You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your welding cart/trolley...

- Thread starter arthur

- Start date

daleyd

Member

- Messages

- 10,380

- Location

- Wrexham, North Wales

At a guess some do, some don't. As a fair proportion are probably used lightly by hobby type users I'd imagine they wouldn't get as choked up as as heavily or as quickly as ones used in a busy fab shop.

I've had mine for 3 years and I had the back off it the other day to tighten up the gas connection and it looked pretty clean inside, so much so I didn't even bother giving it a clean.

I've had mine for 3 years and I had the back off it the other day to tighten up the gas connection and it looked pretty clean inside, so much so I didn't even bother giving it a clean.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,637

- Location

- Keeler crater

I've never done it . But in my defense, it's an IFL in their stupid curvy plastic case (I doubt they come apart easily) and I don't have a compressor. I did unscrew the front panel a few weeks ago and it was absolutely full of dust, it really needs doing.

. But in my defense, it's an IFL in their stupid curvy plastic case (I doubt they come apart easily) and I don't have a compressor. I did unscrew the front panel a few weeks ago and it was absolutely full of dust, it really needs doing.

. But in my defense, it's an IFL in their stupid curvy plastic case (I doubt they come apart easily) and I don't have a compressor. I did unscrew the front panel a few weeks ago and it was absolutely full of dust, it really needs doing.

. But in my defense, it's an IFL in their stupid curvy plastic case (I doubt they come apart easily) and I don't have a compressor. I did unscrew the front panel a few weeks ago and it was absolutely full of dust, it really needs doing.roofman

Purveyor of fine English buckets and mops

- Messages

- 12,942

- Location

- North West with water on 3 sides

Ive fitted an extra fan low down on my SAF and it does chase some air though...That might be a little on the OCD side yeah

skotl

Forum Supporter

- Messages

- 10,393

- Location

- Edinburgh, UK

Indeed. I drape my plasma and welder before I do any grinding / cutting.At a guess some do, some don't. As a fair proportion are probably used lightly by hobby type users I'd imagine they wouldn't get as choked up as as heavily or as quickly as ones used in a busy fab shop.

I've had mine for 3 years and I had the back off it the other day to tighten up the gas connection and it looked pretty clean inside, so much so I didn't even bother giving it a clean.

And I do get stuck about them with a vacuum ~monthly.

But as daleyd suggests, I'm not using any of the kit any more than "lightly" (perhaps 2 hours a week).

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

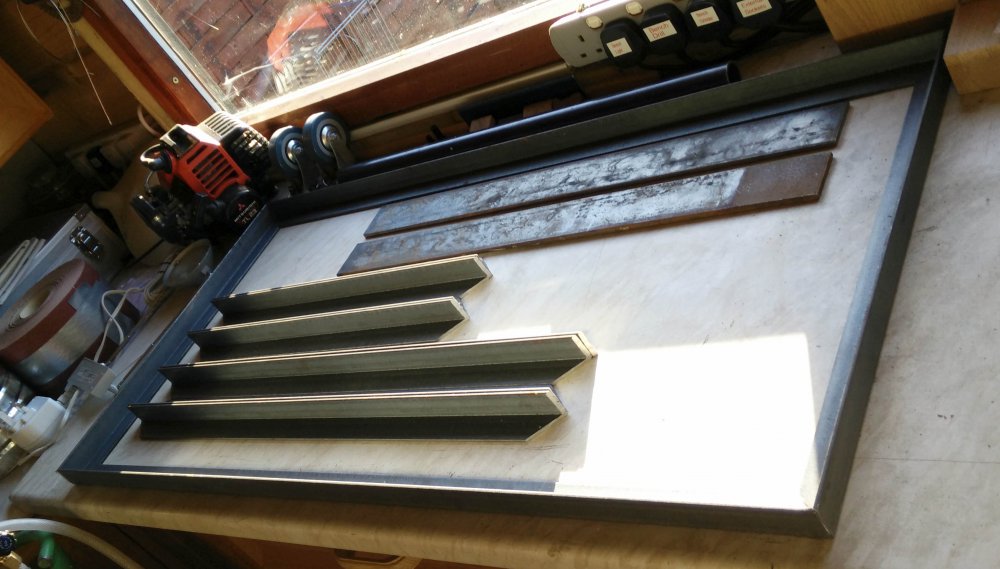

Now that I've got my new saw up and running [separate thread re Evo saws], I spent the afternoon measuring [ many times, so as not to get it wrong and waste material  ], cutting and mitring the angle iron for my welding trolley. Got enough done for the three shelves, castors cross brace/support and the handle.

], cutting and mitring the angle iron for my welding trolley. Got enough done for the three shelves, castors cross brace/support and the handle.

This is all planned out in my head [I don't do plans/diagrams ] and I'm ashamed to say I've had the steel lying in the shed for ages

] and I'm ashamed to say I've had the steel lying in the shed for ages  - this project has a gestation period longer than an African elephant......

- this project has a gestation period longer than an African elephant......

Next step is the welding but I'm reliant on doing it outside, so the weather will now dictate progress - don't be holding your collective breathes.......

but I'm reliant on doing it outside, so the weather will now dictate progress - don't be holding your collective breathes.......

At least progress has been made.

], cutting and mitring the angle iron for my welding trolley. Got enough done for the three shelves, castors cross brace/support and the handle.

], cutting and mitring the angle iron for my welding trolley. Got enough done for the three shelves, castors cross brace/support and the handle.This is all planned out in my head [I don't do plans/diagrams

] and I'm ashamed to say I've had the steel lying in the shed for ages

] and I'm ashamed to say I've had the steel lying in the shed for ages  - this project has a gestation period longer than an African elephant......

- this project has a gestation period longer than an African elephant......

Next step is the welding

but I'm reliant on doing it outside, so the weather will now dictate progress - don't be holding your collective breathes.......

but I'm reliant on doing it outside, so the weather will now dictate progress - don't be holding your collective breathes.......

At least progress has been made.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

Got the frames for the shelves welded up today, shows that modern inverter machines allow numpties like me to get half-decent results [let's not start the R-Tech debate again please  ]

]

This is my first real attempt at a project, apart from running beads on scrap [oh, and the rubbish steel table top ......

......

And this demonstrates that it's pointless buying cheap grinding discs - although this nameless wonder came with the grinder when I bought it.......

Next up, organise the corner uprights after measuring the shelf spacing maaaany times........

]

]This is my first real attempt at a project, apart from running beads on scrap [oh, and the rubbish steel table top

......

......And this demonstrates that it's pointless buying cheap grinding discs - although this nameless wonder came with the grinder when I bought it.......

Next up, organise the corner uprights after measuring the shelf spacing maaaany times........

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

Lovely job I must say mate but that grinding disc looks like it's broke down like that due to improper use.

You weren't running it into anything were you or trying to cut with it. I've seen lots of cheap nasty cutting discs break but a grinding disc either goes through abuse or its cracked before use.

You weren't running it into anything were you or trying to cut with it. I've seen lots of cheap nasty cutting discs break but a grinding disc either goes through abuse or its cracked before use.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

You weren't running it into anything were you or trying to cut with it.

No and no, just grinding on the flat.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

How old was it? Grinding discs have a use by date.

Bought the grinder in the first half of last year iirc, it came with it.

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

Me too. I've only ever bust cutting discs and usually by cutting something then quickly removing the burr with it (lazy and not swapping to correct disc)I've not seen an 'out of date' disc fail - not to say it won't happen...

I've seen them fail in that manner if they're wet or if they've been dropped though.

Edit - and overtightened/with no shims too, nearly forgot that. -- I've only ever had cutting discs fail on me, and that was entirely my own fault for cutting incorrectly supported tube...

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

I've only ever bust cutting discs

This was a grinding disc.

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

I know that's why it surprised me as they take some force to smash them. I believe you mate I'm just shocked as I've not seen one break like that before. I've had small chunks come off the outer diameter before making them run like a bag of **** but never properly smash up like that. Your lucky it didn't fling a bit out at you. Any way back to the trolley. It's a blinding job and the welding looks great.This was a grinding disc.

Last edited by a moderator:

lincoln2013

Member

- Messages

- 126

View attachment 79923

Nice looking job first one I have seen with a strimmer engine fitted to it though.

Nice looking job first one I have seen with a strimmer engine fitted to it though.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

View attachment 79923

Nice looking job first one I have seen with a strimmer engine fitted to it though.

Thanks, thought it'd save me dragging it about.......

The engine was off a sprayer which I had to junk after the big tank sprang a leak.

The engine was off a sprayer which I had to junk after the big tank sprang a leak.

I do. Every couple of months the covers come off off mine. She's sparkling inside.

I do. Every couple of months the covers come off off mine. She's sparkling inside.