You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your best welding

- Thread starter Jlg

- Start date

Liquid Metal

Member

- Messages

- 482

- Location

- Essex, UK

Lovely looking root penetration ! How many passes ? From your post i make that 5 passes ?

How long does it take to do one weld ?

5 yes. Root pass, two fill passes to bring it up just under flush, then two capping passes.

Can be done in 4 (single pass cap) or even 3, but it distorts a lot, and risks lack of fusion between runs.

As far as how long? Once cut prepped, tacked and purged... id say around 45 mins, as was giving it time to cool due to interpass temps and brushing it well in between each pass.

Liquid Metal

Member

- Messages

- 482

- Location

- Essex, UK

Was fixed position 6g, as was a code prolongation test. I find it easier doing it on butts than fillets tbh when it comes to capping passes. Easy enough, just dont put too much pressure through the torch or itll just slip off.

Rooting and filling though i prefer to do it freehand. Feels like have better control, especially welding roots.

Rooting and filling though i prefer to do it freehand. Feels like have better control, especially welding roots.

zeppelin builder

Member

- Messages

- 2,166

- Location

- peoples republic of scotland

View attachment 164928 View attachment 164929

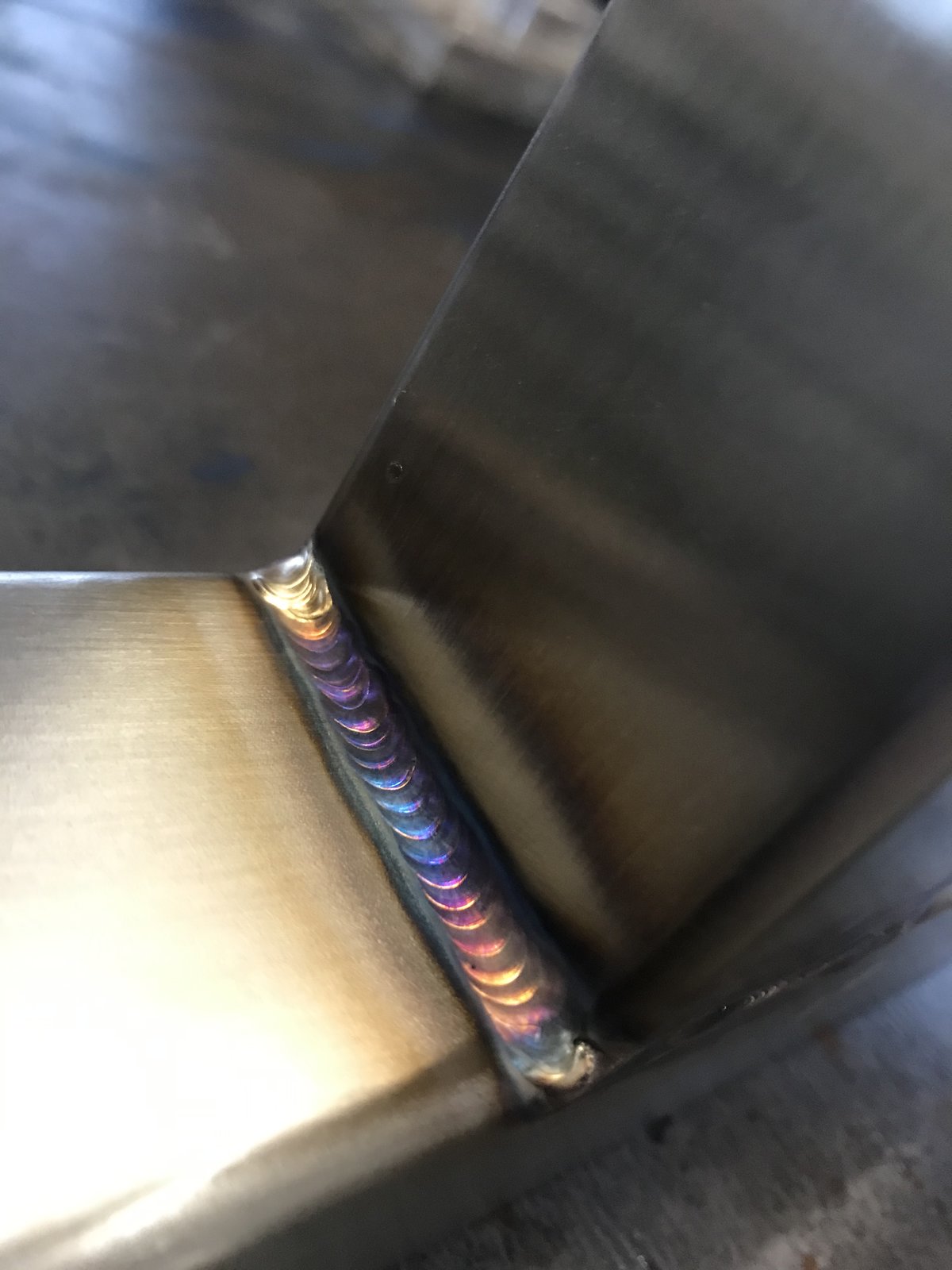

316 Stainless prolongation test this week, done on 3" sched 80.

10l/min purge, 3.2mm root gap no landing. 1.6mm wire 80amps freehand. Size 5 ceramic.

Filled freehand with 2.4wire both passes,

Cap passes were walked with 90amps, size 8 ceramic and 2.4mm wire.

nice but why did you do the upper pass first on the far side ? we would normaly do the bottom run first then the top one or is it just a bit over fill that you going to wash in

zeppelin builder

Member

- Messages

- 2,166

- Location

- peoples republic of scotland

Was fixed position 6g, as was a code prolongation test. I find it easier doing it on butts than fillets tbh when it comes to capping passes. Easy enough, just dont put too much pressure through the torch or itll just slip off.

Rooting and filling though i prefer to do it freehand. Feels like have better control, especially welding roots.

the ripples are all going in one direction on the picture of the root ie from 5 o clock clock wise bad pick up at 7 oclock and the tie in i take it thats it at 5 o clock is not too great

some inspectors insist you start at 6 and finish at 12 other wise they deem you to be welding vertical down

Richard.

Member

- Messages

- 18,344

- Location

- Cambridgeshire

I was wondering the same thing zep.

That doesn’t look a fixed position joint to me either as the stop meets the **** end of the start.

Lovely looking joint and the internal penetration is bang on but I’d expect to see the two stop points kissing around TDC from either direction.

That doesn’t look a fixed position joint to me either as the stop meets the **** end of the start.

Lovely looking joint and the internal penetration is bang on but I’d expect to see the two stop points kissing around TDC from either direction.

Liquid Metal

Member

- Messages

- 482

- Location

- Essex, UK

The quick description was of the bottom photo, not both. I prefer to freehand a root for a test but i can confidently say it would not be that even lol

The root was part of another job, 4" sch40, but walked and rolled

Sorry, i should have said that in the first place lol....wasnt misleading at all was it

See what you mean now reading it again.

The root was part of another job, 4" sch40, but walked and rolled

Sorry, i should have said that in the first place lol....wasnt misleading at all was it

See what you mean now reading it again.

Liquid Metal

Member

- Messages

- 482

- Location

- Essex, UK

nice but why did you do the upper pass first on the far side ? we would normaly do the bottom run first then the top one or is it just a bit over fill that you going to wash in

Was a straighter line to follow on the upper pass so i could keep it straighter. When i filled it, came up almost flush on the lower side when was filled, and thought would have struggled to keep it in a straight line. I know it wasnt done strictly correctly but was ok and passed testing anyway, so still jave a job lol

Liquid Metal

Member

- Messages

- 482

- Location

- Essex, UK

One pic i have got of something i was mucking about with a while ago though was this one. Cant remember if i posted it on here, might have done? Had a go at making a wood burner for the back garden out of some offcuts at work. Never got around to finishing it off though. Might do at some point though.

Forgive the whopping big gaps around the two branches though, marking out and cutting angled branches in pipes isnt my strong suit as can be seen lol

Forgive the whopping big gaps around the two branches though, marking out and cutting angled branches in pipes isnt my strong suit as can be seen lol

zeppelin builder

Member

- Messages

- 2,166

- Location

- peoples republic of scotland

I was wondering the same thing zep.

That doesn’t look a fixed position joint to me either as the stop meets the **** end of the start.

Lovely looking joint and the internal penetration is bang on but I’d expect to see the two stop points kissing

Was a straighter line to follow on the upper pass so i could keep it straighter. When i filled it, came up almost flush on the lower side when was filled, and thought would have struggled to keep it in a straight line. I know it wasnt done strictly correctly but was ok and passed testing anyway, so still jave a job lol

we do what we have to do ,glad it passed

its obvious you can weld so keep at it

zeppelin builder

Member

- Messages

- 2,166

- Location

- peoples republic of scotland

One pic i have got of something i was mucking about with a while ago though was this one. Cant remember if i posted it on here, might have done? Had a go at making a wood burner for the back garden out of some offcuts at work. Never got around to finishing it off though. Might do at some point though.

Forgive the whopping big gaps around the two branches though, marking out and cutting angled branches in pipes isnt my strong suit as can be seen lolView attachment 165128

thats very artistic it could be a rustic 6g welding fixture, just tack test piece on the end of that branch

Liquid Metal

Member

- Messages

- 482

- Location

- Essex, UK

Liquid metal, That tree effect looks spot on, superb!

Realised quite quickly at the time, it wasnt the easiest thing to do to run welds all over the place like that, not after spending 15yrs trying to stay in a straight line lol.

Richard.

Member

- Messages

- 18,344

- Location

- Cambridgeshire

I’ll second that. The bark effect you’ve got going on with the knots looks really brilliantRealised quite quickly at the time, it wasnt the easiest thing to do to run welds all over the place like that, not after spending 15yrs trying to stay in a straight line lol.

Guitardaz69

New Member

- Messages

- 3

- Location

- Halifax uk

Germanmachinist

Member

- Messages

- 35

- Location

- Germany

What a beautiful Thread:

my sweetest welds from the last Time

my sweetest welds from the last Time