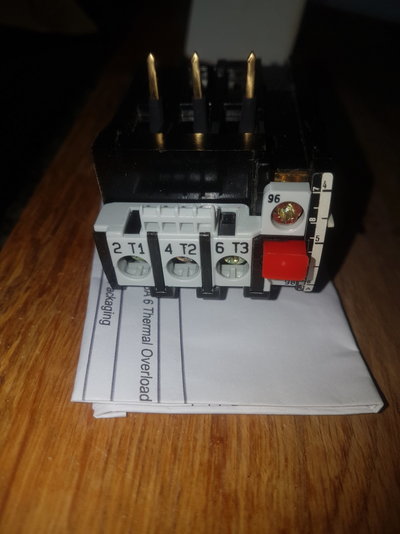

woo woo the overloader came today might get the lathe running properly tomorrow

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

It runs without cutting out now.

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

Does any one know the thread sizes of these the top 2 are not 1/8bsp they are much smaller. And the scraper is a fine pitch probably imperial are they

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

Could the bed scraper holes be 4BA whatever that is

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

Thanks I will try a 4mm tomorrow. Any idea on the grease cupsfor the scraper hole most probably 4BA, but try a 4mm screw in it

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

Grease cups - no, but you could give Boxford spares a call / email if you don't have a selection of old bolts to try.

i will try a m8 later it looks m8 size but i am sure it will be imperial. I know nothing about imperial bolt sizes.

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

i will try a m8 later it looks m8 size but i am sure it will be imperial. I know nothing about imperial bolt sizes.

I inherited a large cantilever tool box full of old bolts and machine screws. Been invaluable.

Even just finding on that fits o hole to put a thread gauge on is helpful.

Added to it over the years as I've stripped things down.

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

I inherited a large cantilever tool box full of old bolts and machine screws. Been invaluable.

Even just finding on that fits o hole to put a thread gauge on is helpful.

Added to it over the years as I've stripped things down.

That is another thing I need some thread gauges

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

There are no metric threads on the machine. Not at home to check at present but I think the graders may be BSF.

i didnt think there would be any metric threads its too old!

123hotchef

Member

- Messages

- 14,256

- Location

- Kent

4mm will fit in But it will knacked the threads if I tighten it upfor the scraper hole most probably 4BA, but try a 4mm screw in it

M4 has a pitch of 0.7mm usual OD is 3.9mm 60 deg angle

4BA has a 0.66mm pitch and 3.6mm nominal OD angle 47 deg

If M4 fits and screws (finger) in easily then I wouldn't worry about it, it will only be nipped up to keep the felt holder in place.

If it gets tight it's down to your local iron mongers for some 4BA.

4BA has a 0.66mm pitch and 3.6mm nominal OD angle 47 deg

If M4 fits and screws (finger) in easily then I wouldn't worry about it, it will only be nipped up to keep the felt holder in place.

If it gets tight it's down to your local iron mongers for some 4BA.