- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- CAD/CAM, 3D Printing and Laser Cutting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I've Gone and Done Something Mental

- Thread starter Parm

- Start date

Z-limit switch set too low, and then winding the bed down onto the springs to compensate.I am still struggling to figure out how your bed can be fouling the y-axis servo. Mine comes nowhere near.

And it's not a servo, it's stepper motor.

Pete.

Member

- Messages

- 14,832

- Location

- Kent, UK

Z-limit switch set too low, and then winding the bed down onto the springs to compensate.

The switch mount has a stop on it to prevent that. If you managed to mount it that low you would know that it was because you cut the stop lug off.

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

I am still struggling to figure out how your bed can be fouling the y-axis servo. Mine comes nowhere near.

Well it was. The range of adjustments meant that it was extremely close, however with new yellow springs, I have far better clearance. The originals were just far too weak in my opinion and would not allow the bed to be stable with the limit switch set at the standard height.

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

Today I have printed some lock pins for Scimitars. PLA didn't work too well, being quite brittle, but PETg seemed OK.

I have bought some ABS filament to play with. Lots of warnings everywhere about how difficult it is to print and the special adhesives etc required, but my ABS Benchy is halfway through with no issues so far. Bed at 110C and nozzle at 230C. We will see.

I have bought some ABS filament to play with. Lots of warnings everywhere about how difficult it is to print and the special adhesives etc required, but my ABS Benchy is halfway through with no issues so far. Bed at 110C and nozzle at 230C. We will see.

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

The pins are PETg but I may try it with the ABS Benchy. I have just checked on it and it is looking good so far.

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

It depends what bed you're using. If you use a glass or similar thickness bed, you have to move the limit switch up from the stop, otherwise you could get the problem of the bed catching the rear stepper.The switch mount has a stop on it to prevent that. If you managed to mount it that low you would know that it was because you cut the stop lug off.

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

It seems that we are back to the bed level variations again. Even with the BL Touch it's not right. I did a quick ABS print using the settings from the Benchy and found that the rear / left portion of the skirt wouldn't print, even though it is set to four lines. I re-levelled to find that it was again well out, so I spent some time getting it just so again. The subsequent print showed exactly the same issue. The same part of the completed print released with a strange white stain underneath. Most likely the 3DLAC I would guess.

Incidentally, the reason that I had to reprint this part is because the PLA version warped in the car over last week's warm weather. This one is ABS. I also now have some PETg transparent to remake the lens.

Incidentally, the reason that I had to reprint this part is because the PLA version warped in the car over last week's warm weather. This one is ABS. I also now have some PETg transparent to remake the lens.

JMS1972

Member

- Messages

- 1,209

- Location

- NW Leicestershire, UK

Are you levelling the bed when it is hot? Could be warping slightly when hot.It seems that we are back to the bed level variations again. Even with the BL Touch it's not right. I did a quick ABS print using the settings from the Benchy and found that the rear / left portion of the skirt wouldn't print, even though it is set to four lines. I re-levelled to find that it was again well out, so I spent some time getting it just so again. The subsequent print showed exactly the same issue. The same part of the completed print released with a strange white stain underneath. Most likely the 3DLAC I would guess.

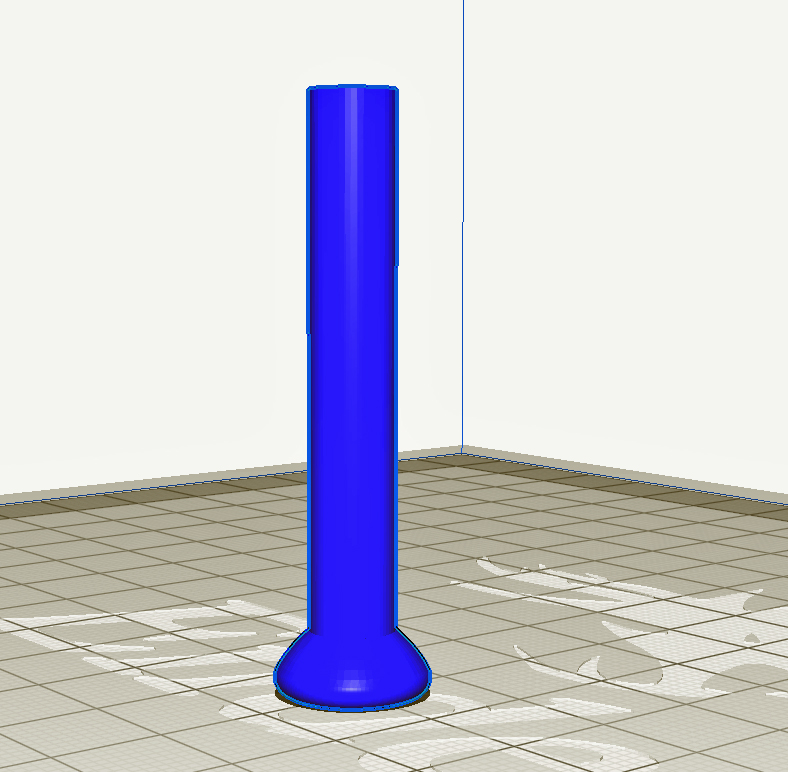

View attachment 310528

Incidentally, the reason that I had to reprint this part is because the PLA version warped in the car over last week's warm weather. This one is ABS. I also now have some PETg transparent to remake the lens.

I found going to a glass bed sorted most if my levelling issues (ally bed was bowed)...

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,589

- Location

- Sevenoaks, UK

Borosilicate glass top here. Levelled using feeler gauges in the end. My lad will print a pla phone holder to go out, forget about it and leave in the car where it warps. He'll print another when he next goes out!

Can't get him to play with ABS here as he's worried about the heat damaging the internal electronics of the printer. Doesn't seem to be interested in moving it outboard either.

Can't get him to play with ABS here as he's worried about the heat damaging the internal electronics of the printer. Doesn't seem to be interested in moving it outboard either.

JMS1972

Member

- Messages

- 1,209

- Location

- NW Leicestershire, UK

I use this file to finesse bed levelling. You tweak the adjusters whilst this is printing. So you see the actual results in real time

www.thingiverse.com

www.thingiverse.com

Ender 3 Bed Level by Elproducts

9/1/2020: I've increased the speed and created two versions. A version that uses M0 GCode pause for 8-Bit Ender 3 (V1.x.x board) and an M25 GCode pause version for 32 Bit machines (Ender V2 and Ender 3, Ender 3 Pro with 4.2.x board).These are in the V4.0 .zip file.8/13/2020:I've reduced the...

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

I have a Borosilicate bed and always level stinging hot, so at working temperature. I will have to spend some time going through it again. Luckily that print is usable.Are you levelling the bed when it is hot? Could be warping slightly when hot.

I found going to a glass bed sorted most if my levelling issues (ally bed was bowed)...

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

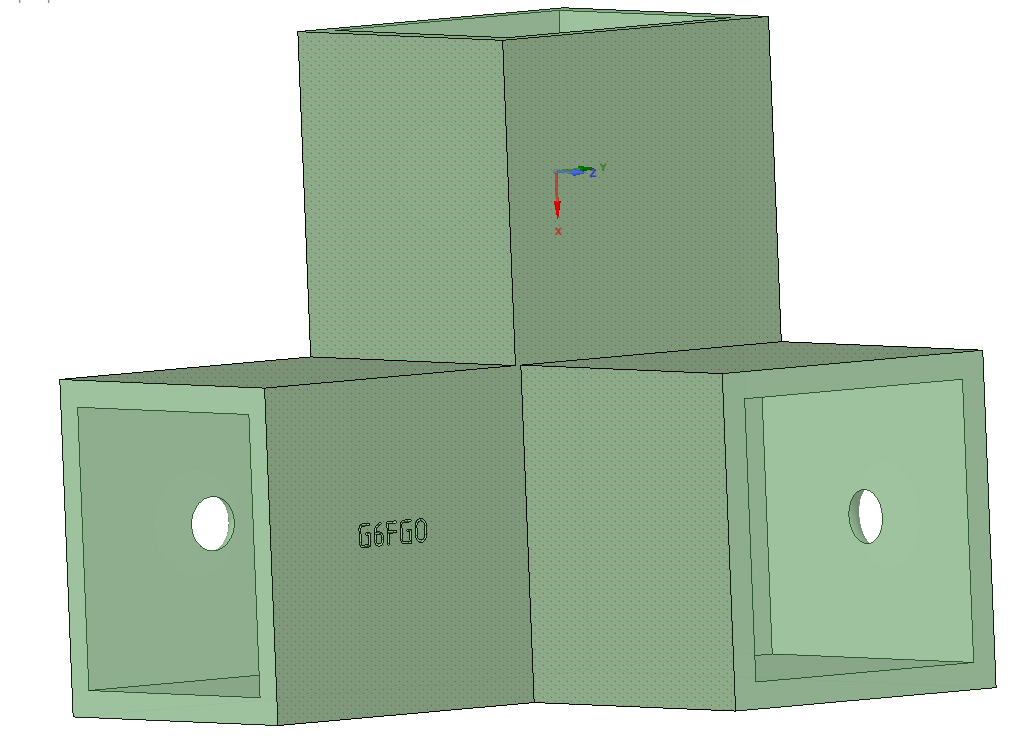

Things seem to be going fairly well with the eSun ABS. Nozzle temperature 235C and bed temperature 110C. Z offset with the BL Touch is 3.4 which seems to give a nice first layer. Cooling fan turned off in the slicer.

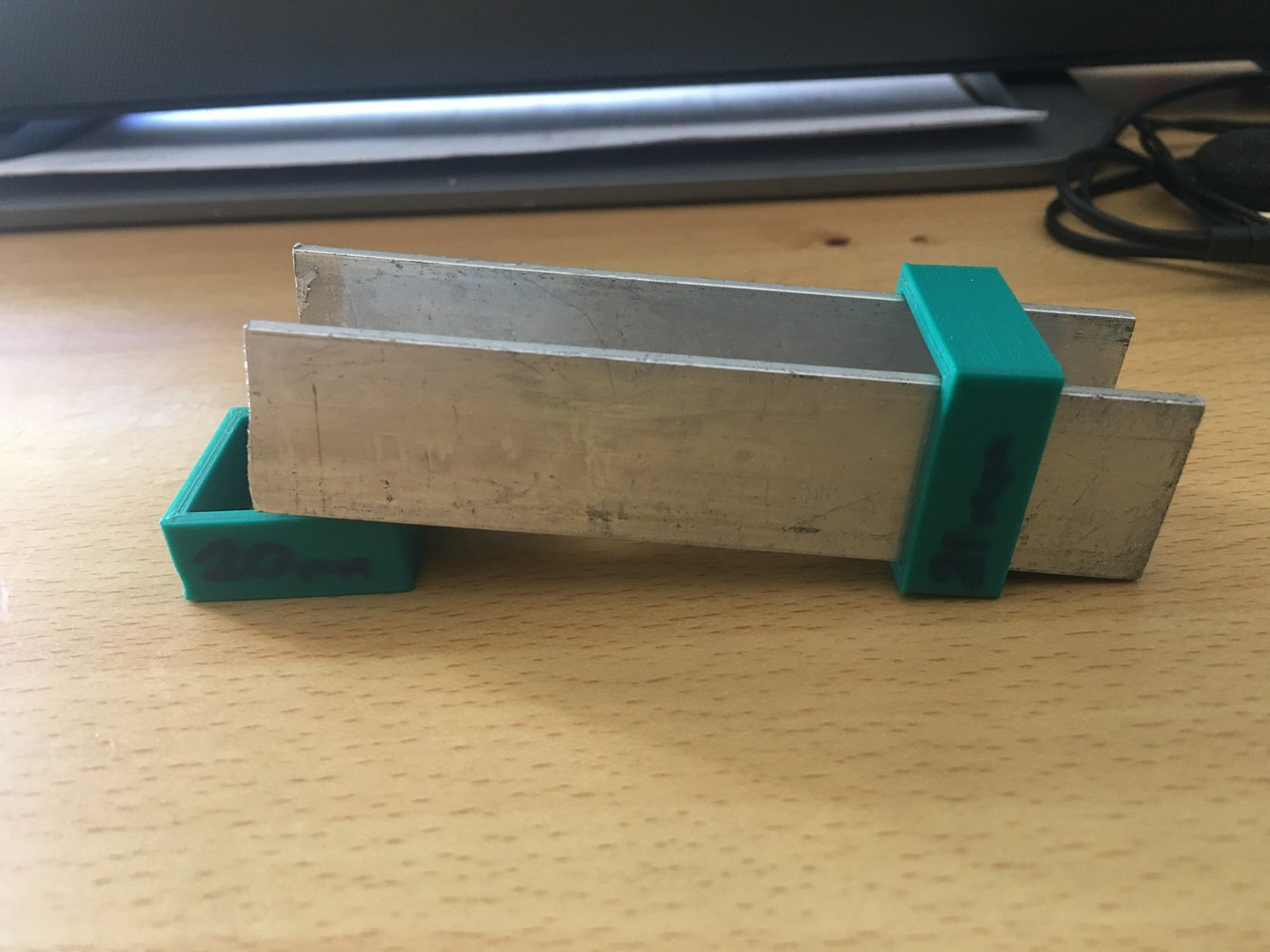

I have printed a few test pieces to gauge the size needed to join some aluminium extrusion for a printer enclosure. Those are perfectly formed so I will start a real print shortly and see if the settings 20.9 by 20.1 remain consistent.

I have printed a few test pieces to gauge the size needed to join some aluminium extrusion for a printer enclosure. Those are perfectly formed so I will start a real print shortly and see if the settings 20.9 by 20.1 remain consistent.

Last edited:

ajlelectronics

Member

- Messages

- 10,766

- Location

- Gloucester, England

Oh dear, bang goes my fine tolerances!

MattF

Forum Supporter

- Messages

- 17,595

- Location

- South Yorkshire